Polymer mortar face outside wall heat-insulating board and preparing technique thereof

An external wall thermal insulation board and polymer technology, which is applied in the field of external wall thermal insulation boards for building decoration, can solve problems such as falling off, hidden dangers of sticking benzene board hanging net process, damage to external decoration, etc., and achieves strong plasticity and is conducive to the renovation of old houses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0012] Example 1 A polymer mortar surface insulation board for external walls, including polystyrene foam board (EPS) or polystyrene extruded board (XPS), polystyrene foam board (EPS) or polystyrene extruded board (XPS ) is the bottom surface ash, the outside of the bottom surface ash is mesh cloth, and the top of the mesh cloth is a reinforced polymer mortar layer. The bottom surface ash thickness is 1.5mm. The thickness of reinforced polymer mortar layer is 3mm.

[0013] The reinforced polymer mortar layer mortar is composed of the following formula by weight: 5 kg of rubber powder, 1 kg of lignin, 0.1 kg of tensile fiber, 100 kg of 425R cement, 200 kg of 40 mesh of quartz sand, and 5 kg of heavy calcium; the total of the above raw materials Synthesize glue with water at a weight ratio of 1:5.

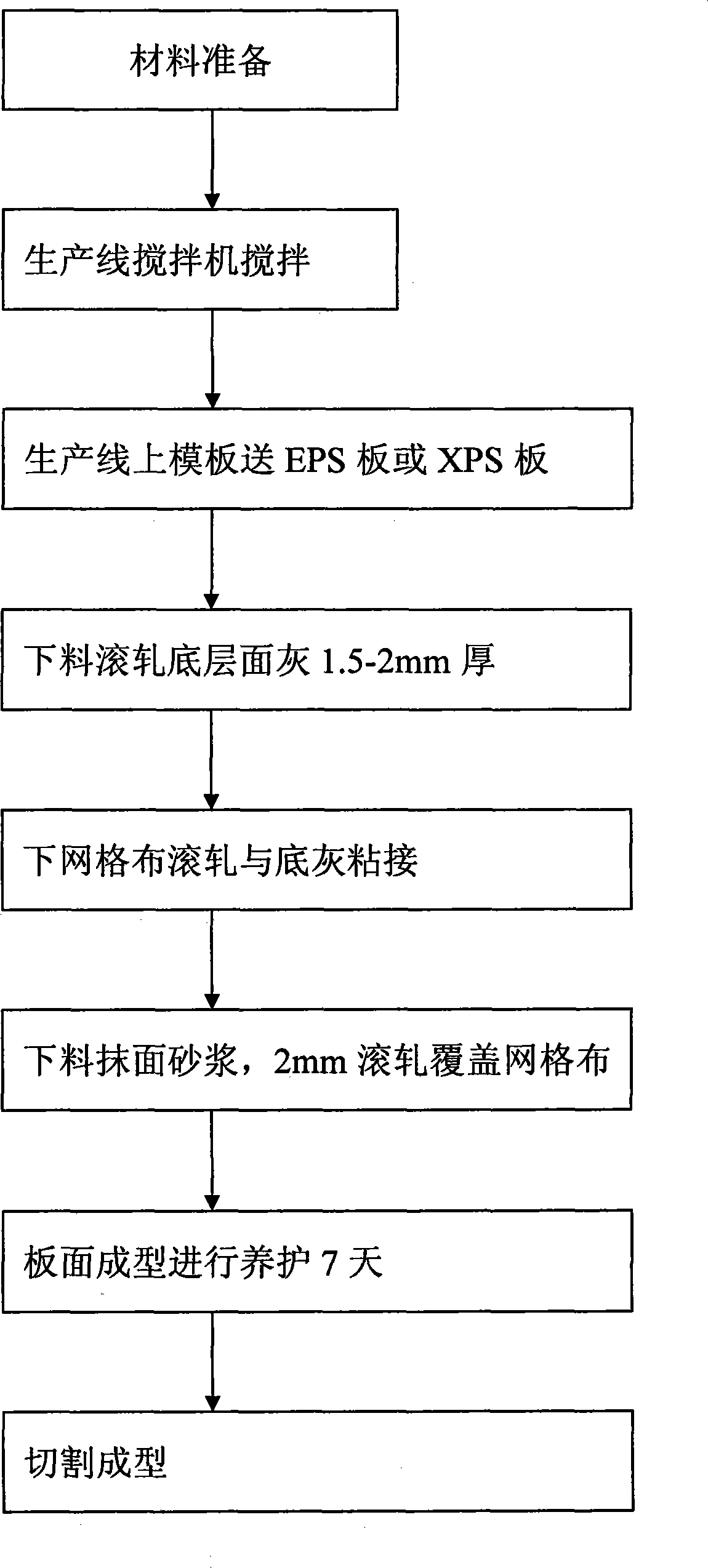

[0014] Referring to accompanying drawing 1, the preparation process of the polymer mortar surface external wall insulation board mainly includes the following steps: material prepa...

example 2

[0015] Example 2 A polymer mortar surface insulation board for external walls, including polystyrene foam board (EPS) or polystyrene extruded board (XPS), polystyrene foam board (EPS) or polystyrene extruded board (XPS) ) is the bottom surface ash, the outside of the bottom surface ash is mesh cloth, and the top of the mesh cloth is a reinforced polymer mortar layer. The bottom surface ash thickness is 2mm. The thickness of reinforced polymer mortar layer is 2mm.

[0016] The reinforced polymer mortar layer mortar is composed of the following formula by weight: rubber powder 10kg, lignin 0.1kg, tensile fiber 1kg, 425R cement 50kg, quartz sand 70 mesh 100kg, heavy calcium 20kg; the total of the above raw materials Synthesize glue with water at a weight ratio of 1:5.

[0017] The preparation process of the polymer mortar-faced external wall insulation board is the same as above.

[0018] Example 3 A polymer mortar surface insulation board for external walls, the structure is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com