Multifeed mould temperature control system of high light weld mark free shooting technique

A technology of temperature control system and multi-point mould, which is applied in the field of injection molding of material processing disciplines, can solve the problems of only one injection molding machine being controlled and the temperature controller is expensive, and achieve high mold temperature control accuracy, heating and cooling The effect of large range and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

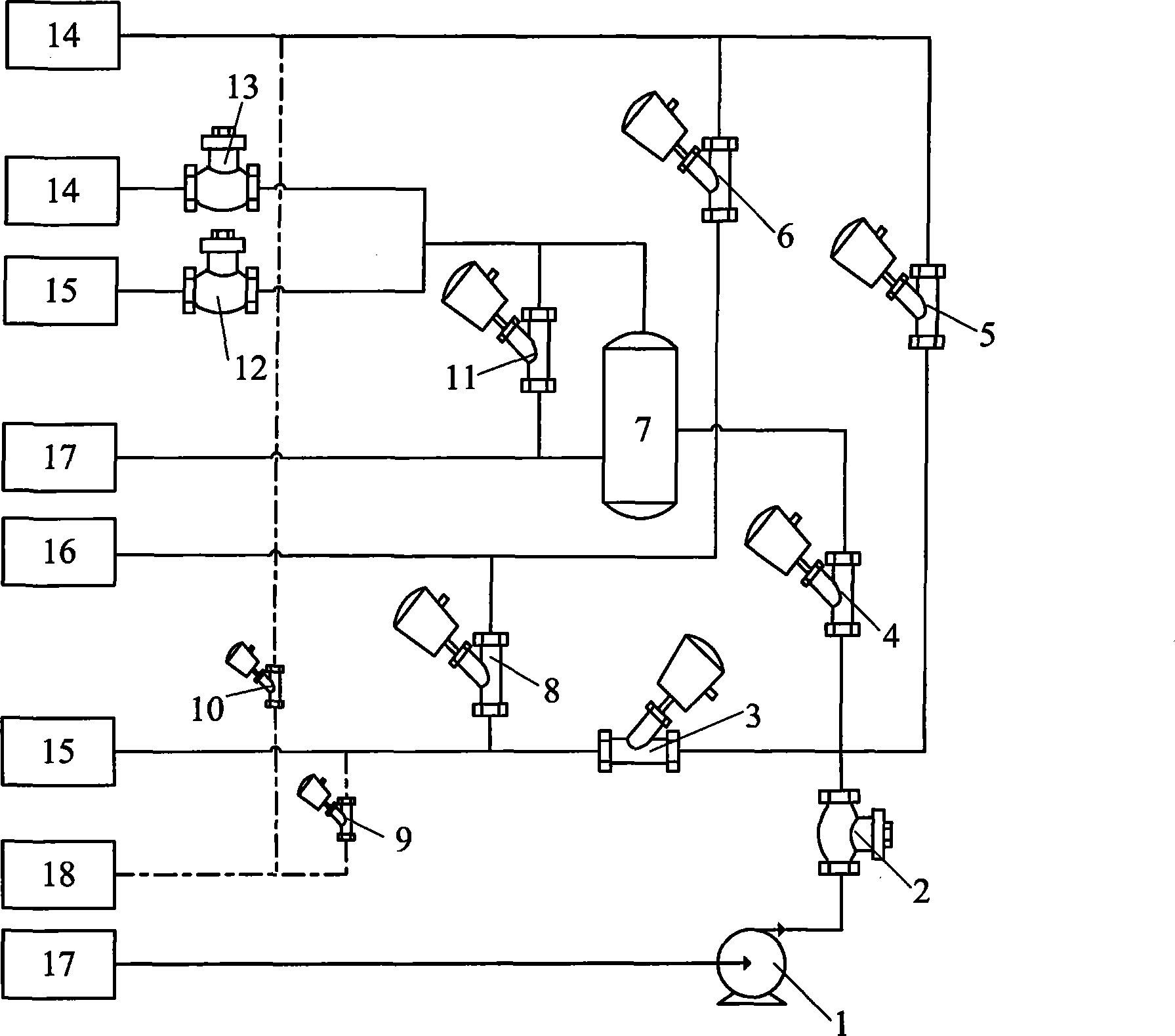

[0018] As shown in the accompanying drawings, the multi-point mold temperature control system of the present invention mainly includes a water pump 1, a control unit (not shown in the figure), various pipelines (solid lines in the figure represent cooling water and steam pipelines, dotted lines Indicates compressed air pipeline), various control valves and mixer 7, etc. The first mold 14 and the second mold 15 are equipped with temperature sensors, and the pipelines connecting the inlet and outlet of the first mold 14 and the second mold 15 are respectively equipped with temperature sensors, and each temperature sensor and control valve are connected to the control unit through communication cables. The control unit is connected with the touch screen through a communication cable.

[0019] The high-temperature and high-pressure steam generated by the boiler 16 enters the No. 1 mold 14 and the No. 2 mold 15 through two branches of the steam pipeline, one path enters the inlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com