Multifunctional digital display dynamometer

A dynamometer and multifunctional technology, applied in the field of multifunctional digital display dynamometers, can solve problems such as unsuitable work, affecting the stability and correctness of motion, and stability effects, so as to be easy to carry and use on site, and realize replaceable performance and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The existing testing instruments can no longer meet the requirements. In order to improve the testing accuracy and control the loading speed, we invented multifunctional digital force measuring instruments with measuring ranges of 10kN, 20kN, 30kN, and 50kN.

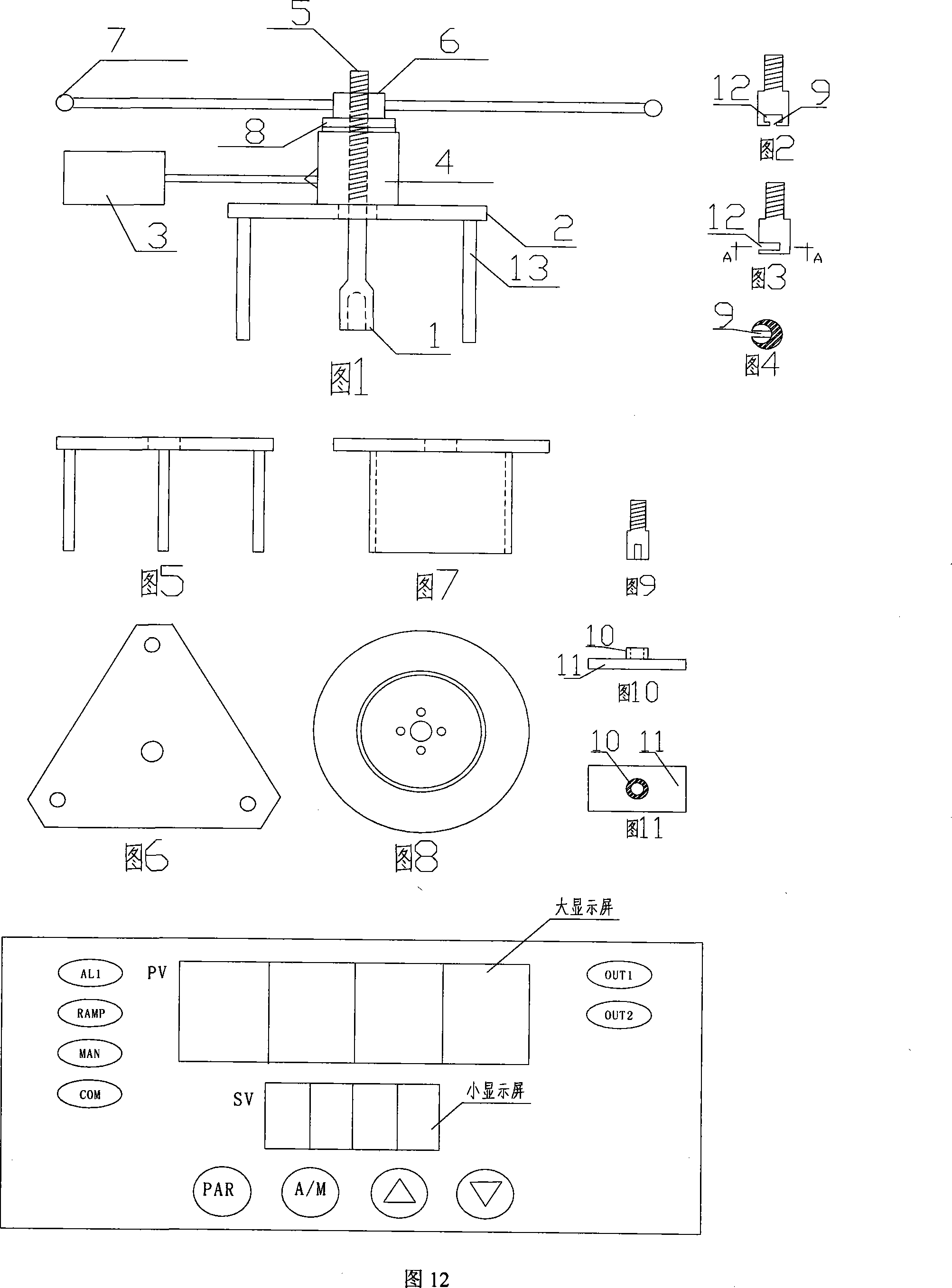

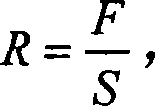

[0047] As shown in Figure 1, Figure 5-8, before testing, determine the measuring range according to the testing items, select the appropriate sensor 4 and reaction support frame 2, the sensors are divided into 1T (10kN), 2T (20kN), 5T (50kN), The reaction force support frame 2 is divided into three-point support and circular support, and the sensor 4 is installed on the reaction force support frame 2 through four positioning bolts on the platform of the reaction force support frame 2 .

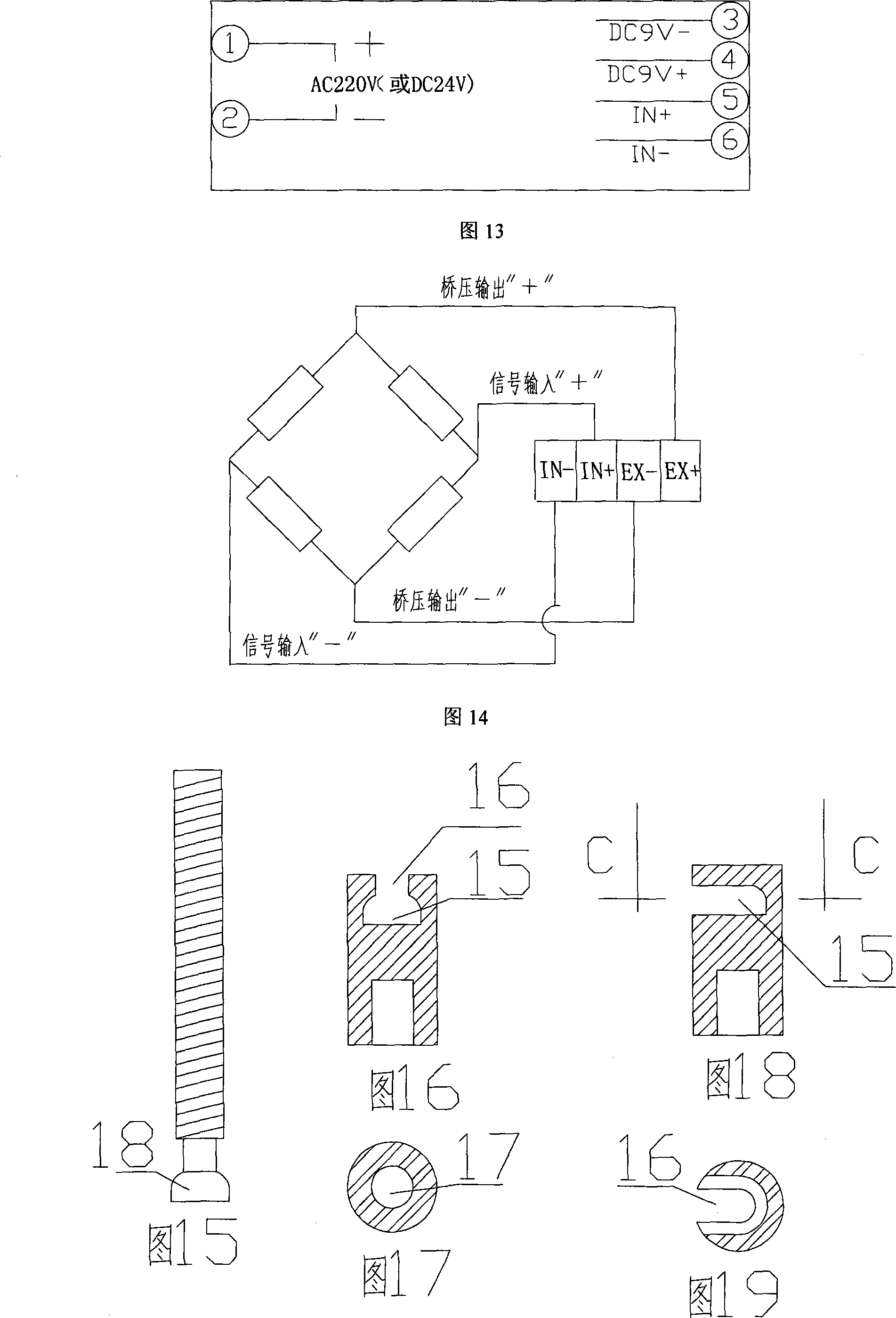

[0048] The digital display instrument of the invention is suitable for all resistance strain type load cells, and can be used in conjunction with various range sensors to measure, display and precisely control tension and pressure....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com