Cylinder type hologram manufacture method, manufacture device and manufactured hologram

A manufacturing method and a technology for manufacturing devices, which are applied in the field of holography, can solve the problems of limited application range, waste of laser energy, difficulty in control, etc., and achieve the effects of cost reduction and wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

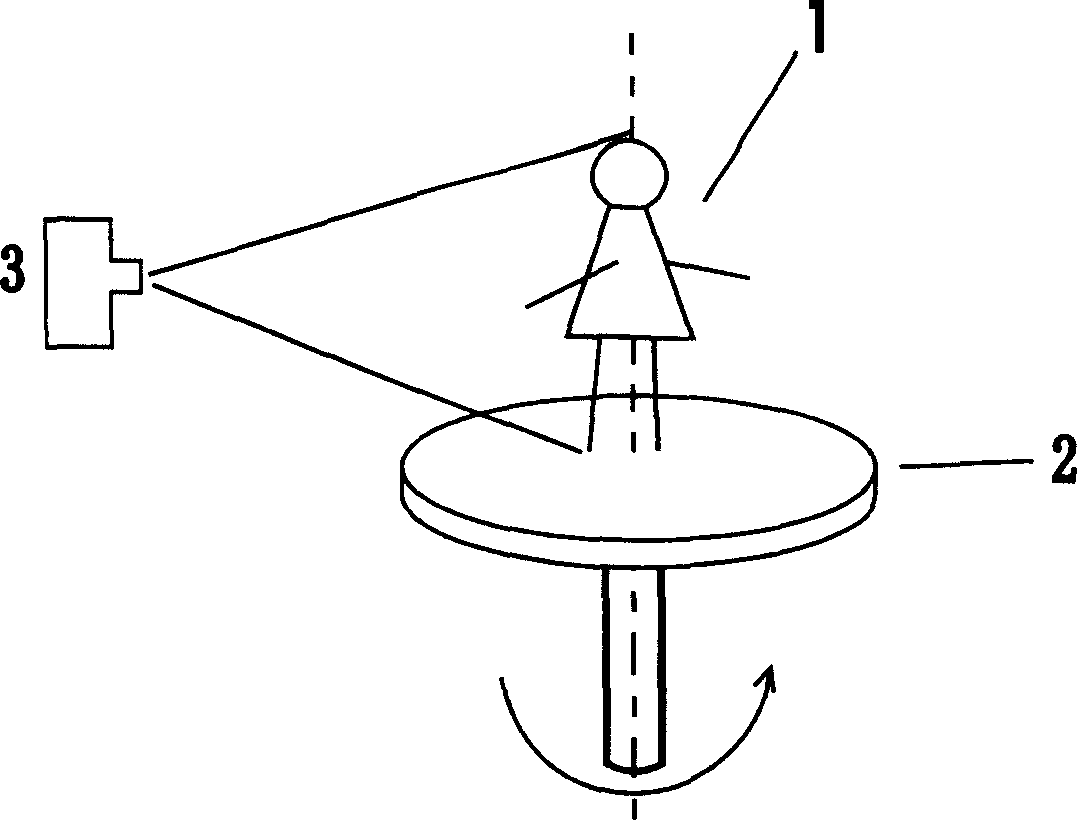

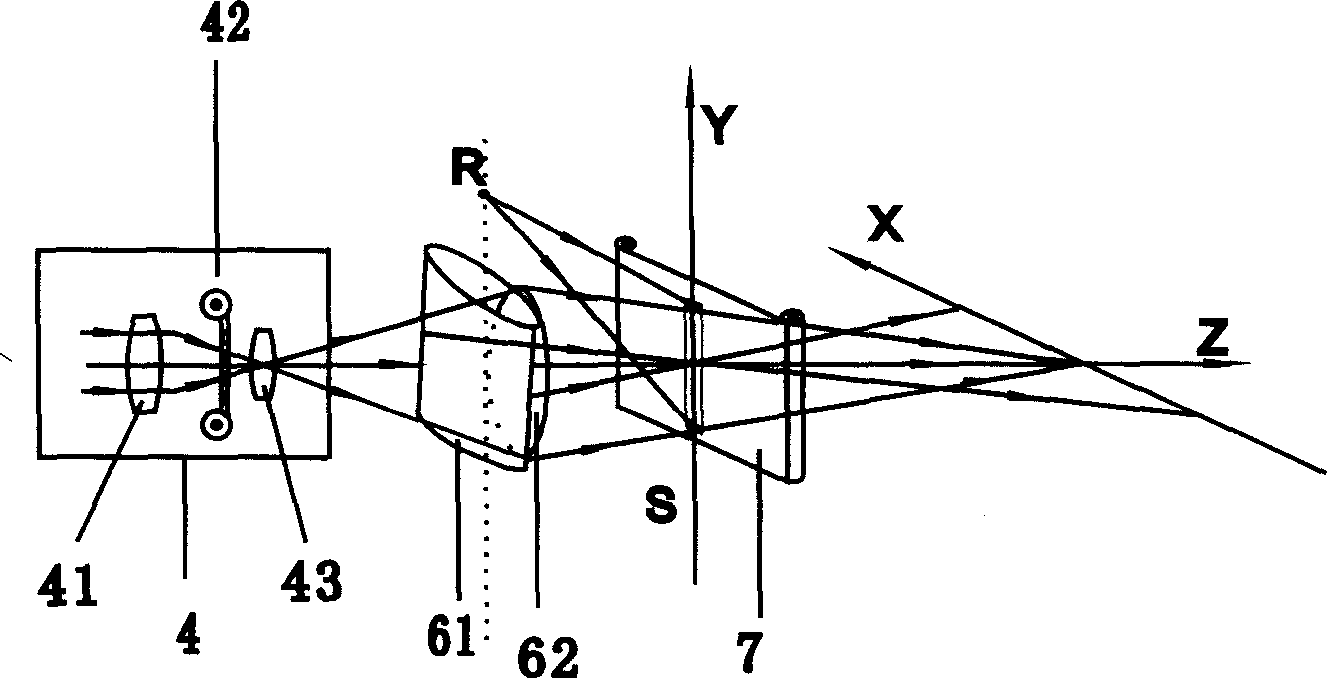

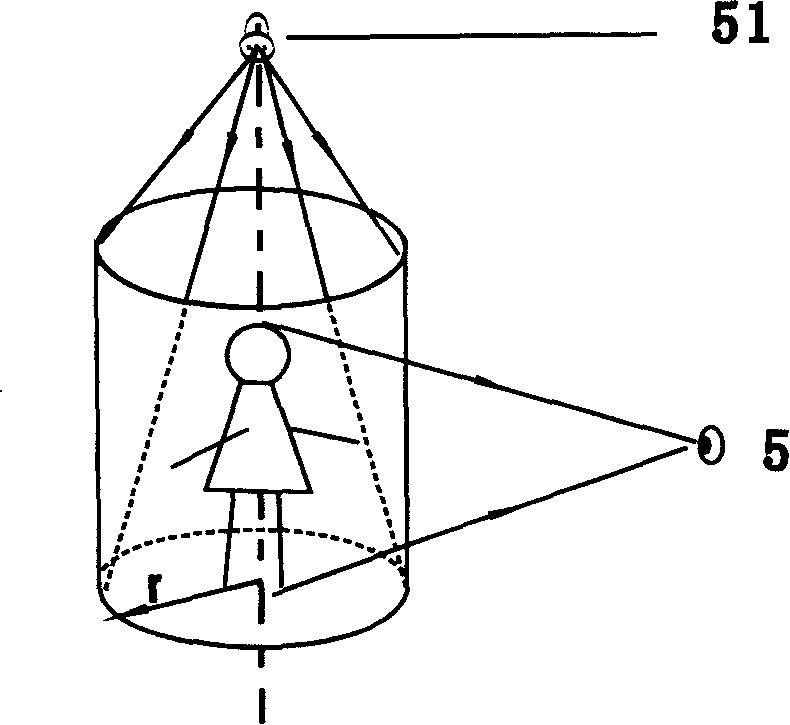

[0041] The production principle of the traditional cylindrical hologram is as follows: After collecting N images of different viewing angles (take the 360° viewing angle as an example, such as figure 1 shown), the nth pattern is projected onto the cylindrical lens 61 and the field lens 62, and the pattern is compressed to the vicinity of the hologram by the cylindrical lens 61 to form a narrow strip-shaped unit hologram for recording, and N All images are compressed onto the holographic recording material 7 to form a cylindrical hologram. Therefore, the radius r of the finally formed cylindrical hologram is equal to the distance from the holographic recording material 7 to the cylindrical lens 61 and depends on the radius of curvature of the cylindrical lens 61 . Fig. 4 shows the imaging process of each unit hologram during the reproduction p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com