Elastomer and organic rigidity particle coordination plasticizing polystyrene and preparation method thereof

A technology of rigid particles and polystyrene, which is applied in the field of toughened polystyrene and its preparation, and can solve the problems of rigidity, strength, heat distortion temperature reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

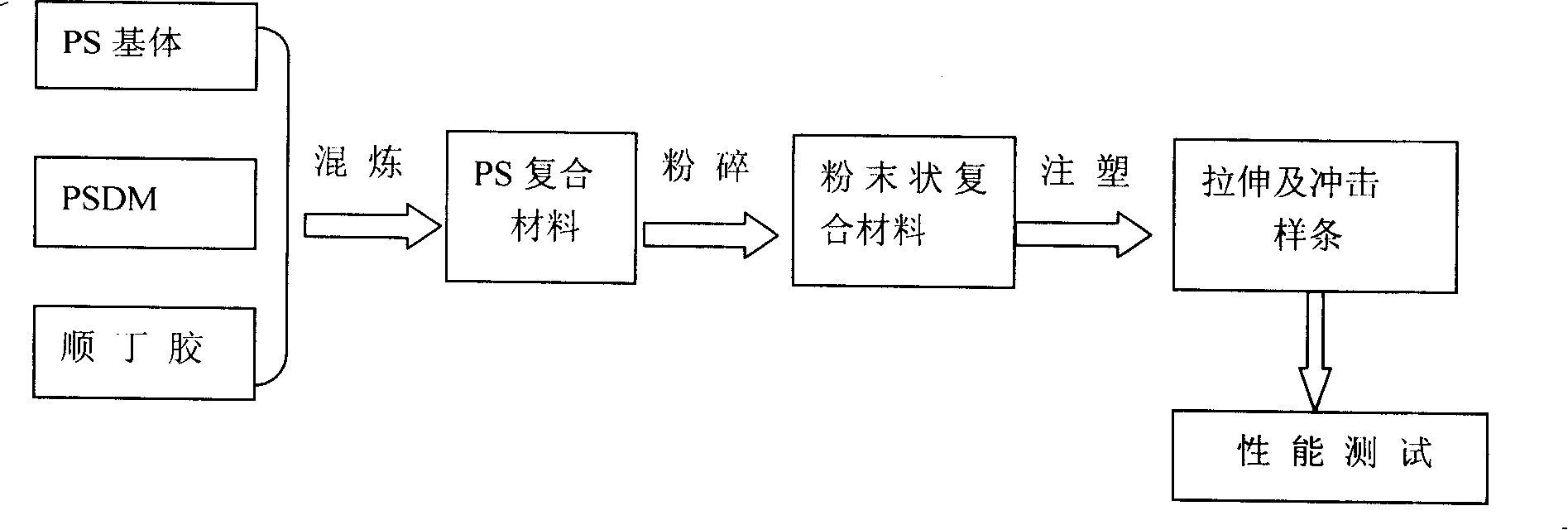

Method used

Image

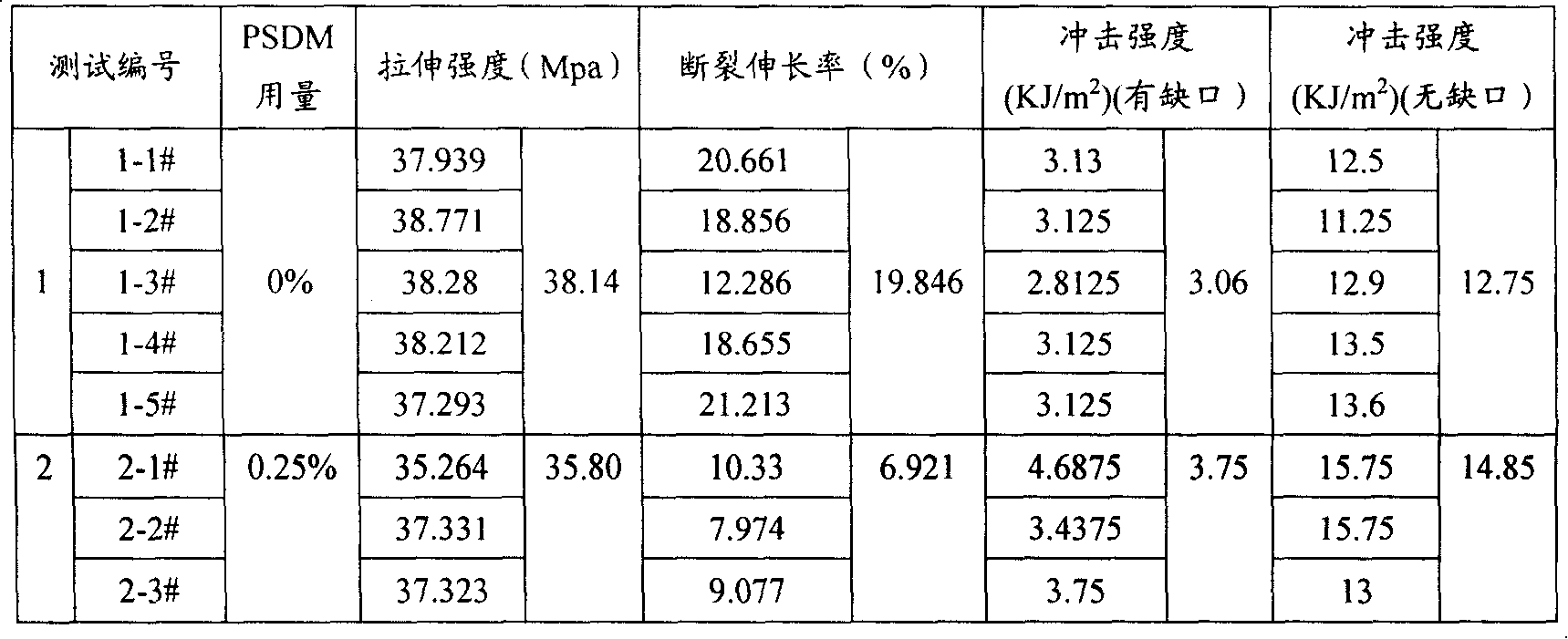

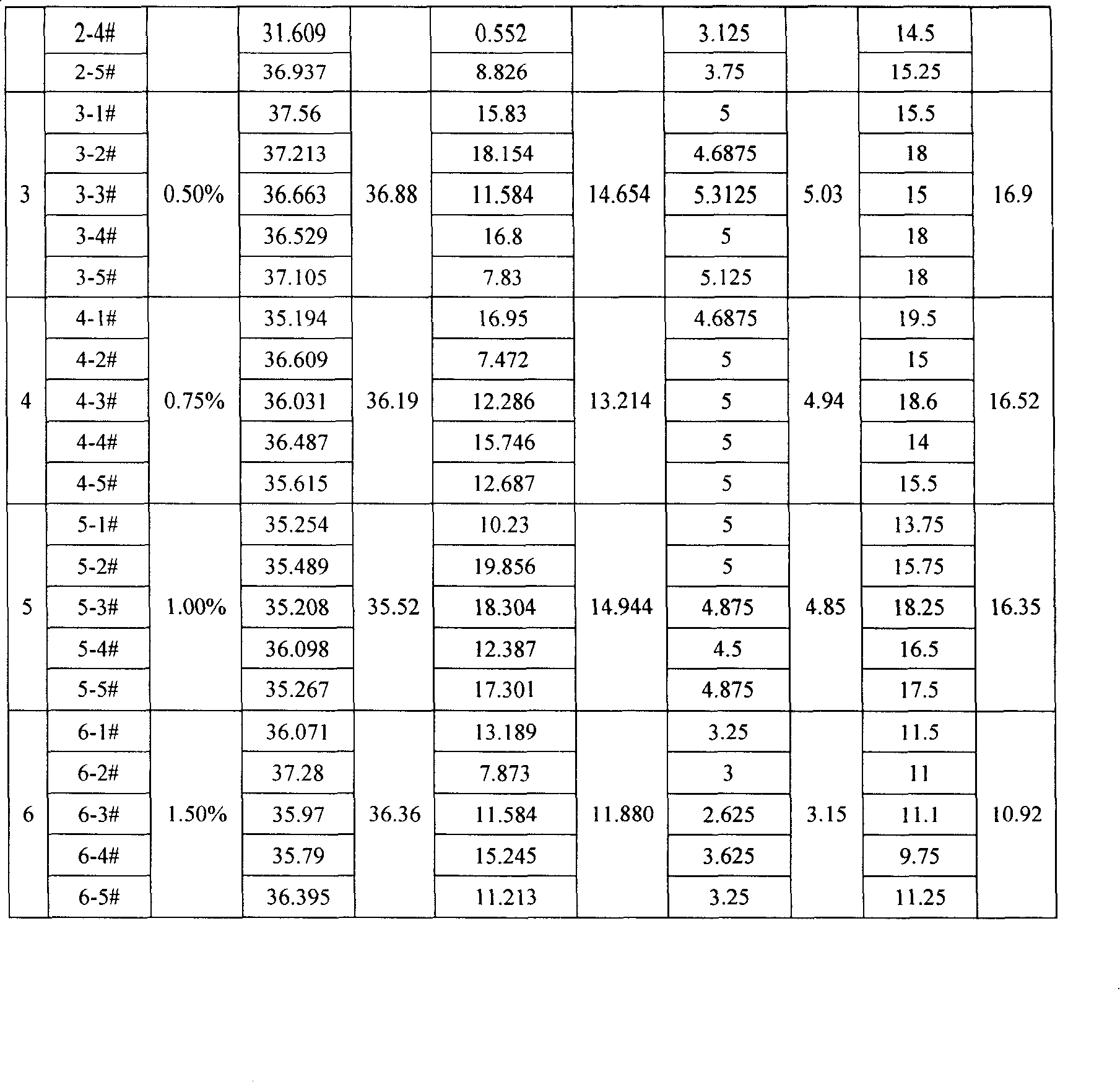

Examples

Embodiment Construction

[0021] The following examples are only to further illustrate the present invention in detail, and the present invention should not be limited to the specific and express contents of the following experimental examples without violating the gist of the present invention.

[0022] The raw materials used in the embodiment are as follows:

[0023] Styrene Shandong Qilu Petrochemical Co., Ltd.

[0024] Methyl methacrylate Shandong Qilu Petrochemical Co., Ltd.

[0025] Industrial PS Shandong Qilu Petrochemical Co., Ltd.

[0026] Butadiene Rubber (BR9000) Shandong Qilu Petrochemical Co., Ltd.

[0027] Sodium oleate analytically pure Shanghai Reagent No. 1 Factory

[0028] Divinylbenzene (DVB) Shanghai Reagent No. 1 Factory

[0029] Sodium persulfate (KPS) Shanghai Reagent No. 1 Factory

[0030] NaHCO 3 Analytical grade Beijing Chemical Reagent Company

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com