Method of manufacturing metal composite plate for cutting tool

A metal clad plate and manufacturing method technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problem of low bonding strength, high technical level requirements, limited bimetal/multi-metal clad plate output and application range, etc. problems, to achieve the effect of less investment in equipment, greater economic benefits, and excellent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The method of the invention can produce composite steel plates with a thickness of 3 mm to 50 mm and a width of 1000 mm to 4000 mm, and composite steel strips with a thickness of 1 mm to 10 mm and a width of 230 mm to 4000 mm depending on the capacity of the rolling mill.

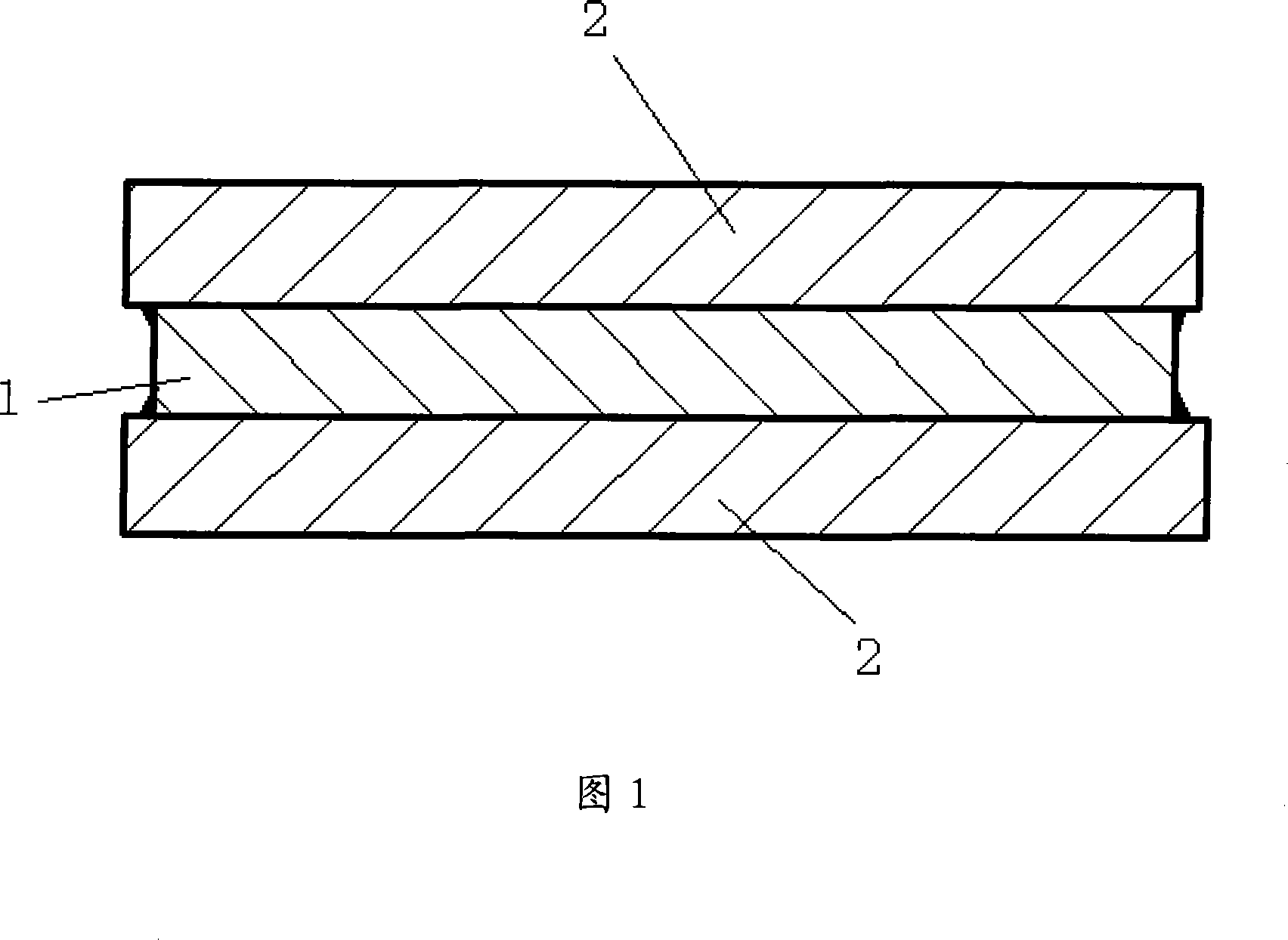

[0020] Manufacture 3.0mm×1000mm×10000mm, three-layer stainless steel composite plate for cutting tools with a finished substrate thickness of 0.3mm. The substrate blank is AISI440A stainless steel of 3.5mm×1000mm×2500mm, and the double plate blank is AISI304 stainless steel of 20mm×1010mm×2520mm. First use a special metal cleaner to clean the surface of the base and double board, rinse with water and dry, then soak in hydrochloric acid with a concentration of 21-30% for a period of time, rinse and dry, and then put it on a sandblasting machine for sandblasting. In order to activate the surface atoms while cleaning the surface, it is beneficial to the combination during rolling. As shown in Figure 1,...

Embodiment 2

[0022] Manufacture 3.0mm×1100mm×10000mm, three-layer stainless steel composite plate for cutting tools with a finished substrate thickness of 0.5mm. The substrate blank is 9Cr18Mo steel of 5.0mm×1100mm×2500mm, and the double plate blank is 1Cr13 stainless steel of 13.0mm×1110mm×2520mm. First use a special metal cleaner to clean the surface of the base and double board, rinse with water and dry, then soak in dilute sulfuric acid with a concentration of 17-20% for a period of time, rinse and dry, and then put it on the sandblasting machine for sandblasting , so as to activate the surface atoms while cleaning the surface, which is beneficial to the combination during rolling. As shown in Figure 1, the surfaces to be compounded of the substrate blank 1 and the doubler blank 2 are superimposed, and the contact edges of the base and doubler blanks are spot-welded every 50mm for initial fixation, and then the base and doubler panels are bonded with a 2000t press. Squeeze out the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com