Non-aqueous electrolyte secondary battery

A non-aqueous electrolyte, secondary battery technology, applied in non-aqueous electrolyte batteries, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problem of inability to effectively use battery shell space, increase in electrode group diameter, cycle characteristics and reliability. Sexual decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

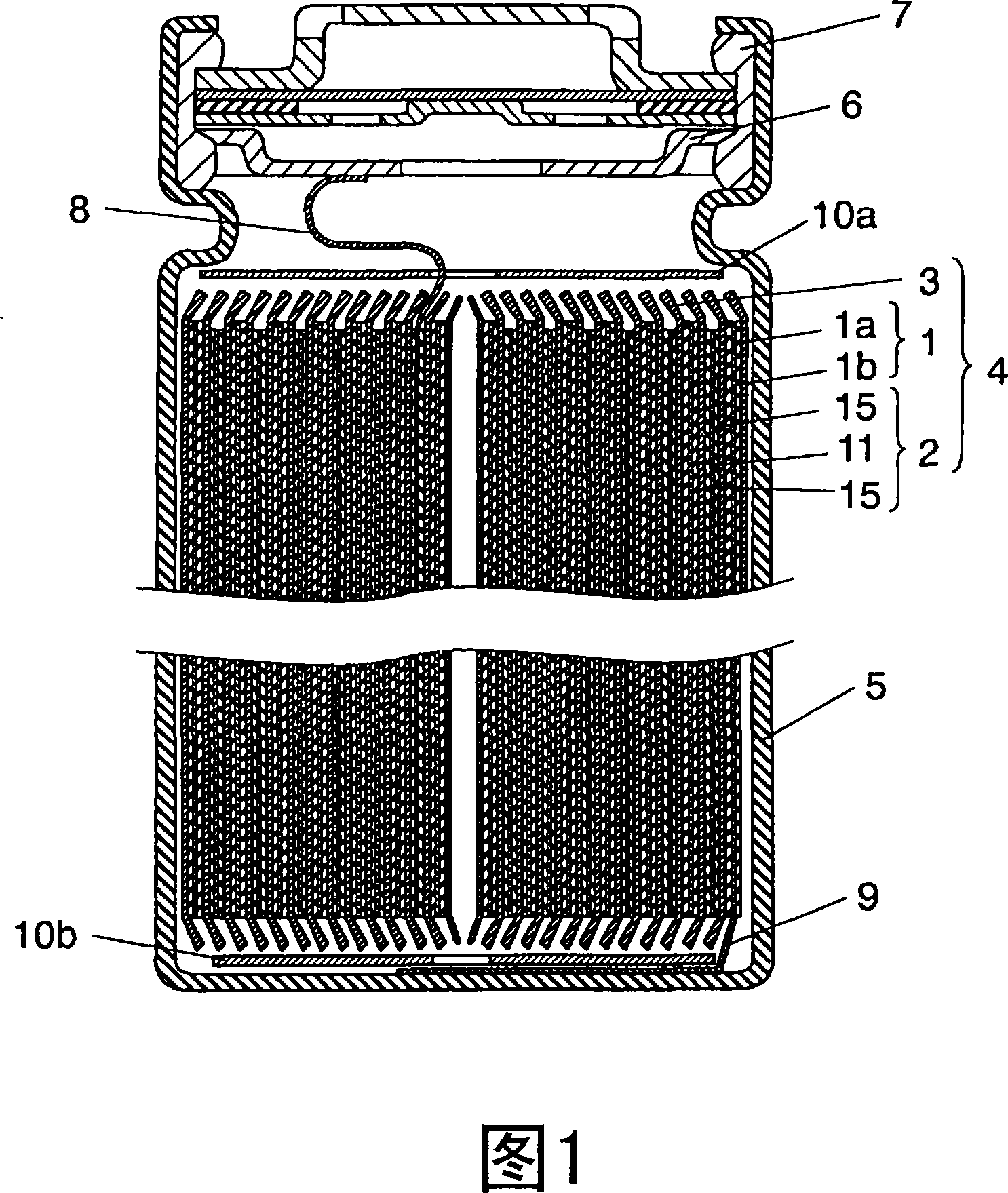

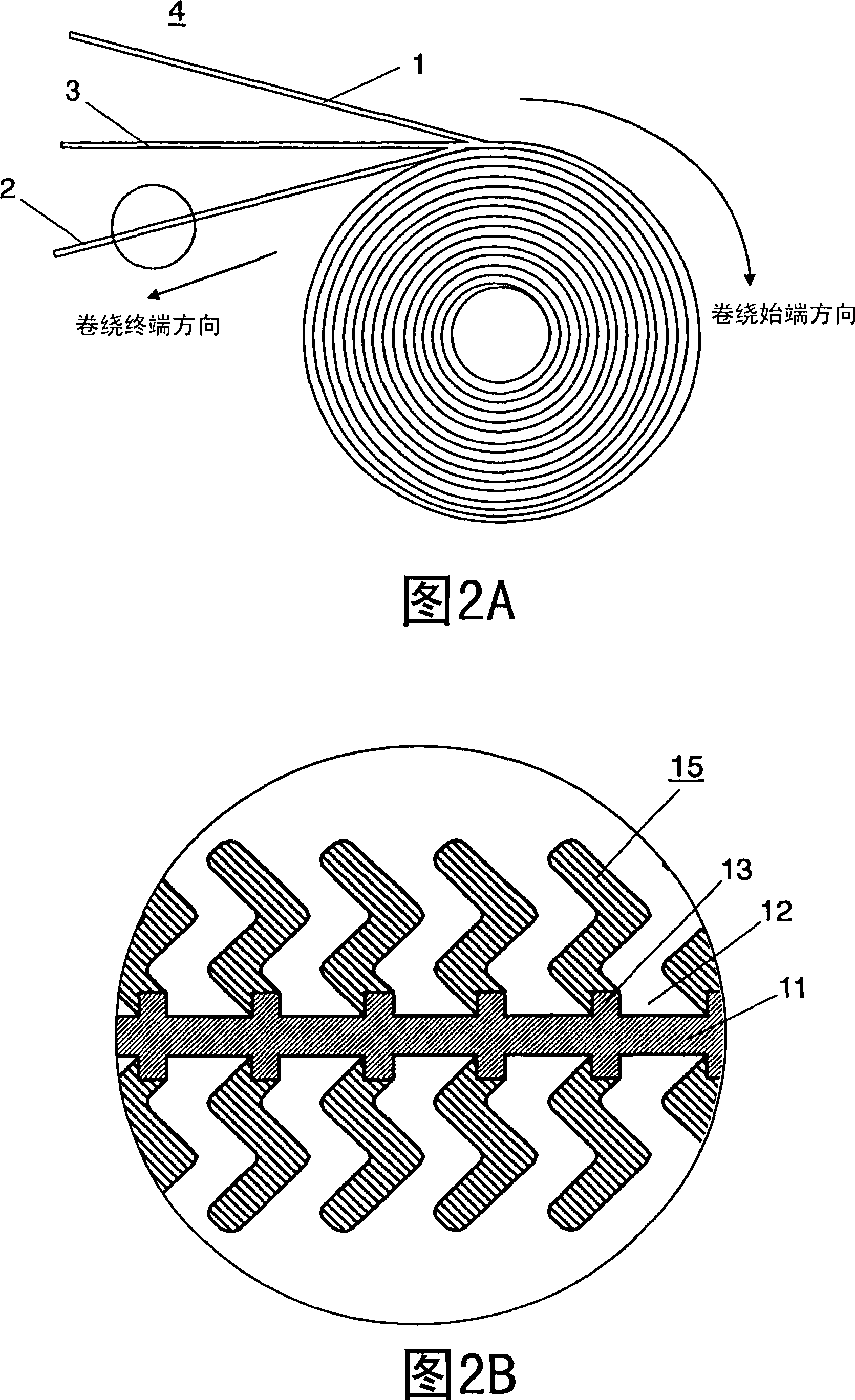

[0037] 1 is a cross-sectional view of a nonaqueous electrolyte secondary battery in Embodiment 1 of the present invention; FIG. 2A is a plan view schematically showing a wound state of an electrode group of a nonaqueous electrolyte secondary battery in Embodiment 1 of the present invention; FIG. 2B is a partially enlarged cross-sectional view illustrating in detail the structure of the negative electrode of FIG. 2A .

[0038] As shown in FIG. 1 , a cylindrical nonaqueous electrolyte secondary battery (hereinafter referred to as "battery") has an electrode group 4 in which a separator 3 is inserted into a positive electrode 1 having a positive electrode lead 8 made of aluminum, for example. It is wound as shown in FIG. 2A between the negative electrode 2 facing the positive electrode 1 and having a negative electrode lead 9 made of copper at one end. And, the insulating plates 10a, 10b are installed on the upper and lower sides of the electrode group 4, then inserted in the bat...

Embodiment approach 2

[0082] 9A is a partially enlarged cross-sectional view showing the structure of the negative electrode according to Embodiment 2 of the present invention; FIG. 9B is a schematic diagram illustrating changes in x values in the width direction of active materials constituting each columnar body part according to Embodiment 2 of the present invention. In addition, in this embodiment, since the cylindrical battery similar to FIG. 1 is used, detailed description is abbreviate|omitted. In addition, the constituent materials of the positive electrode mixture layer, the positive electrode current collector, the negative electrode current collector, and the columnar body are also the same as those in Embodiment 1, and thus detailed description thereof will be omitted.

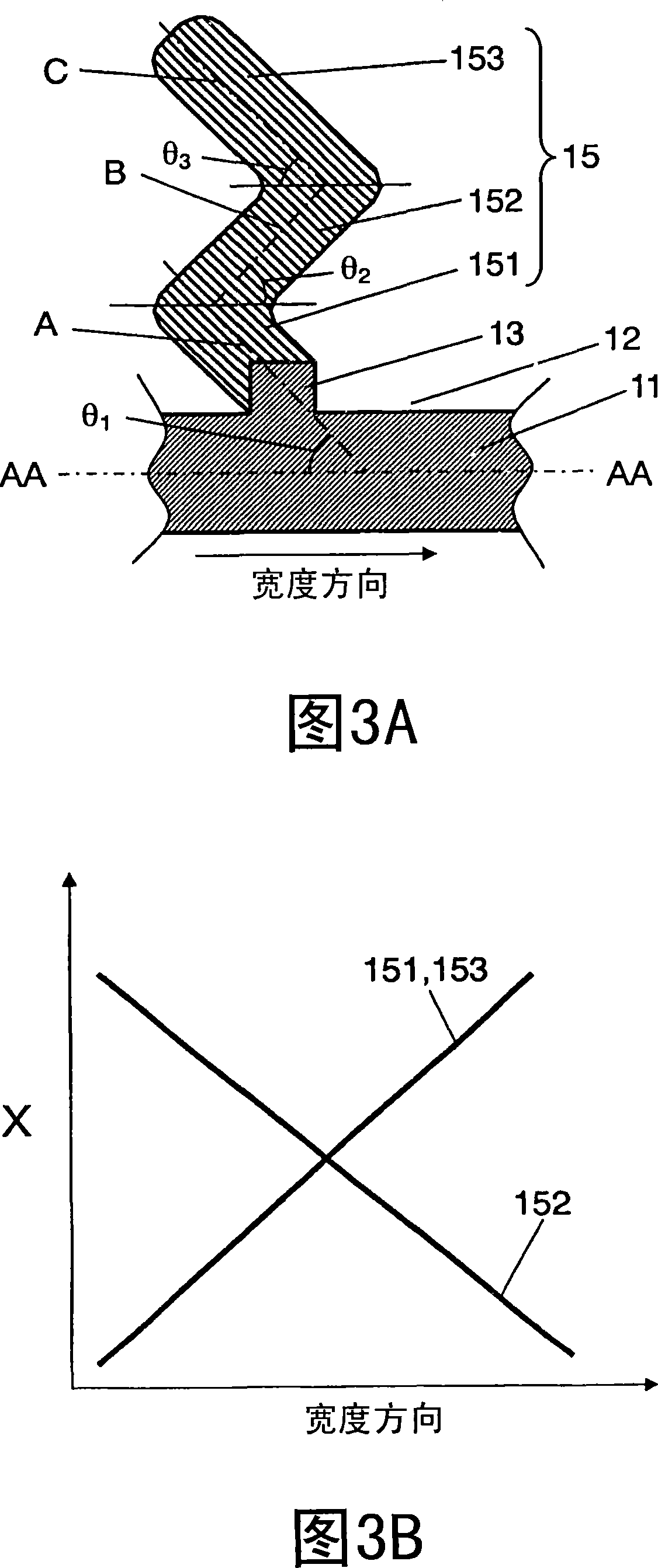

[0083] The difference between this embodiment and Embodiment 1 is that in this embodiment, the entire columnar body composed of n=7 columnar body parts is placed on the convex part of the current collector and obliquel...

Embodiment 1

[0104] The columnar body of the negative electrode was produced using the production apparatus shown in FIG. 8 .

[0105] First, as a current collector, a strip-shaped electrolytic copper foil having a thickness of 30 μm was used on the surface of which protrusions were formed at intervals of 20 μm by a plating method.

[0106] Then, using Si as the active material of the negative electrode, using an evaporation unit (integrated by an evaporation source, a crucible, and an electron beam generator), the oxygen with a purity of 99.7% is introduced into the vacuum container from the oxygen introduction nozzle, Made of SiO x Constructed one-stage columnar body part whose x value changes in the width direction. At this time, an oxygen atmosphere at a pressure of 3.5 Pa was formed inside the vacuum vessel. In addition, during vapor deposition, the electron beam generated by the electron beam generator is deflected by the deflection yoke and irradiated onto the vapor deposition sou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com