Water content detection sensor

A technology for detecting sensors and moisture, applied in the direction of material resistance, absorbing pads, etc., can solve problems such as poor electrodes, changes in resistance value, misoperation, etc., and achieve the effect of improving accuracy and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

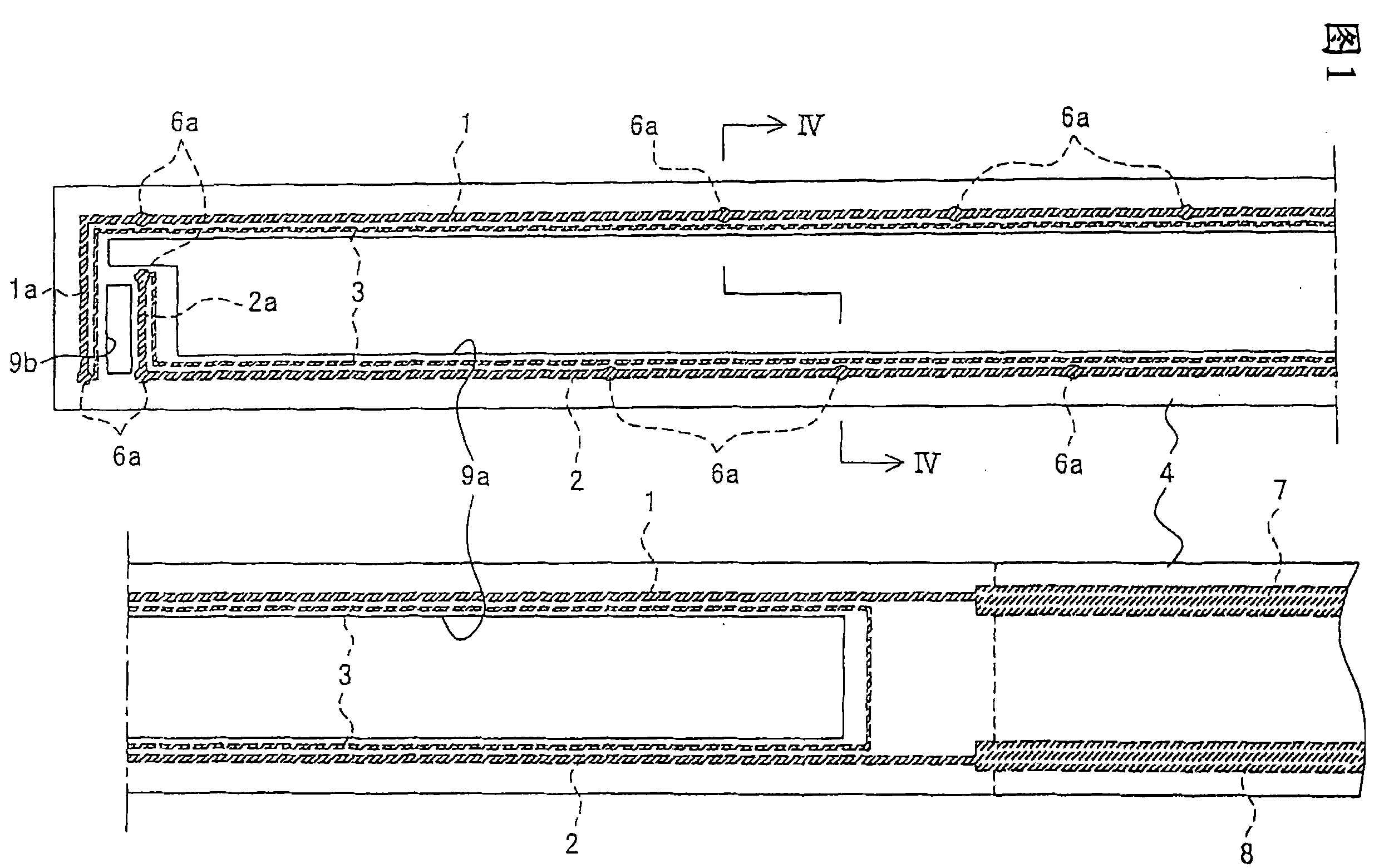

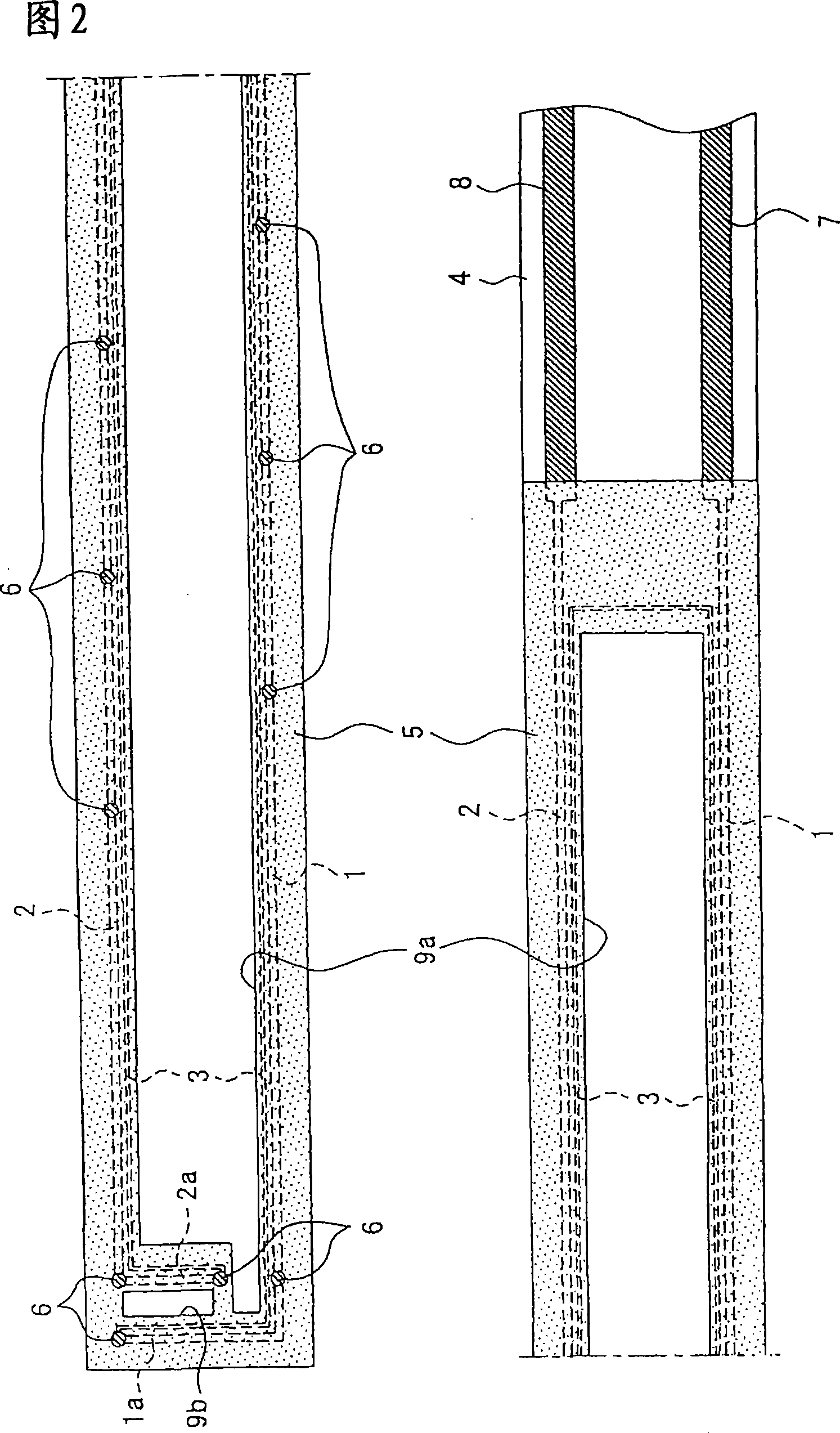

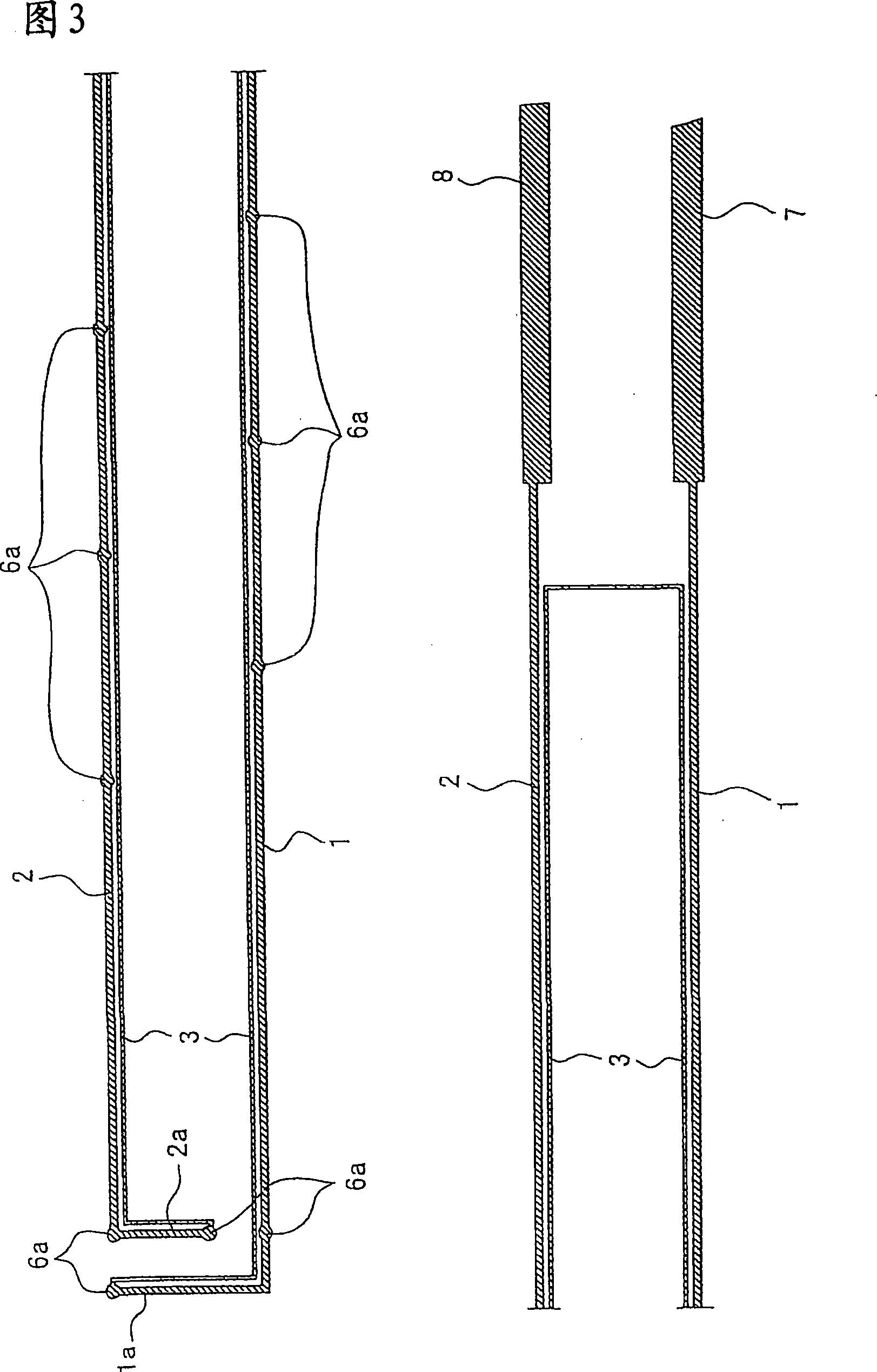

[0036] As shown in FIGS. 1 to 4 , the moisture detection sensor has a circuit portion including low-resistance wires 1 and 2 extending in parallel and a high-resistance wire 3 connecting ends of the low-resistance wires 1 and 2 . The circuit portion is sandwiched between the waterproof and insulating carrier 4 and the cover 5 , and exposure holes 6 are formed in the cover 5 through which the low-resistance lead wires 1 and 2 are exposed in multiple places.

[0037] The carrier 4 is an integral member that supports the moisture detection sensor, and is formed in a freely bending belt shape. The carrier 4 has water repellency so that moisture does not pass through, and has insulation so that electricity does not conduct. In addition, in order to easily check whether the circuit part is normal or not, it is desirable to form it transparently. The carrier 4 is made of a biaxially stretched film of polypropylene, polyethylene, polyvinyl chloride, polyester, polyamide, polyimide, p...

Embodiment approach 2

[0053] In this second embodiment, as shown in FIG. 5 , the high-resistance lead wire 10 of the circuit portion of the moisture detection sensor is formed shorter than that of the first embodiment.

[0054] In addition, the same code|symbol is used for the same part as Embodiment 1, and the overlapping description is abbreviate|omitted.

Embodiment approach 3

[0056] In this Embodiment 3, as shown in FIG. 6, the high-resistance wire 11 of the circuit portion of the moisture detection sensor is formed shorter than that of Embodiments 1 and 2, and at one end of the two low-resistance wires 1, 2 between them, extending linearly.

[0057] In addition, the same parts as those in Embodiments 1 and 2 are denoted by the same symbols, and overlapping descriptions are omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com