Test system and method for circuit board

A technology of testing system and testing method, which is applied in the direction of electronic circuit testing, measuring electricity, measuring devices, etc., can solve problems such as difficulties, low efficiency, and cumbersome circuit board testing work, and achieve the effect of rapid testing and improving testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

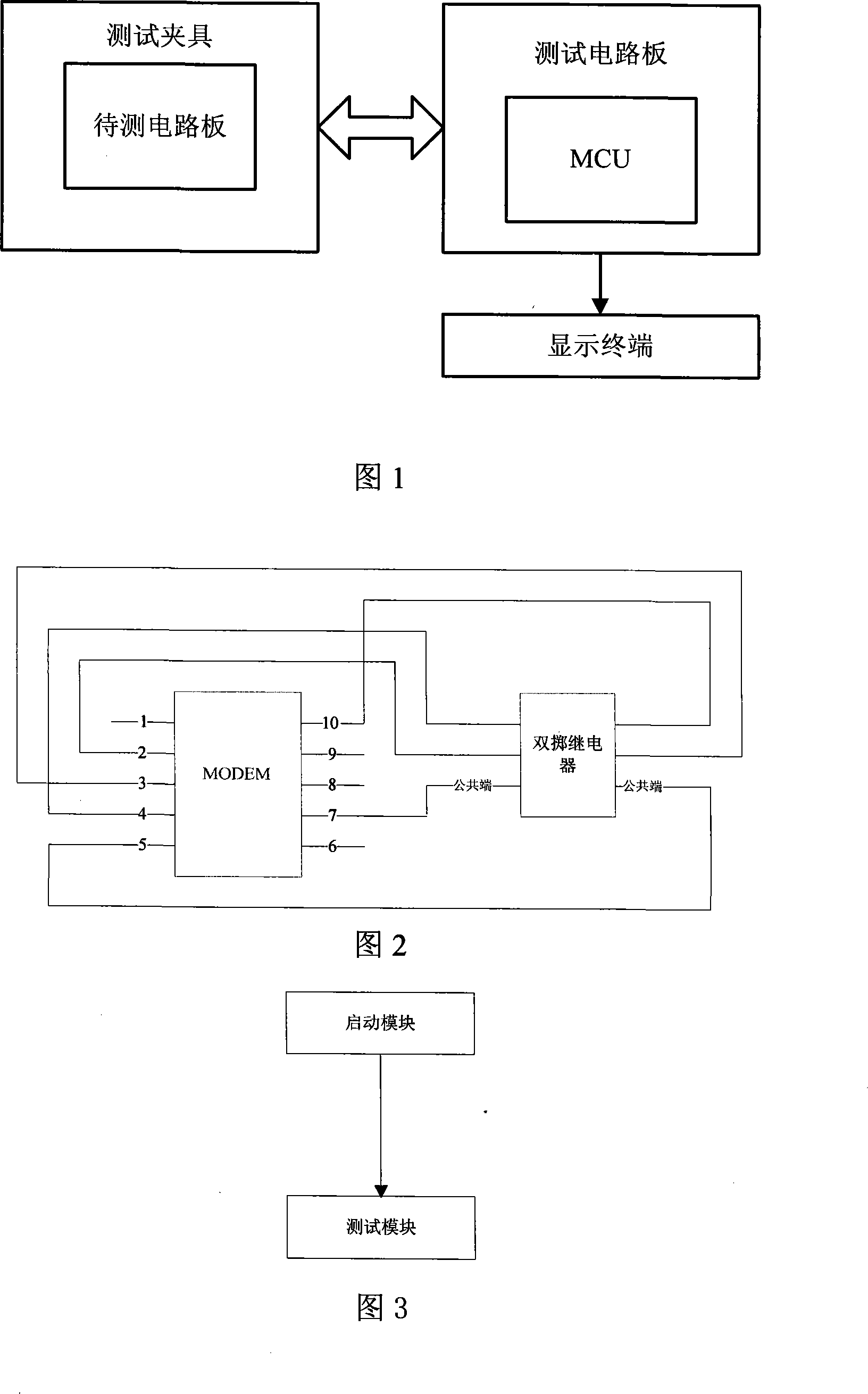

[0031] As shown in Figure 1, the present invention fixes the circuit board to be tested by a test fixture, and the test fixture includes a test seat and test pins, and the test seat is used to carry the circuit board to be tested, and the number and distribution of the test pins are based on the circuit to be tested. For example, confirm that the hardware interfaces to be tested on the circuit board to be tested include external interfaces, program download interfaces, power interfaces, and reset interfaces. Then customize the test fixture so that the test pins correspond to the pins of each interface one by one and can be fully contacted during the test, so that the damage of the interface pins can be avoided. The test fixture can also add ammeters, power switches, buttons, indicator lights, etc. according to its own needs.

[0032]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com