Hemming machine for sewing trousers bottom

A technology of reel machine and trouser leg, applied to sewing machine components, sewing machine control devices, sewing equipment, etc., can solve the problems of complex structure, frequent mechanical failure, difficult cloth, needle synchronization, etc., achieve reasonable force transmission structure, reduce Damage rate, effect of avoiding needle dragging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

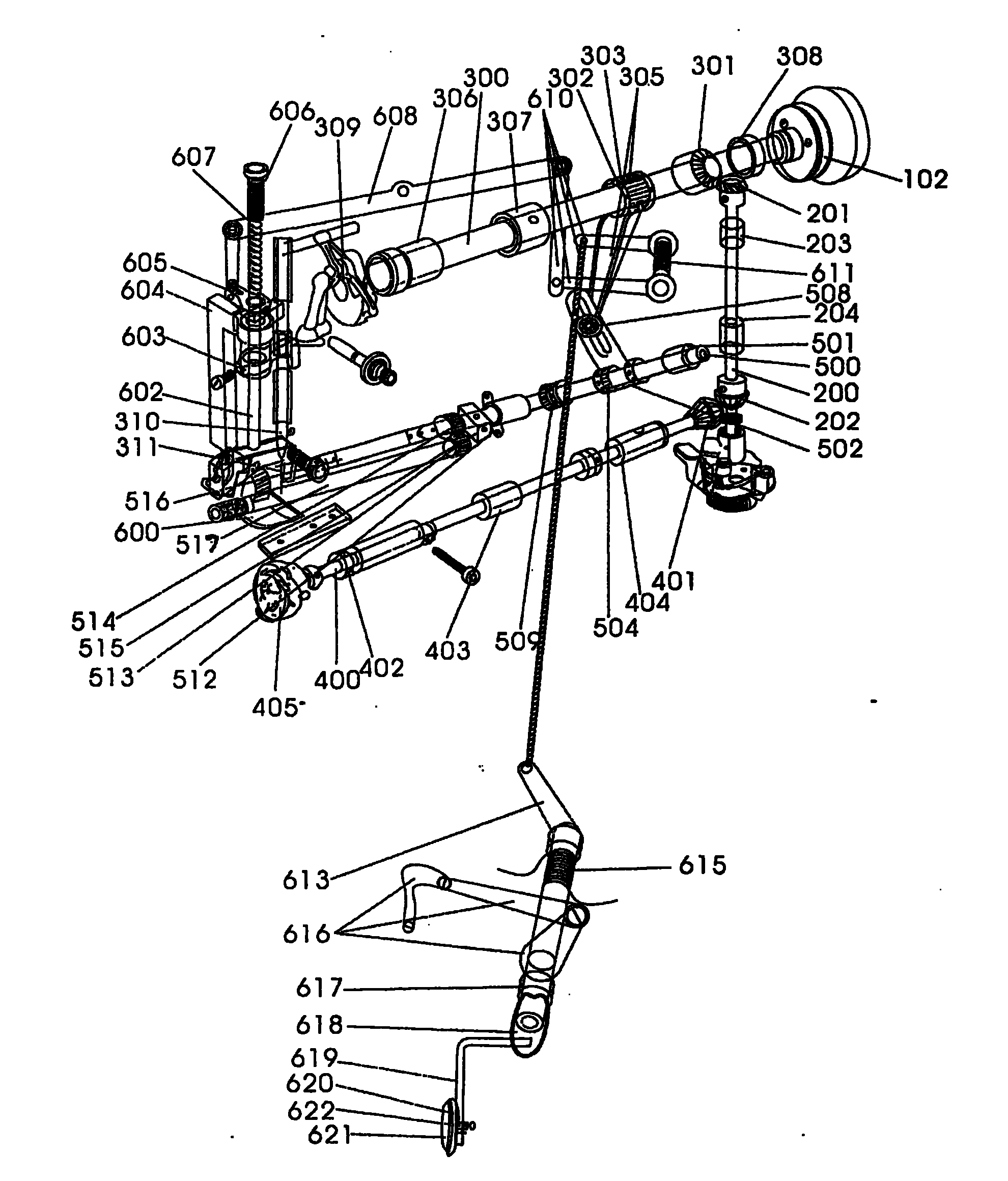

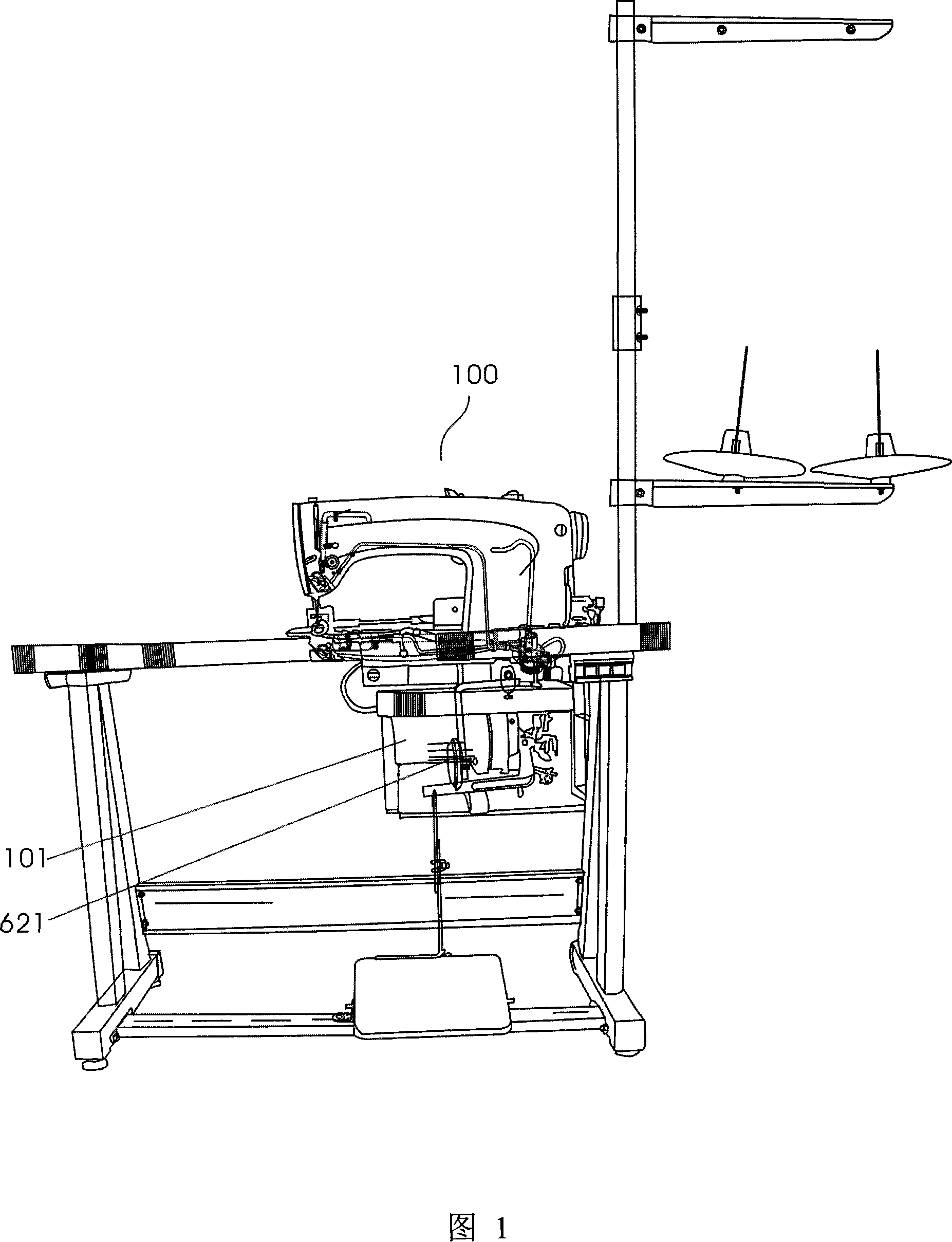

[0020] Fig. 1 is a schematic view of the front appearance of a wheel machine for sewing trouser legs according to the present invention. The present invention is an improvement to the existing roller foot machine, which improves the partial structure inside the integral machine head 100 and adds a lubricating oil supply pipeline. The knee block pad 621 in the knee control mechanism is located at the position where the operator's knee is convenient to touch.

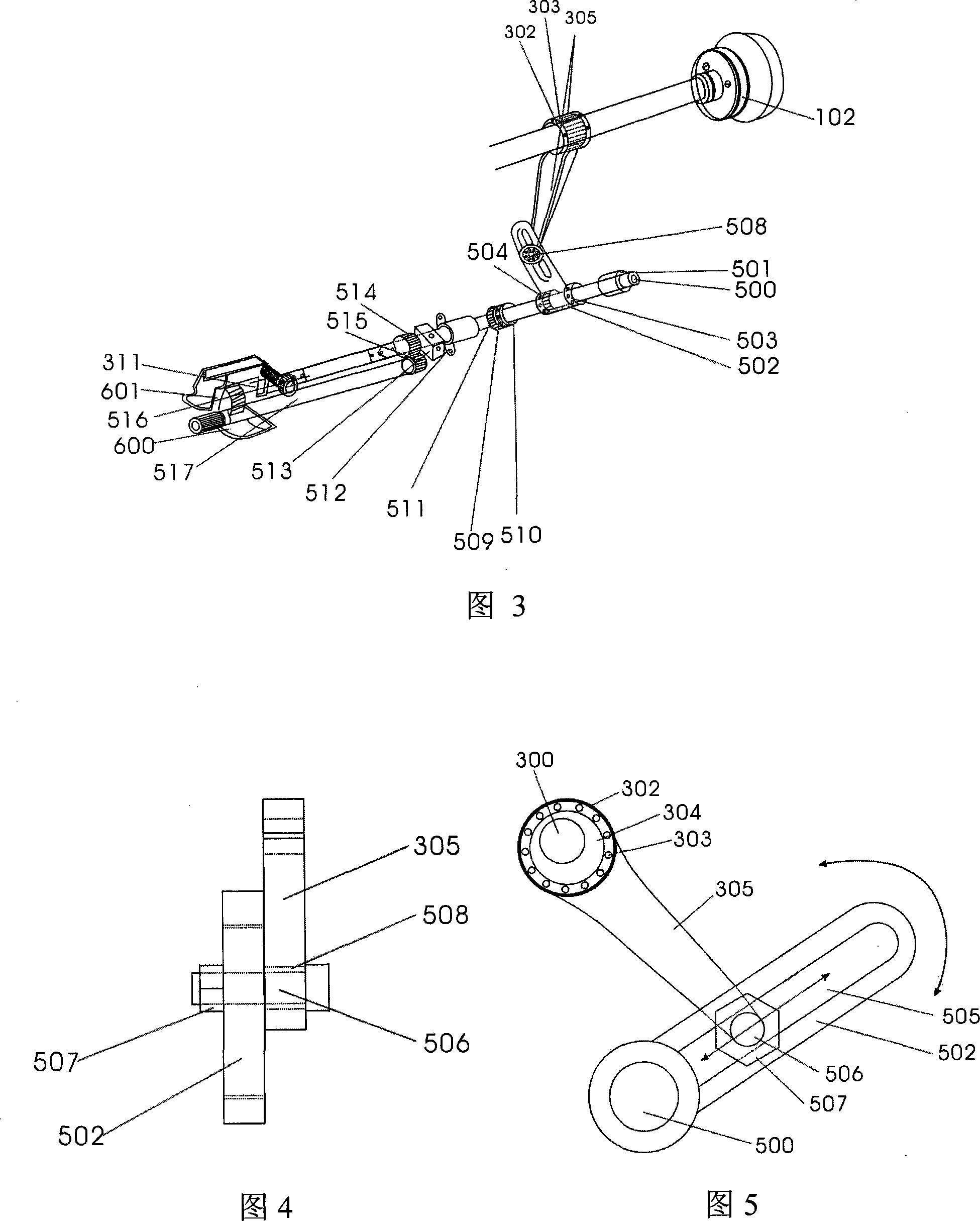

[0021] Such as figure 2 As shown, the cloth feeding tugwheel assembly of the integral head 100 of the roller foot machine is vertically provided with a vertical shaft assembly, and the two ends of the vertical shaft 200 are respectively provided with an upper vertical shaft bevel gear 201 and a vertical shaft lower bevel gear 202 . An upper shaft assembly and a lower shaft assembly are arranged in the horizontal direction. The upper shaft gear 301 of the upper shaft assembly meshes with the vertical shaft upper bevel gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com