Inservice underground pipe line on-line internal coating protection construction equipment

An underground pipeline and inner coating technology, which is applied in the direction of mechanical equipment, pipe components, pipes/pipe joints/pipe fittings, etc., can solve problems such as unavoidable, high construction costs, complicated processes and tooling equipment, etc., and achieve extended service life, The effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

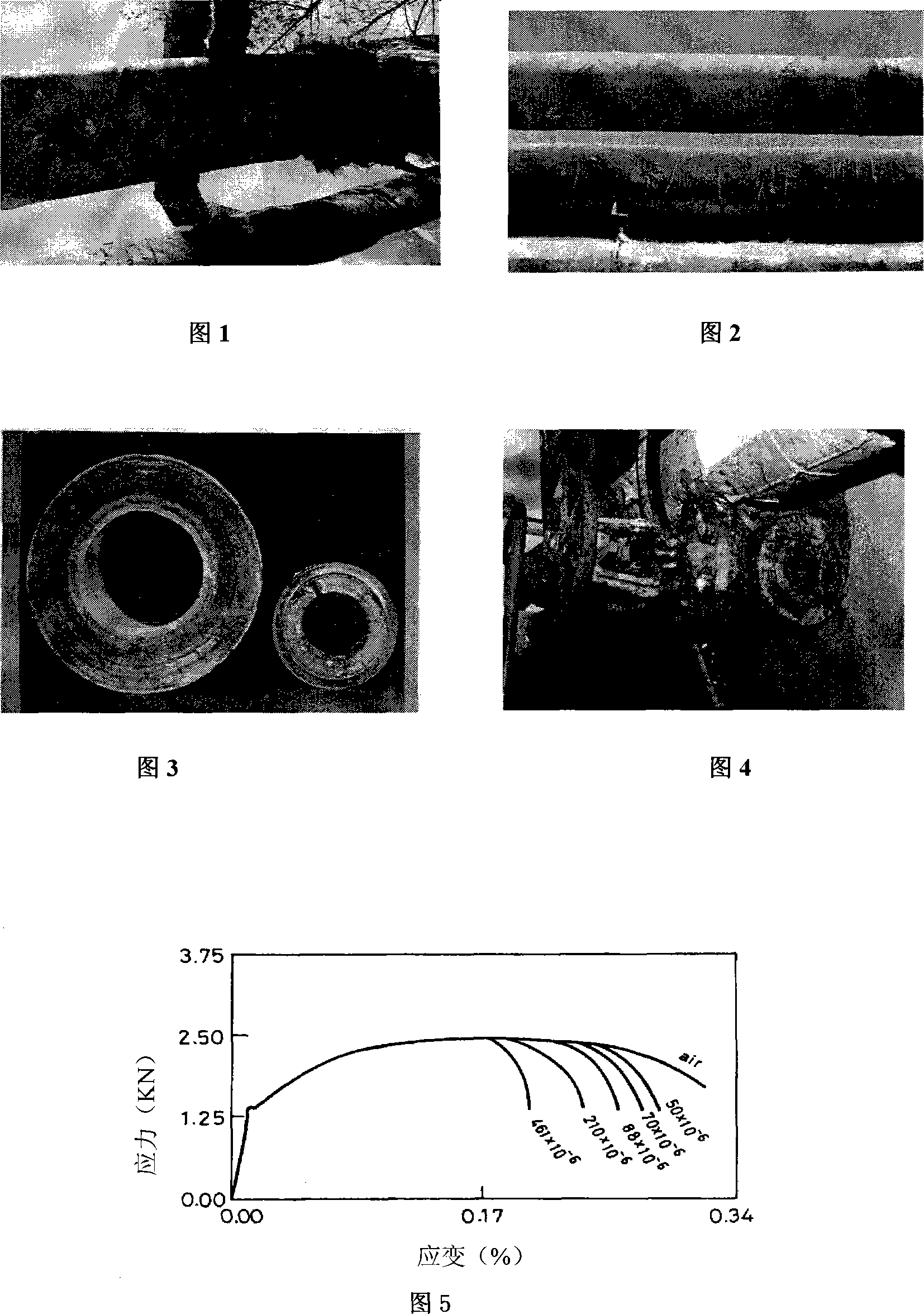

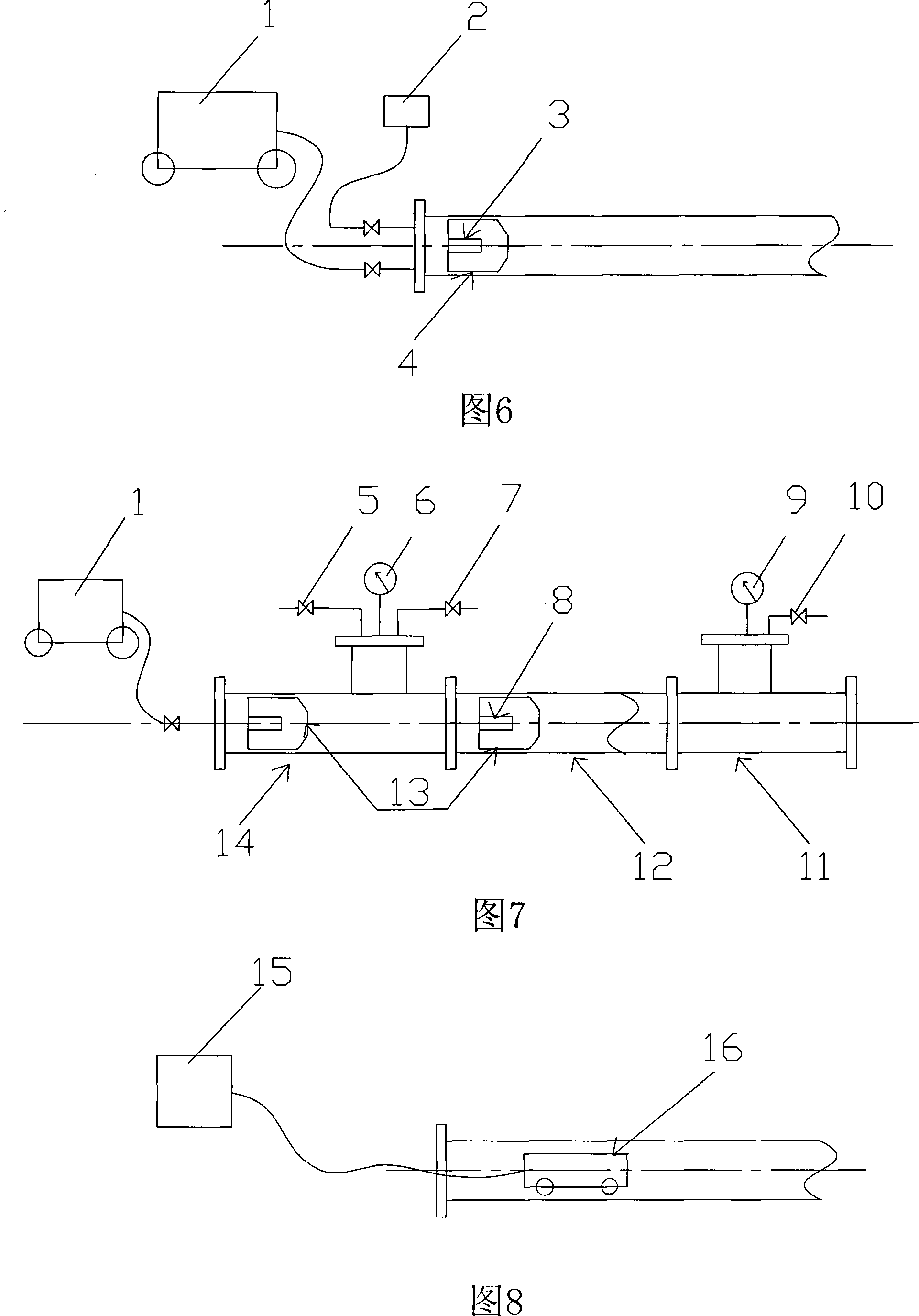

[0056]The main construction equipment and tooling for underground pipeline leak plugging repair and internal coating anticorrosion of the present invention are engineering vehicles equipped for on-site or field operations, including: pigging equipment, online internal coating equipment, internal coating quality testing equipment, etc.

[0057] As shown in Fig. 6, the schematic diagram of the pigging operation of the pipeline. Pigging equipment includes: engineering vehicle 1, pressure recorder 2, pig signal transmitter 3, PIG pig 4, engineering vehicle 1 is equipped with a generator and an air compressor, and the pipeline to be processed is connected with a pressure recorder 2. A pig signal transmitter 3 is provided on the PIG pig 4 in the pipeline to be treated.

[0058] Its working process is as follows:

[0059] (1) Use compressed air as the power to push the pig pipe pig with a cutter to remove the scale and rust in the pipeline. If necessary, it must be repeated until th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com