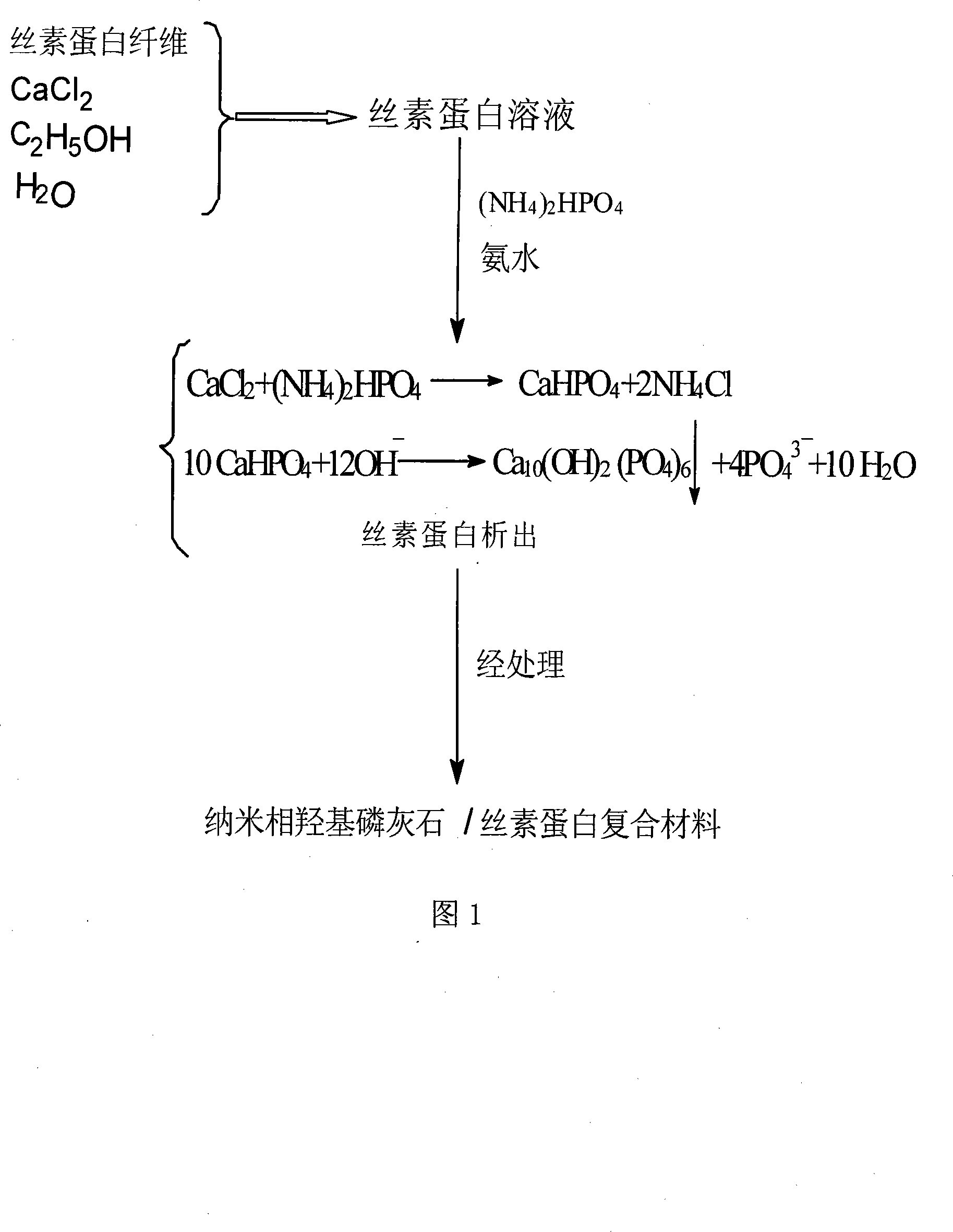

Method for preparing nano-phase hydroxyapatite/fimbrin composite material

A technology of phase hydroxyapatite and silk fibroin, which is applied in the field of preparation of nanophase hydroxyapatite/silk fibroin composite materials, can solve the problems of salt discharge, time consumption, water consumption, etc., and achieve low equipment requirements, The effect of compounding is sufficient and good, and the preparation process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The fully degummed silk fibroin fiber of 2.78g is dissolved in 27.68g CaCl 2 , 35.98g C 2 h 5 OH, 28.60g H 2 In the ternary system solvent composed of O, stir and dissolve at 75±2°C, and obtain a light yellow liquid after 0.5h; put the obtained light yellow liquid in a 1L three-neck round bottom flask, and then put the flask into In the constant temperature water bath, install a stirrer, a normal pressure dropping funnel and a pH indicator; weigh (NH 4 )HPO 4 19.80g, dissolved in 500ml of water, adjust the pH value to 10.5 with ammonia water to obtain a diammonium hydrogen phosphate solution; start the stirrer, then evenly drop the obtained diammonium hydrogen phosphate solution at a speed of 2.4ml / min, compound reaction 3.5 h, the temperature in the first 2 hours of the composite reaction is controlled at 30°C, and the temperature in the last 0.5h is controlled at 60°C; after the reaction is completed, after vacuum filtration, washing, infrared drying, and grinding...

Embodiment 2

[0030] The fully degummed silk fiber of 4.41g is dissolved in 27.68g CaCl 2 , 35.98g C 2 h 5 OH, 28.60gH 2 In the ternary system solvent composed of O, stir and dissolve at 72±2°C, and obtain a light yellow liquid after 0.5h; put the obtained light yellow liquid in a 1L three-neck round bottom flask, and then put the flask into In the constant temperature water bath, install a stirrer, a normal pressure dropping funnel and a pH indicator; weigh (NH 4 )HPO 4 19.80g, dissolve in 500ml of water, adjust the pH value to 11 with ammonia water, and obtain the diammonium hydrogen phosphate solution; start the stirrer, then add the obtained diammonium hydrogen phosphate solution evenly at a speed of 2.4ml / min, compound reaction for 4h , the temperature is controlled at 30°C for the first 3h of the composite reaction, and 60°C for the next 1h; after the reaction is completed, the composite material in powder form can be obtained after vacuum filtration, washing, infrared drying, and...

Embodiment 3

[0037] The difference between this embodiment and embodiment 2 is that the added amount of silk fibroin fiber is 6.25g. Remaining with embodiment 2.

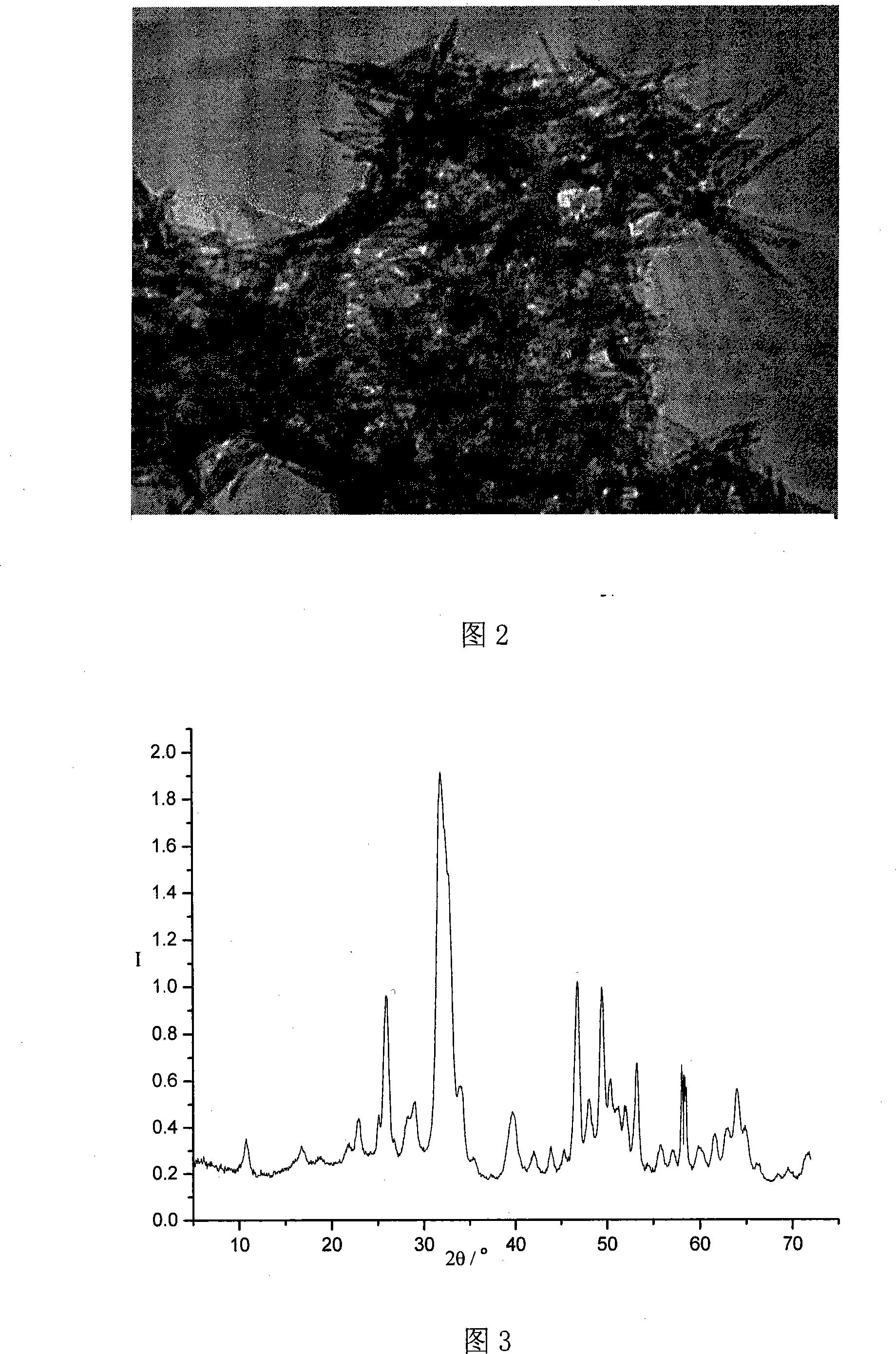

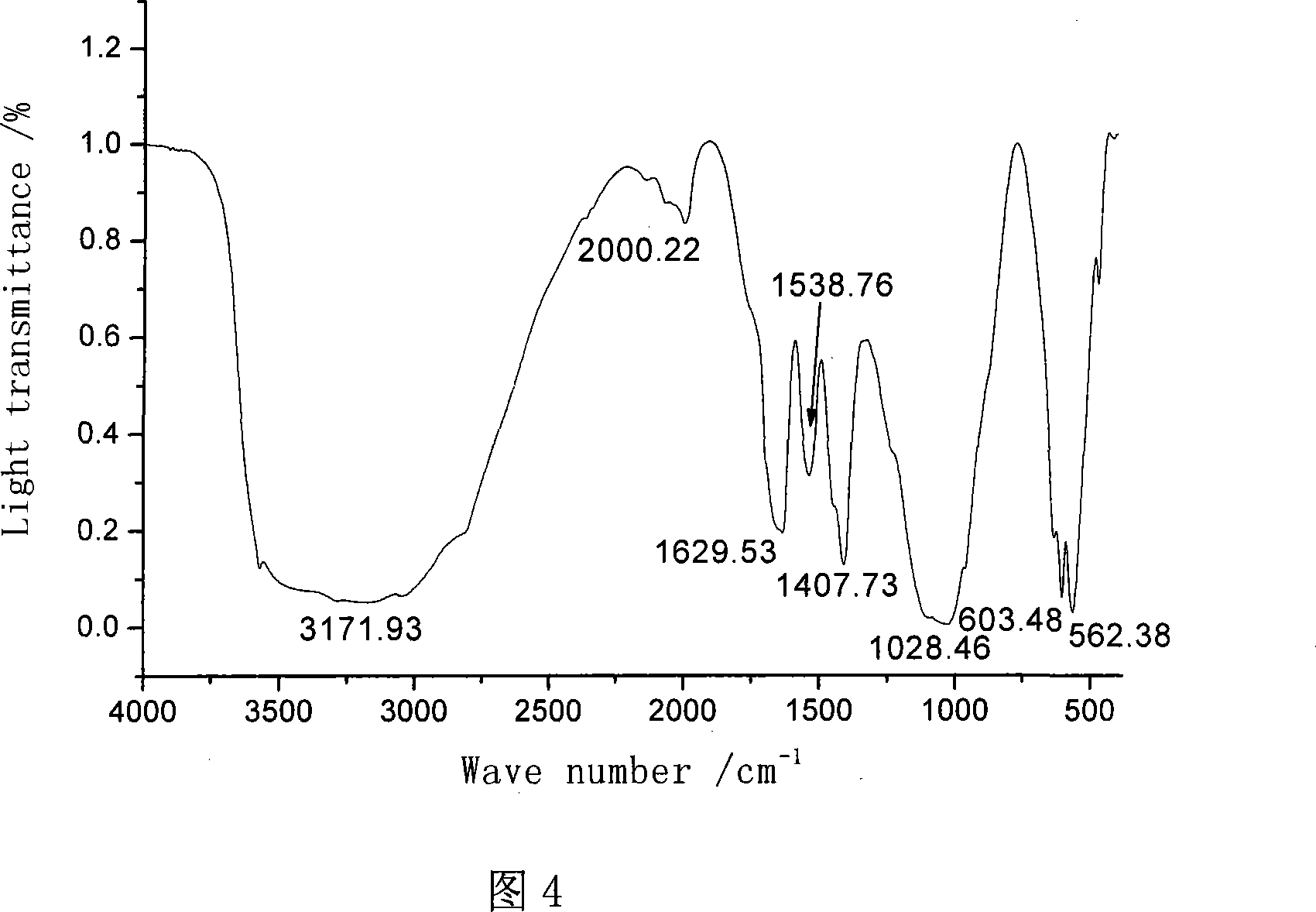

[0038] The composite material that this implementation obtains has the following characteristics after being identical with the detection of embodiment 1:

[0039] The calcium-phosphorus ratio is 1.6698, which is consistent with the calcium-phosphorus ratio in standard hydroxyapatite;

[0040] The internal two-phase composite is uniform and good, with a network structure, needle-shaped or columnar grains; the grain size is less than 50nm, and belongs to the hexagonal crystal system, and the unit cell parameters are a=b=9.0319×10 -10 m, c=7.0148×10 -10 m, the average grain size along the c-axis direction is 227.7282×10 -10 m;

[0041] Contains the respective functional groups of hydroxyapatite and silk fibroin, and does not contain new chemical functional groups;

[0042] The silk fibroin content in the composite was 20% (w / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com