Small-sized hot air engine

A heat engine and small-scale technology, which is applied in the direction of heat variable displacement engine devices, mechanical equipment, machines/engines, etc., can solve the problems of complex structure and high cost of use, and achieve the effects of low manufacturing cost, low cost of use and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

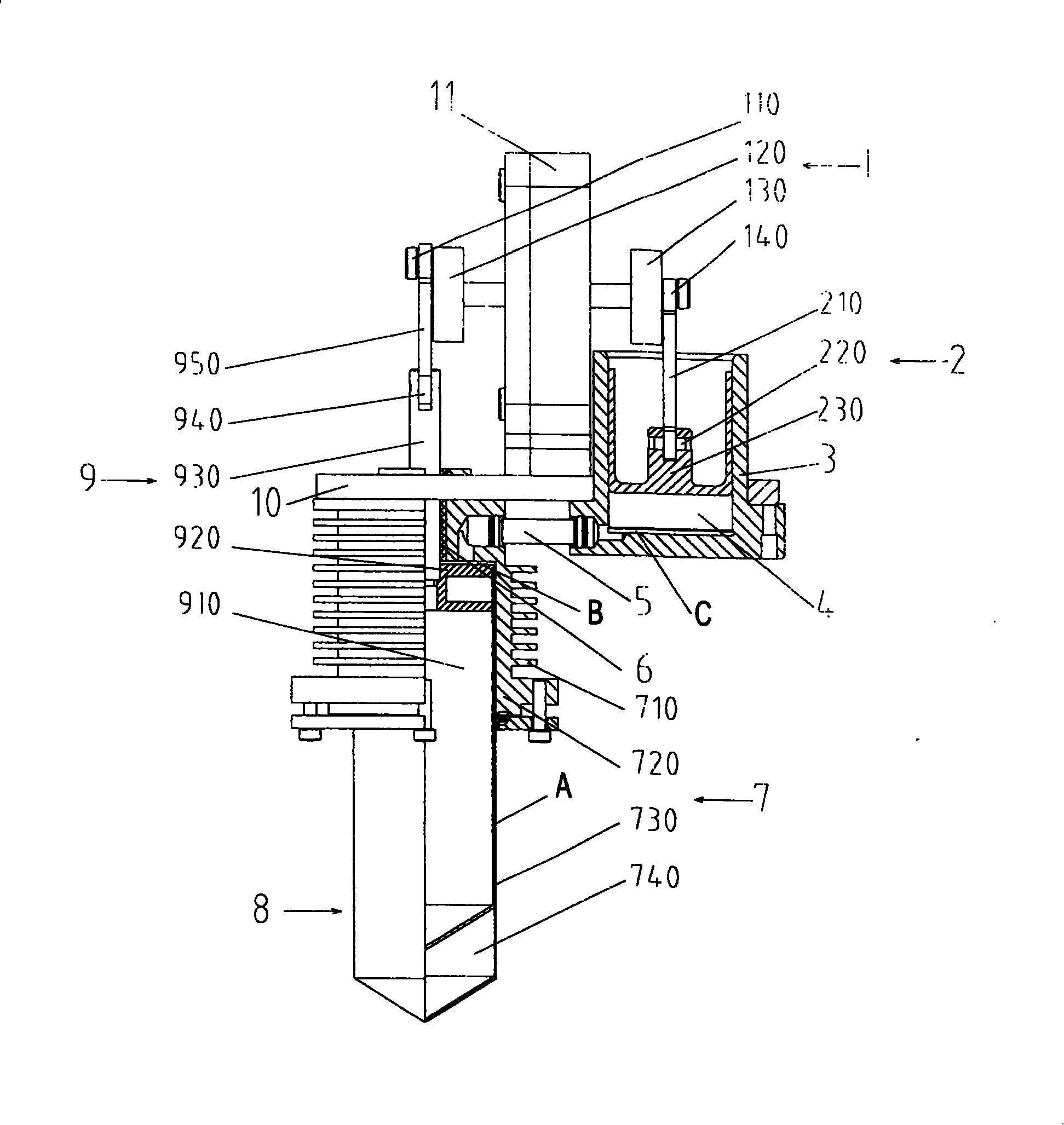

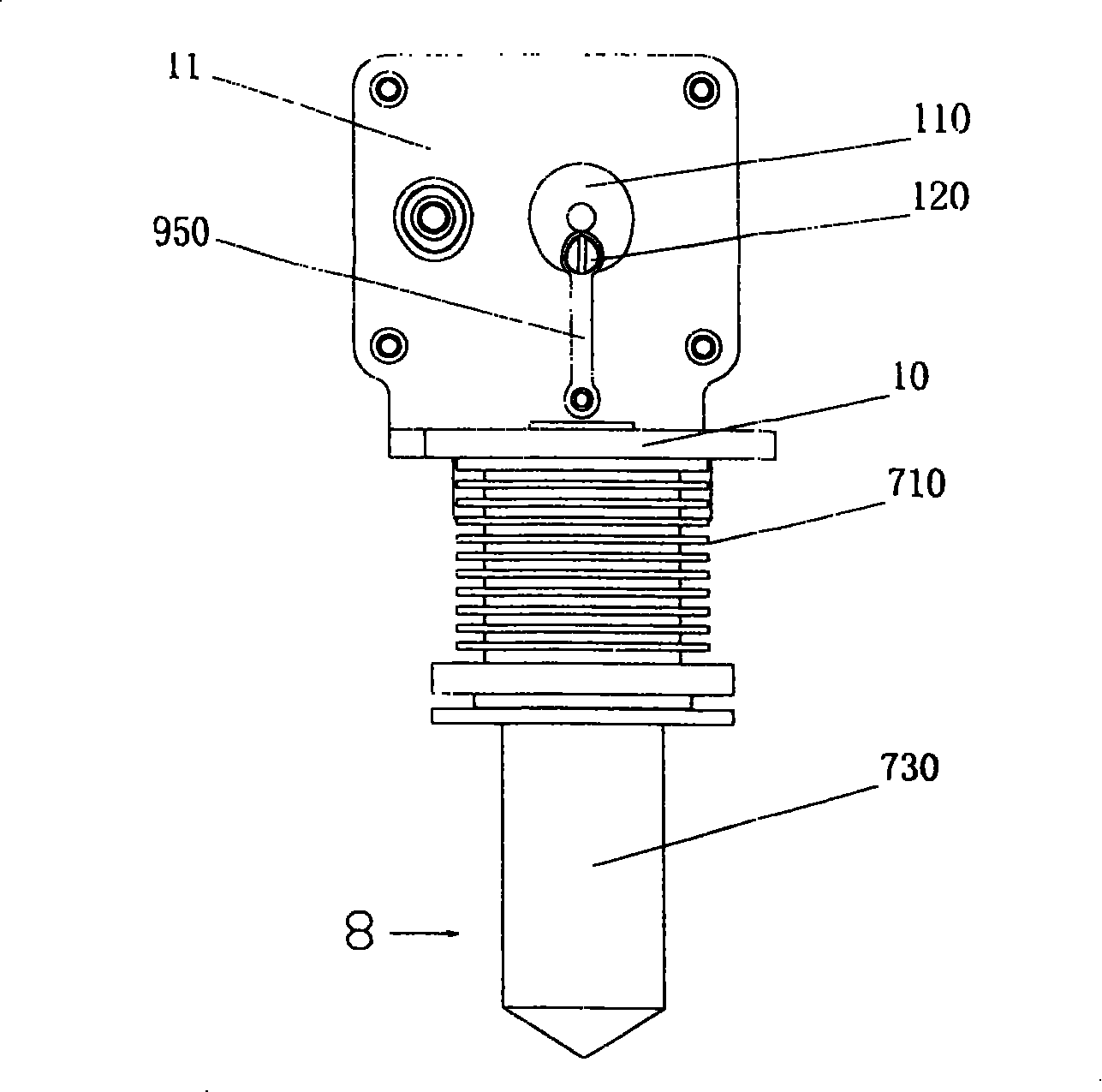

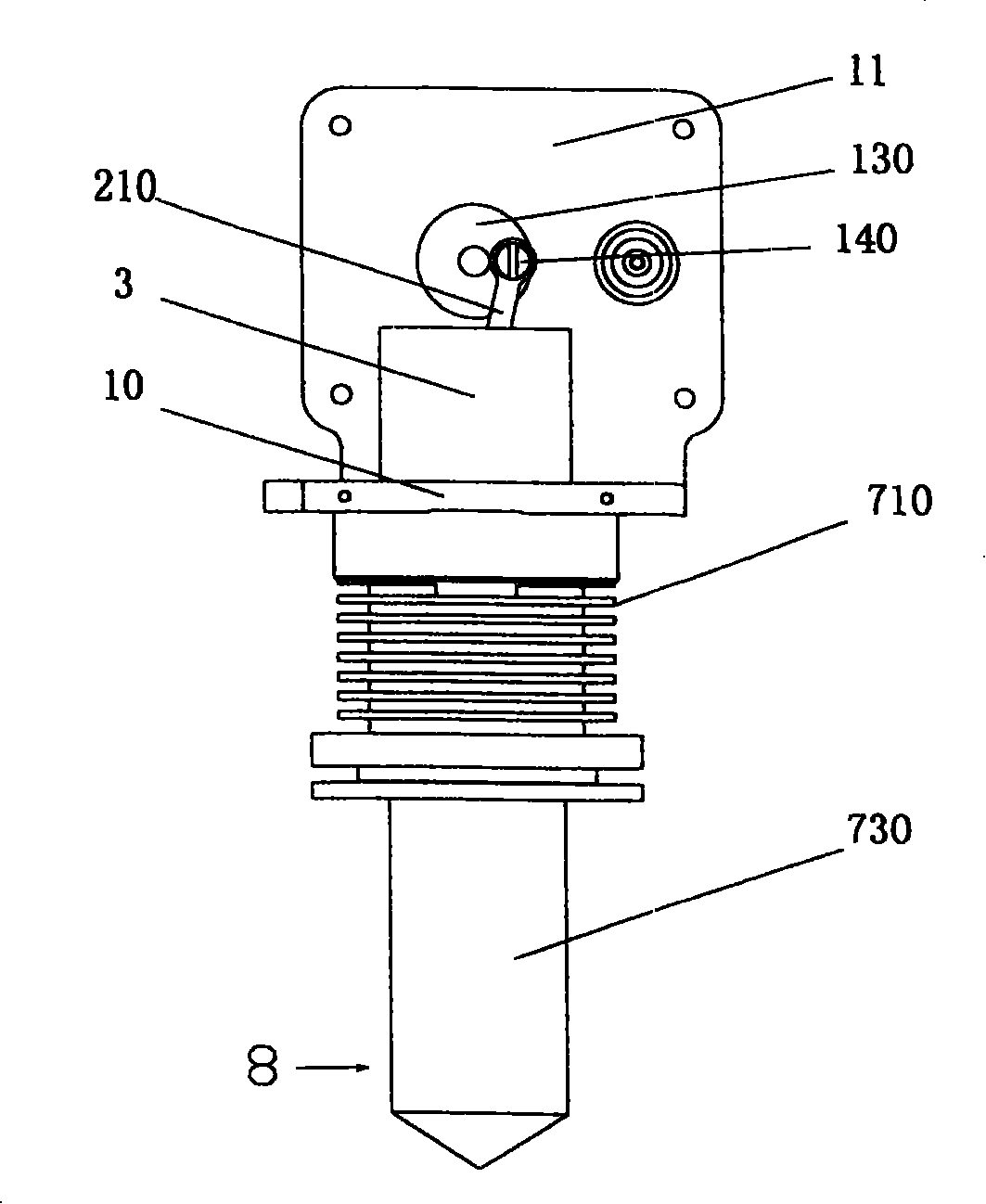

[0022] figure 1 , 2 and 3 show an embodiment of the present invention. Its structure is, comprises fuselage or machine body 10, power piston group 2, distributing piston group 9, heater 8, cooler 710, regenerator, output shaft 1 with two crank throws etc., distributing piston group 9. The power piston group 2 is rotatably connected to the output shaft 1 through the short connecting rod 950 and the long connecting rod 210 respectively, and is arranged on the same side of the output shaft 1, and the cooling valves are arranged on the outside of the gas distribution cylinder 740 from top to bottom in sequence. 710, regenerator and heater 8, the air distribution cylinder 740 and the power cylinder 4 are communicated through the air channel 5, near the top dead center of the movement of the air distribution piston group 9, a heater 8 is arranged outside the cylinder liner 730 for controlling The working fluid is heated. The hot air machine often uses hot air as the working mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com