Plasma flat plate light source

A flat light source, plasma technology, applied in the direction of gas plasma lamps, etc., can solve the problems of short medium discharge path and difficult to generate positive column discharge, and achieve the effect of improving luminous efficiency, luminous efficiency and brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

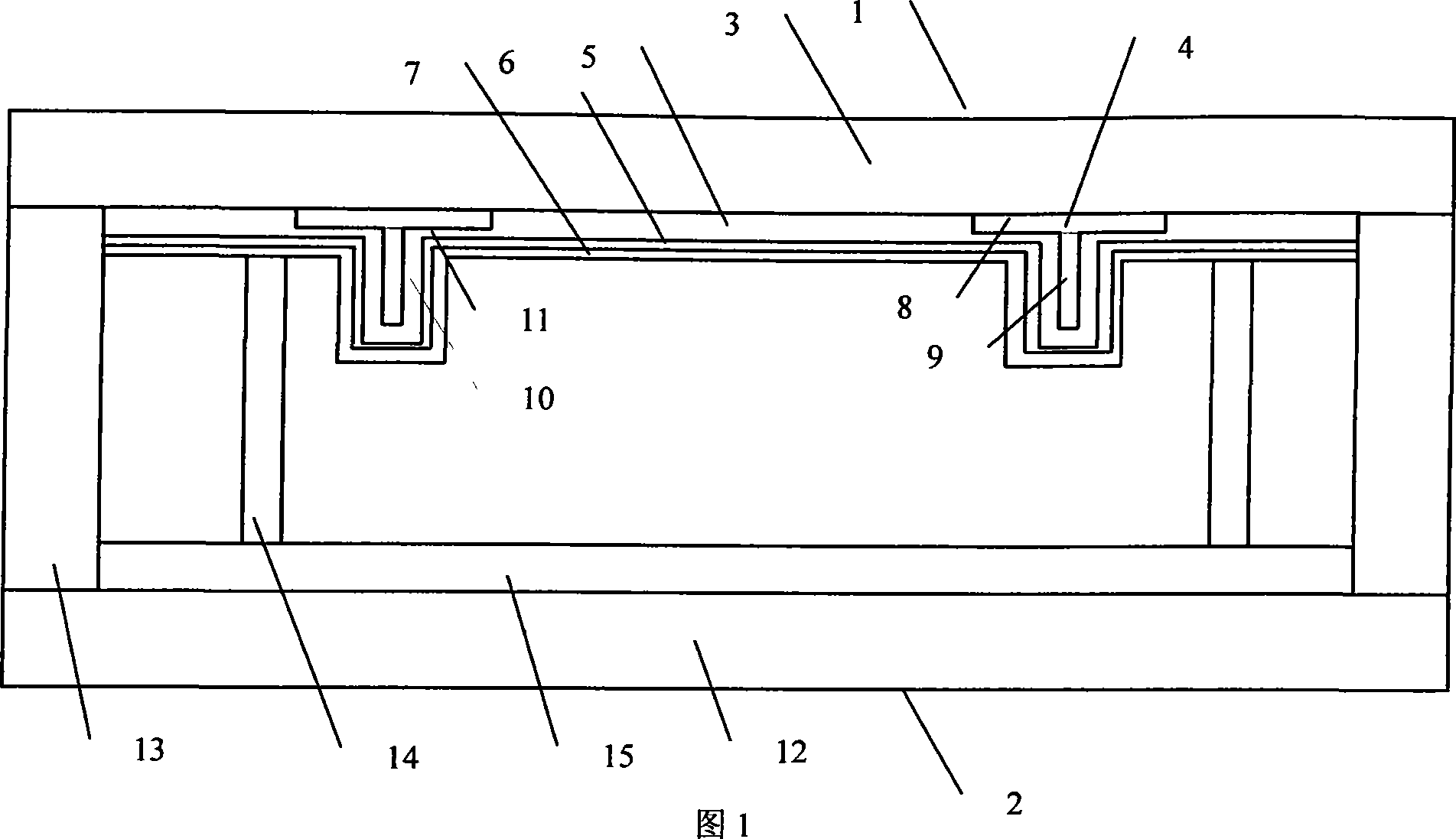

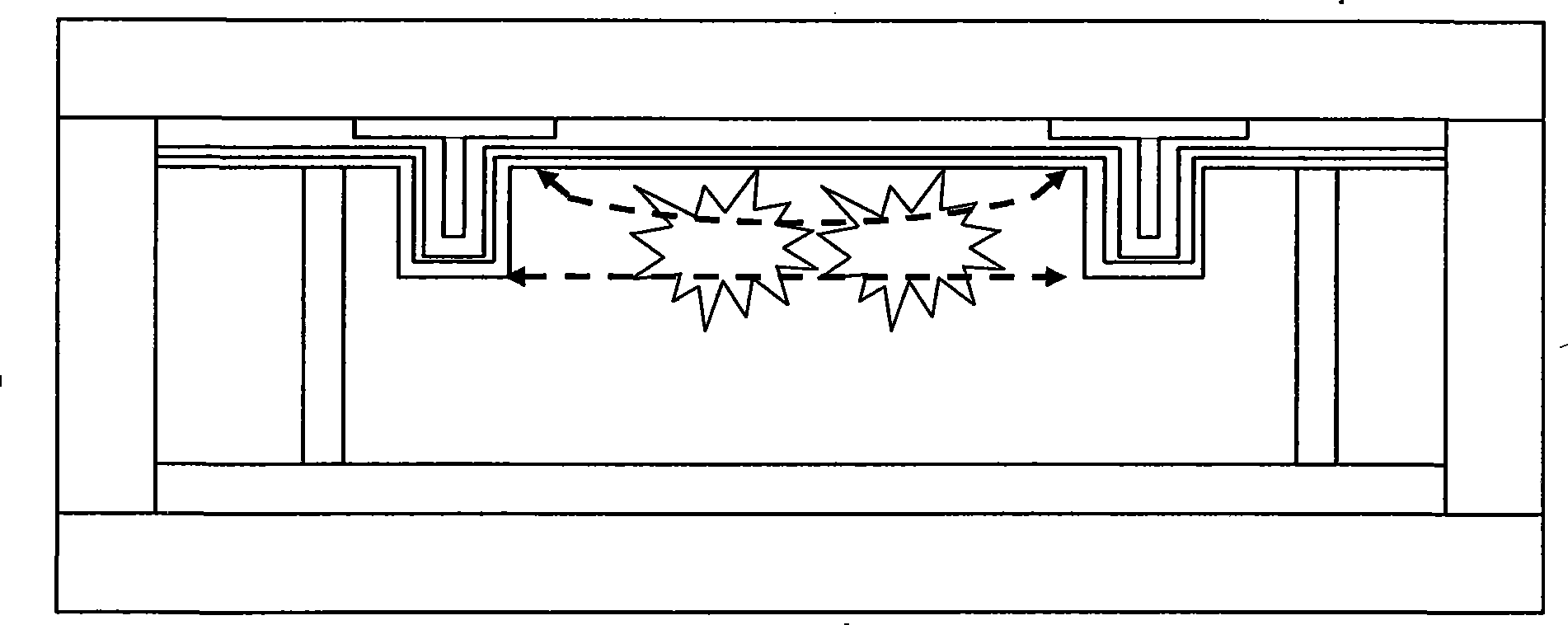

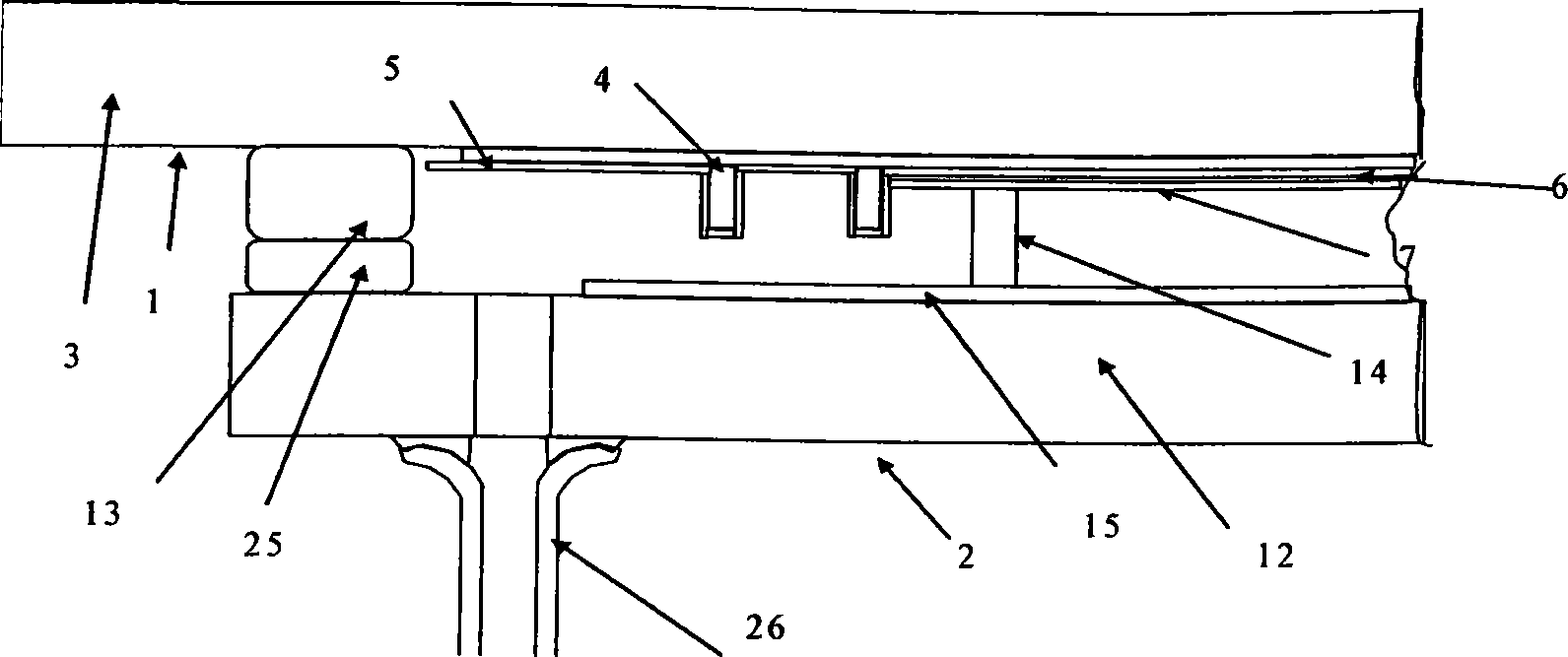

[0025] As shown in Figures 1 to 6, a plasma panel backlight with a three-dimensional three-dimensional electrode structure includes a front substrate 1 and a rear substrate 2, and the front substrate 1 is mainly composed of a front substrate glass substrate 3, a three-dimensional electrode 4, Dielectric layer 5, thin phosphor layer 6, and protective film 7. The three-dimensional electrode consists of a planar electrode 8 on the surface of the glass substrate 3 and an electrode 9 with a certain three-dimensional shape connected to the planar electrode 8. The dielectric layer 5 covers the three-dimensional On the electrode 4, the dielectric layer 5 is composed of a dielectric layer 10 surrounding the electrode 9 and a dielectric 11 covering the surface of the planar electrode 8, a thin phosphor layer 6 is coated on the surface of the dielectric layer 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com