Cartridge for solid imaging apparatus and method

A technology of imaging equipment and barrel, applied in the field of solid imaging equipment, can solve the problems of curing resin block pollution, lowering efficiency of alignment steps, and increasing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The present invention is best understood by reference to the specific embodiments shown in the drawings and in the variations described below. While the invention has thus been described, it should be understood that the invention is not limited to the embodiments shown in the drawings. On the contrary, the invention includes all alternatives, modifications and equivalents which may be included within the scope and spirit of the invention as defined by the appended claims.

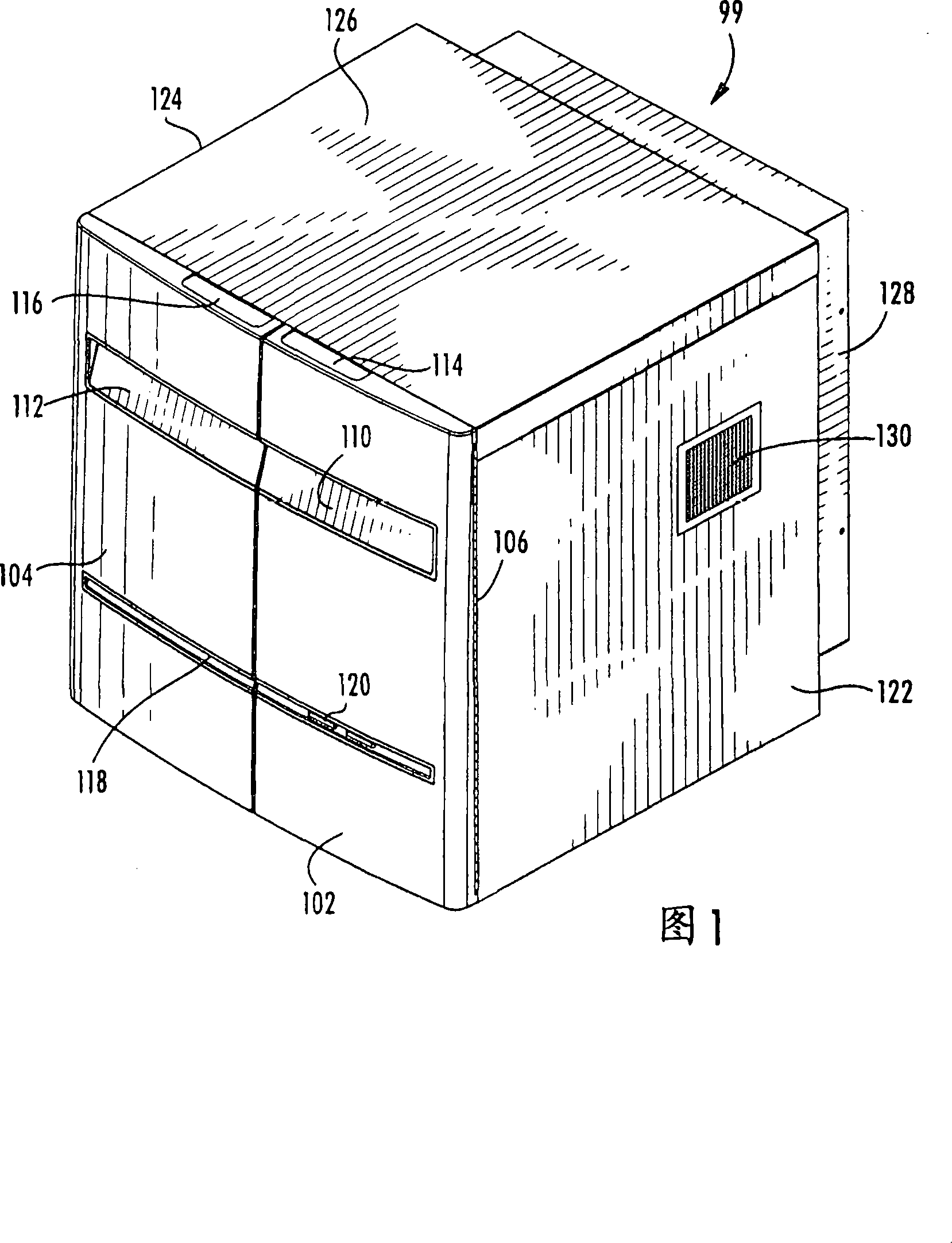

[0094] FIG. 1 shows generally at 99 in perspective view one embodiment of a housing for the table top modeler of the present invention. Housing 99 includes a right hand hinged door 102 and a left hand hinged door 104 . The hinges for the door 102 can be seen at 106 . The door 102 is provided with handles 110 and 114 on the front and top respectively, and the door 104 is provided with handles 112 and 116 on the front and top respectively. It should be appreciated that many such arrangements may be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com