Finned tube type heat exchanger inner lining with foam metal

A technology of metal foam and finned tubes, which is applied in the direction of tubular elements, heat transfer modification, heat exchange equipment, etc., can solve the problems that the heat exchange area cannot be greatly increased, and the enhanced heat exchange in the tube encounters bottlenecks, etc., to achieve reduction The effect of small volume, increased cost and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

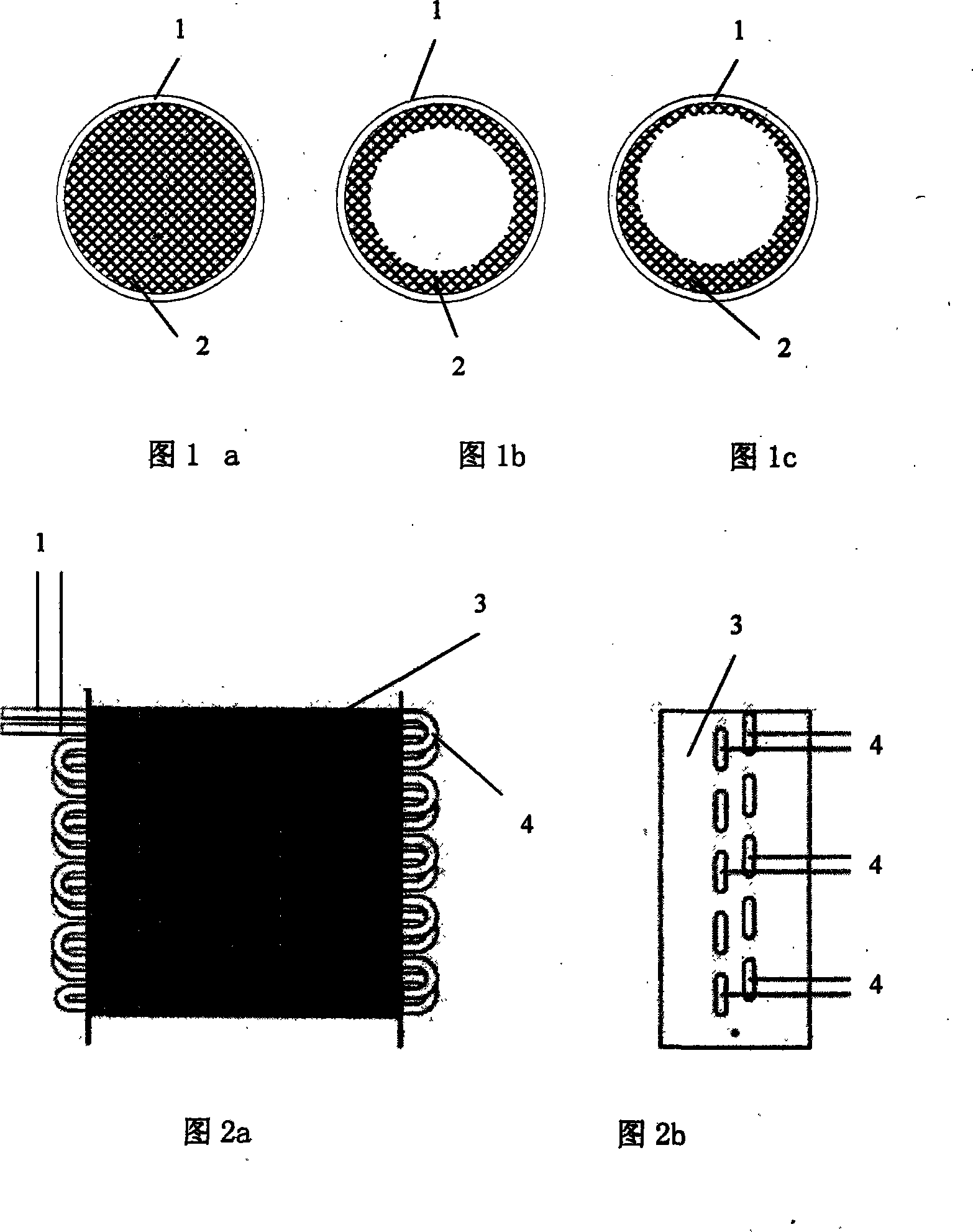

[0025] Cut the cylindrical metal foam 2 whose length is the same as that of the metal pipe 1 and whose diameter is slightly larger than the inner diameter of the metal pipe 1 (the axial section is shown in Figure 1a). Fix the metal tube 1, push the cylindrical metal foam 2 into the metal tube 1 along the axial direction of the tube, and at the same time use a wire to connect with the end of the columnar metal foam 2 entering the metal tube 1, and help overcome the problem by pulling the metal wire. The frictional resistance between the metal foam 2 and the pipe wall until the metal foam 2 is completely embedded in the metal pipe 1. Since the diameter of the columnar metal foam 2 is slightly larger than the inner diameter of the metal tube 1, the edge of the metal foam 2 will be squeezed and deformed, so as to be more tightly combined with the inner wall of the metal tube 1. Of course, other methods can also be used to fill the metal foam 2 In the metal tube 1, as long as the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Inner diameter range | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com