Process technique for hollow out stone embossment and adopted carving machine

A processing technology and stone technology, applied in the field of engraving machines, can solve the problems of inability to form large-scale batch production, low production efficiency, and high processing difficulty, and achieve the effects of saving precious stones, improving production efficiency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

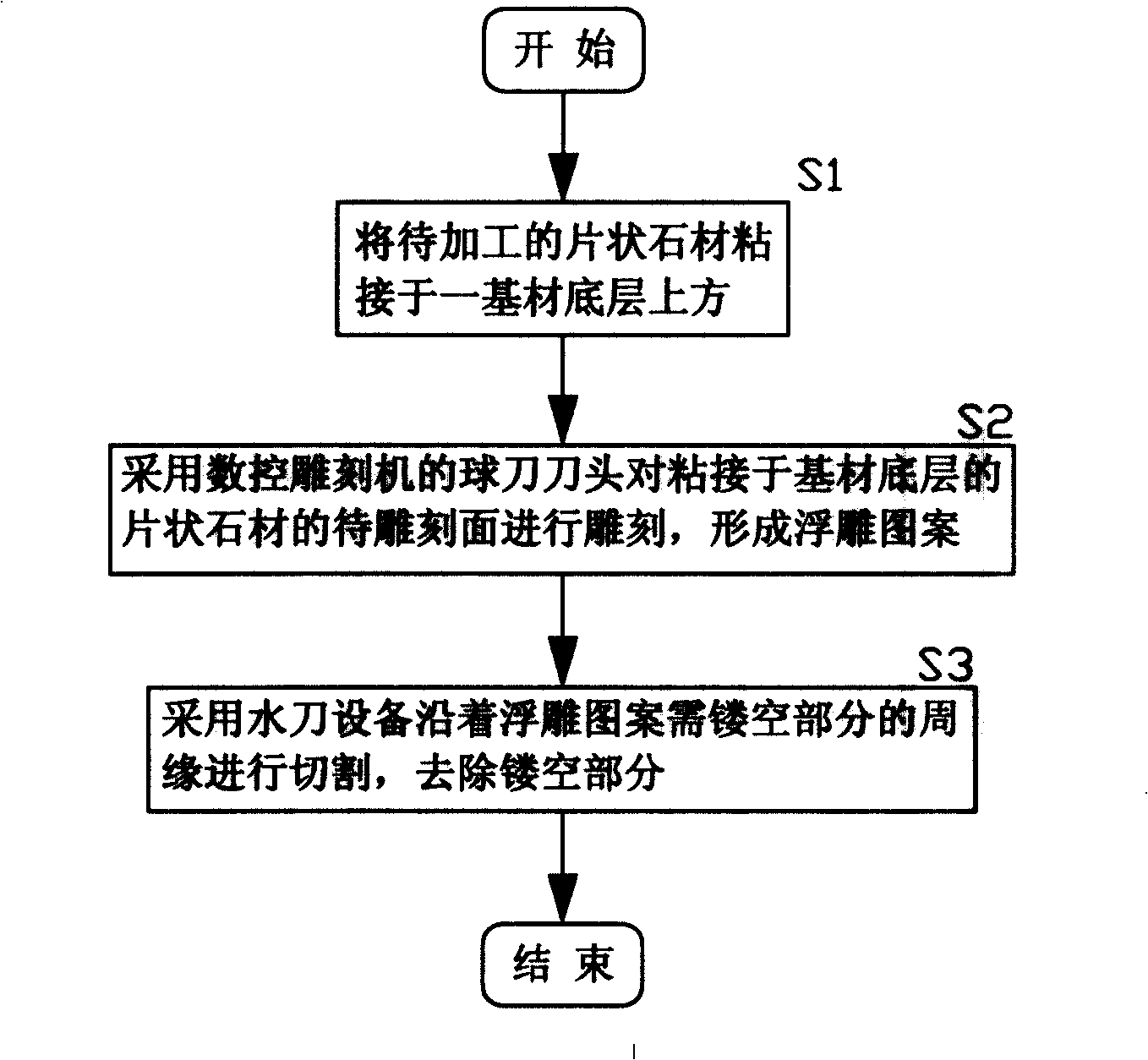

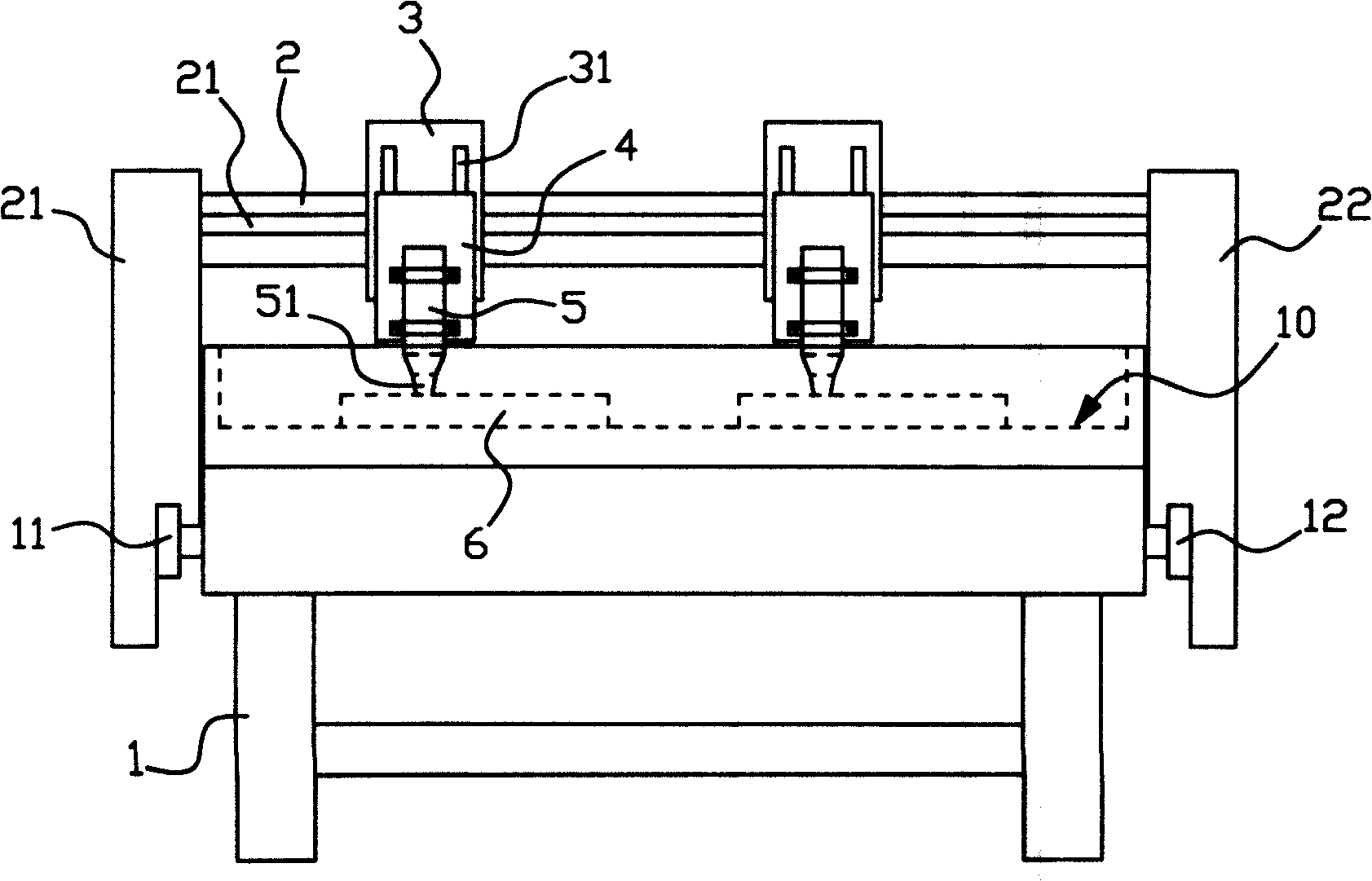

[0015] The invention provides a processing technology for hollow stone relief and the engraving machine adopted. The main point is to firstly use a ball cutter head to carve, and then cut with a water jet to remove the redundant part to form a hollow relief. The whole processing process adopts numerical control. The engraving machine does it automatically. Refer below figure 1 and figure 2 Specific embodiments of the present invention will be described.

[0016] refer to figure 1 , the processing technology of the hollow stone relief comprises the following steps:

[0017] Firstly, the stone material to be processed is bonded on a base layer (step S1). The bottom layer of the base material can be other stone materials, or all other available boards. Its main purpose is to prevent the stones to be processed from being broken during subsequent processing, and also to save stones. Cheaper boards can be used as linings for processing Below the stone, the amount of more expen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com