Hollow silencing pipeline and its molding process and equipment

A molding equipment and silencing technology, applied in mechanical equipment, objects with hollow walls, pipes, etc., can solve the problems of poor pipeline flow capacity, noise pollution in the surrounding environment, high price, etc., to achieve strong impact resistance and ensure good health. , The effect of good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

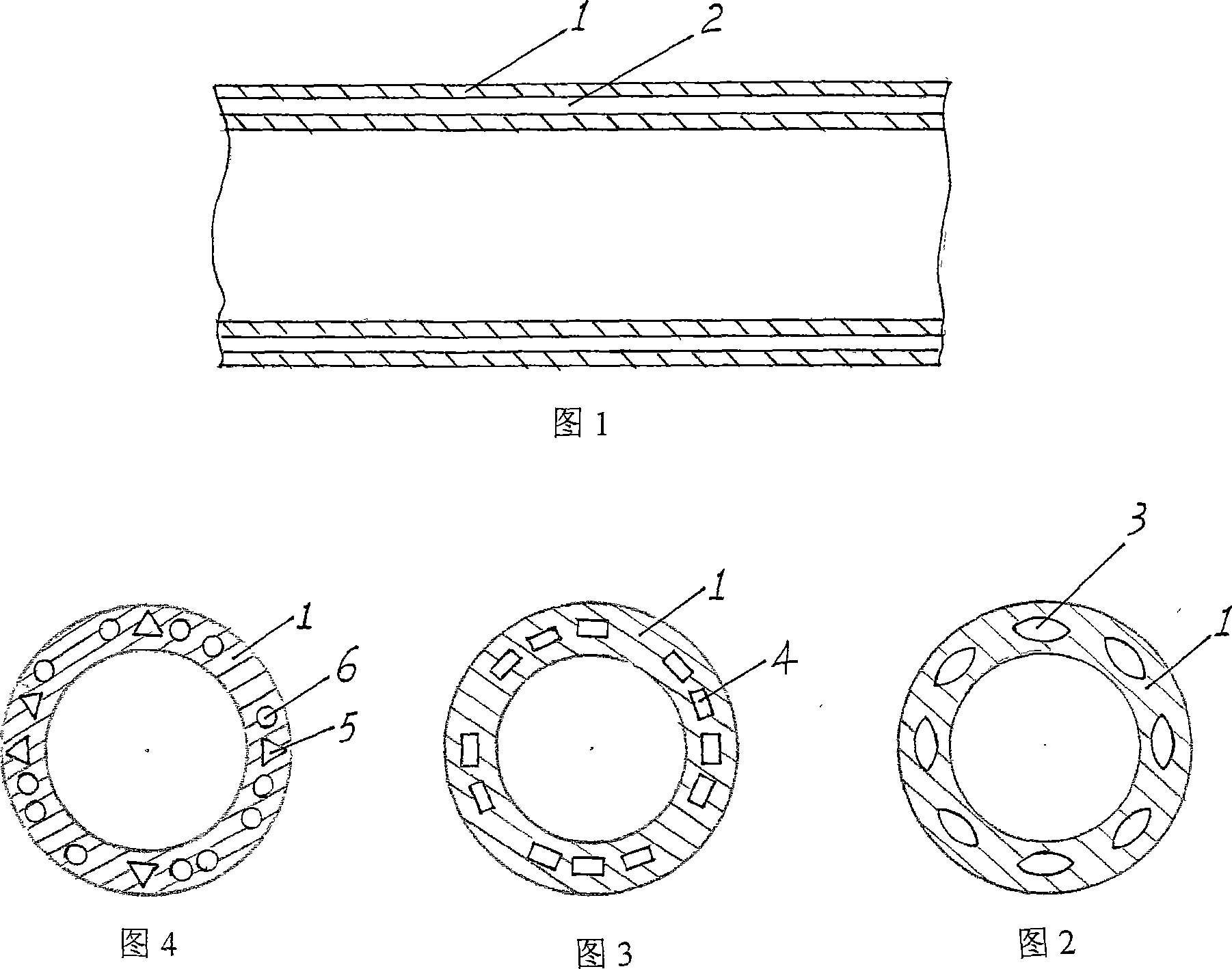

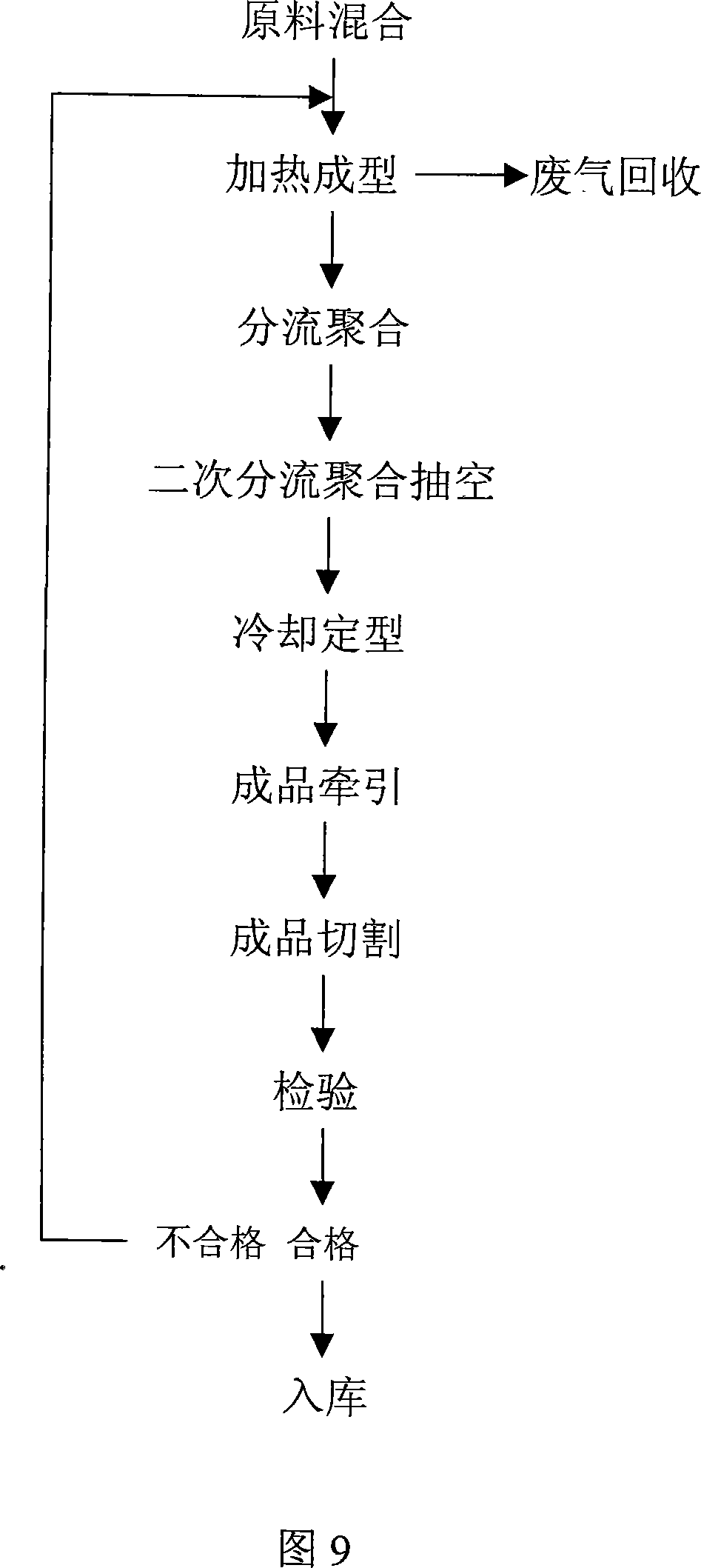

[0035] The molding process of the hollow sound-absorbing pipe provided by the present invention comprises the following steps:

[0036] 1. Mixing of raw materials: fully mix the required raw materials according to the existing formula;

[0037] 2. Heat forming:

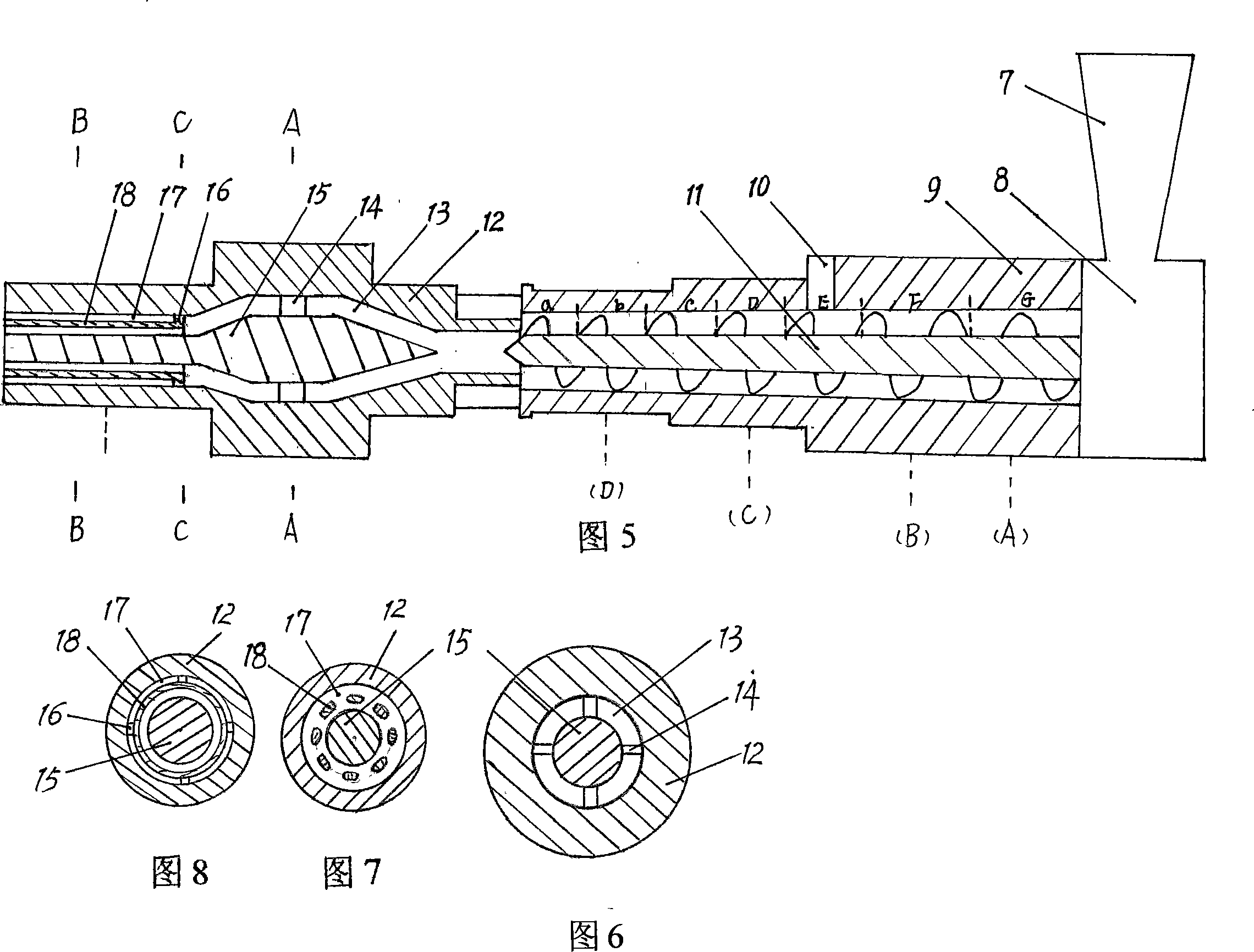

[0038] A. After feeding the mixed material into the conical twin-screw shown in Figure 5, under the condition that the screw rotation speed is 20 rpm, it is passed through in turn: the first zone (A) 185 ° C, the second zone (B) 175 ℃, zone 3 (C) 170°C, zone 4 (D) 160°C, heating and extruding for 10 minutes, then stop heating in zone 3 and zone 4, and maintain plasticization by the heat generated by the shear stress of the conical twin-screw 11 temperature, to reduce power consumption, while heating the exhaust gas produced during the extrusion process, through the exhaust through hole 10 on the conical twin-screw and the connecting pipe, it is sent to the exhaust gas recovery device for processing and recovery, and ...

Embodiment 2

[0045] The molding process of the hollow sound-absorbing pipeline provided by the present invention, its thermoforming is:

[0046]A. After feeding the mixed material into the conical twin-screw shown in Figure 5, under the condition that the screw rotation speed is 40 rpm, it passes through in turn: the first zone (A) 195 ° C, the second zone (B) 185 ℃, zone 3 (C) 180°C, zone 4 (D) 170°C, heating and extruding for 5 minutes, then stop heating in zone 3 and zone 4, and maintain plasticization by the heat generated by the shear stress of the conical twin-screw 11 temperature, to reduce power consumption, while heating the exhaust gas produced during the extrusion process, through the exhaust through hole 10 on the conical twin-screw and the connecting pipe, it is sent to the exhaust gas recovery device for processing and recovery, and then emptied;

[0047] B. The raw material heated and plasticized by the conical twin-screw directly enters the forming mold, firstly conducts a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com