Superconducting engine

An engine and superconducting technology, applied in the usage of superconducting elements, electromechanical devices, electrical components, etc., can solve the problems of harmful heat, low energy consumption, iron loss, etc., and achieve long service life, low energy consumption and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

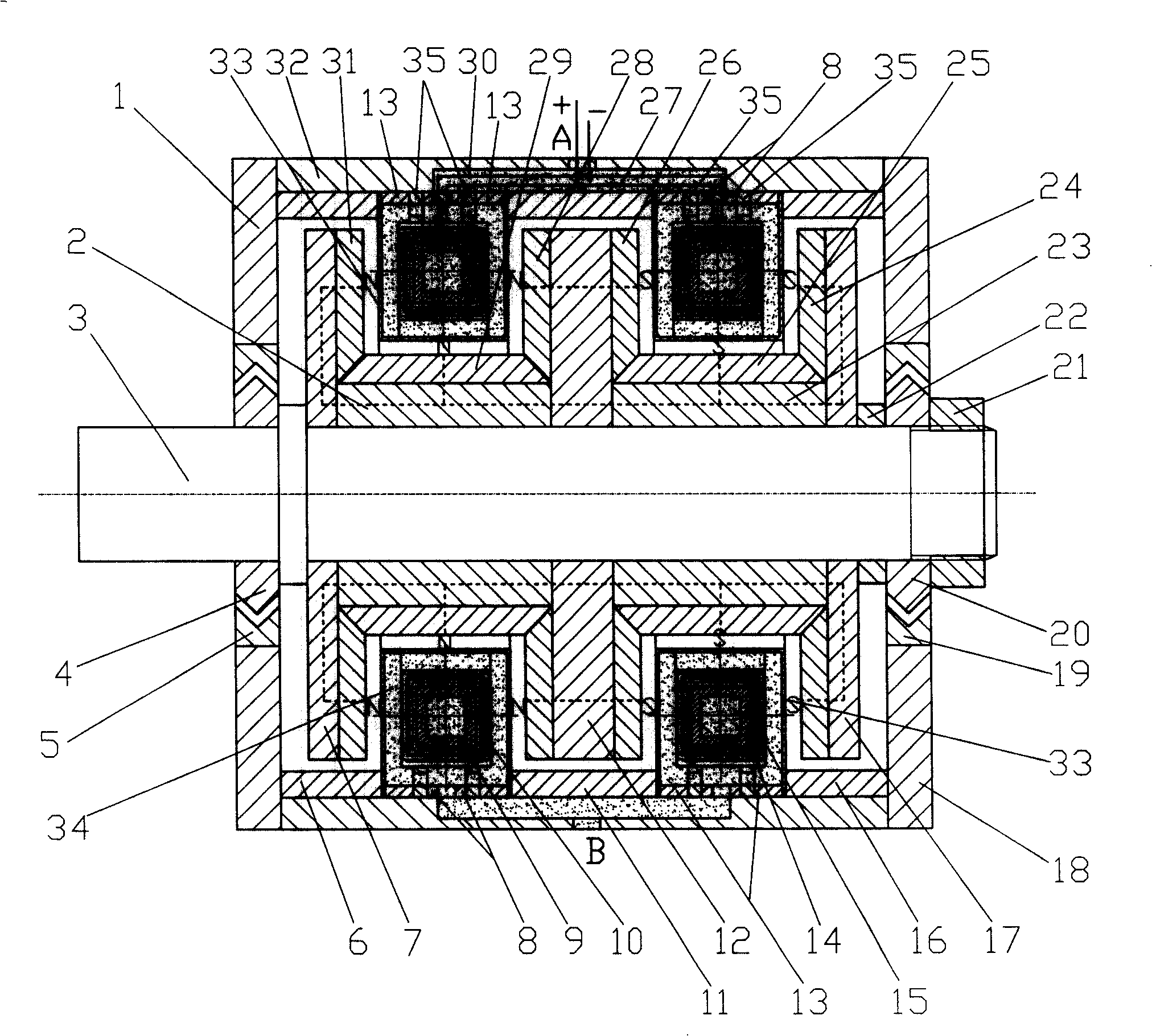

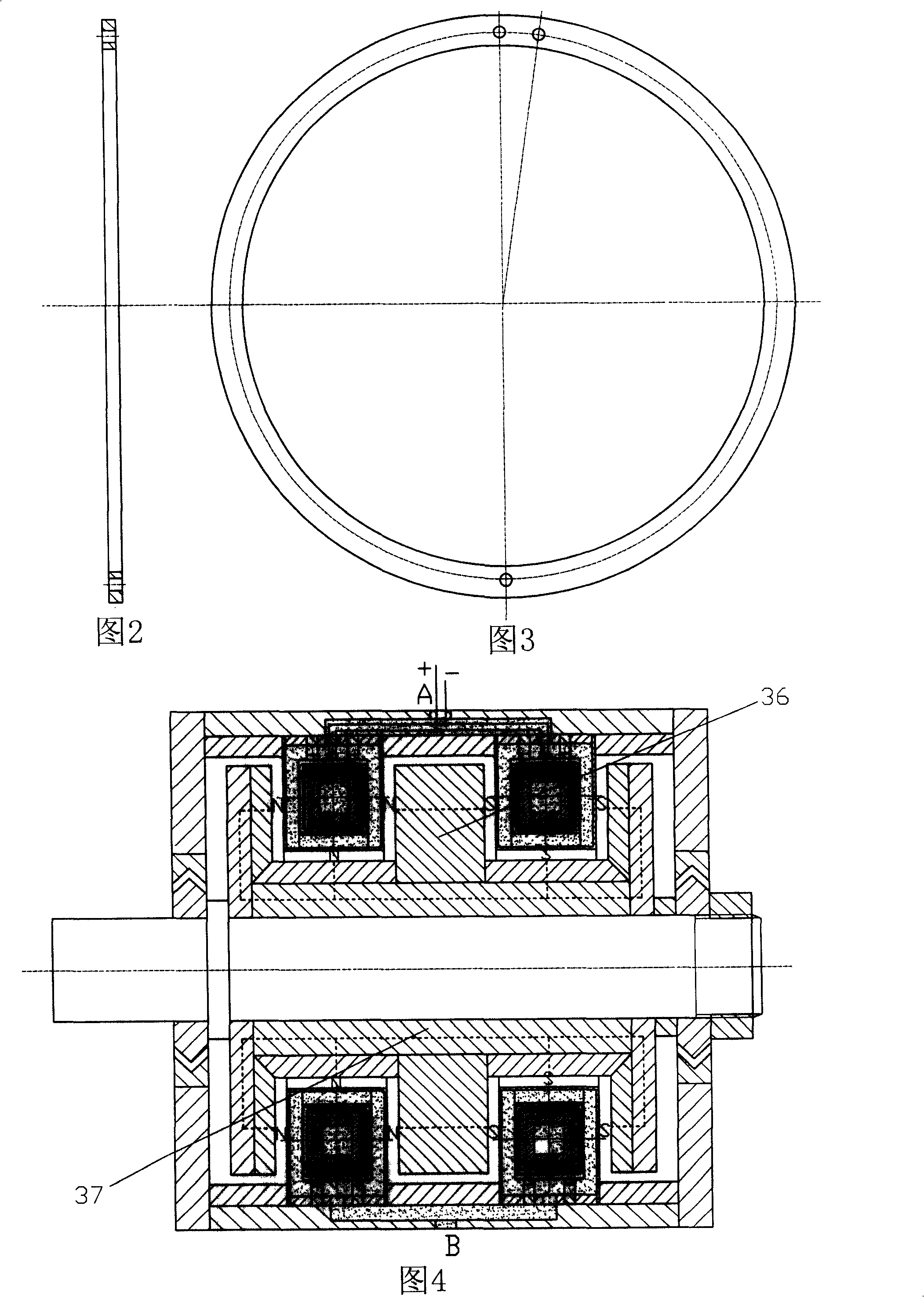

[0033] Specific embodiment one: as shown in Figure 8, the present invention---the composition of superconducting motor: in host machine 97 (such as figure 1 Fig. 4 shows) externally connects refrigerant liquid thermal insulation container 93, the A mouth of main frame 97 communicates with thermal insulation container 93, B port joins with thermal insulation pipeline 91, the superconducting armature coil 10 and 15 of main frame 97 are connected The power supply end of the external power supply is connected with a superconducting wire with low thermal conductivity in the refrigerant container 93, and a superconductor 92-2 of a superconducting switch 92 is connected in parallel between the positive and negative contacts, and the superconductor 92-2 is externally placed near the superconductor 92-2 The most common heating wire 92-1, the power supply switch 86 of the heating wire 92-1 is connected to the two ends of the heating wire 92-1 with the superconducting wire of low thermal ...

specific Embodiment approach 2

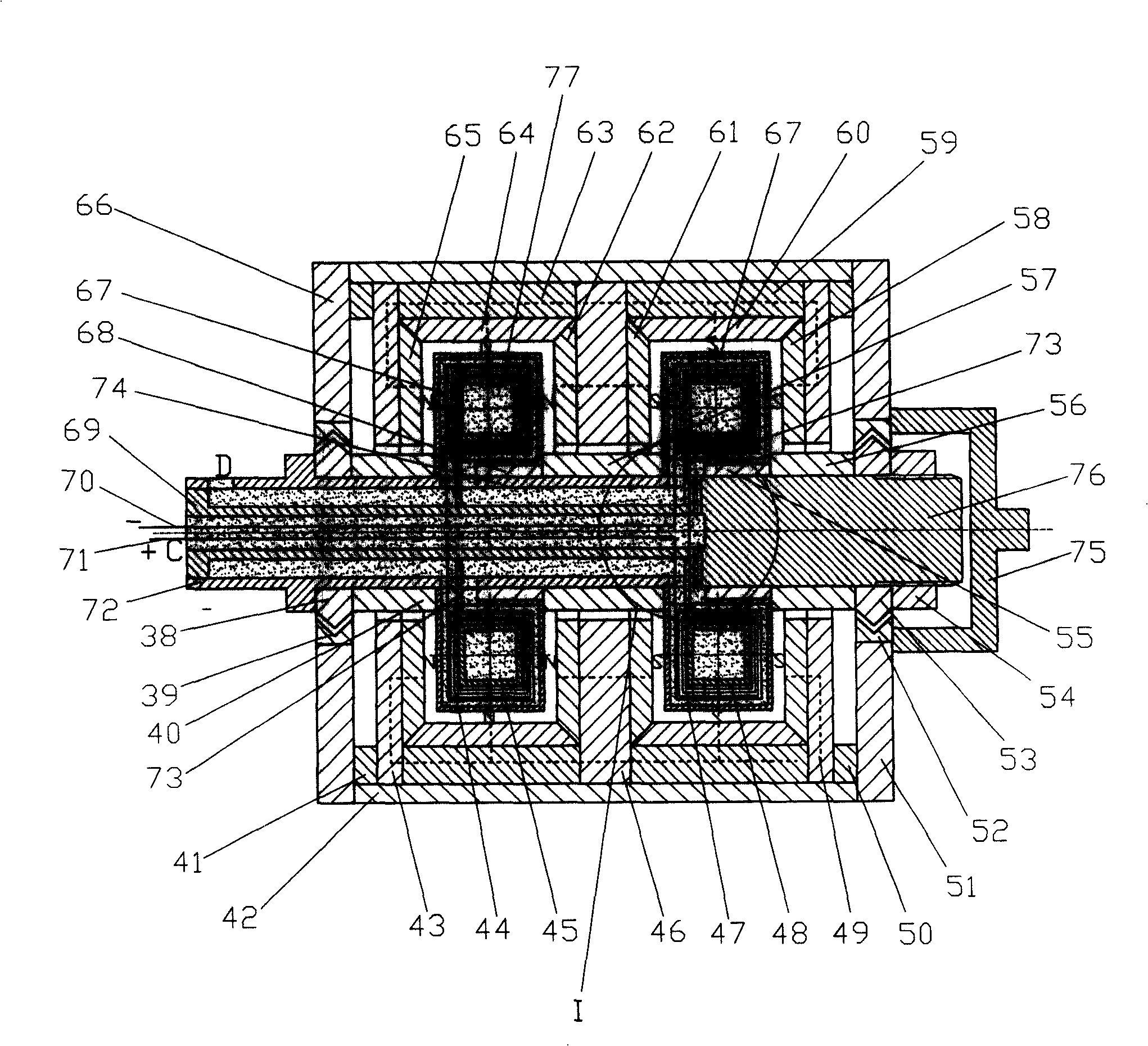

[0039] Specific implementation mode two: as Figure 9 shows that the host 100 (such as Figure 5 Figure 7 (shown) is an outer rotor superconducting direct current motor, its shaft end face is connected with the thermal insulation container 93, the C port is connected with the thermal insulation container 93, and the D port is connected with the thermal insulation pipeline 91; the rotating shaft of the generator 101 is connected to the The rotor shaft 75 of the main engine 100 is connected, and the external user equipment 102 can be connected with the shaft of the generator 101 through a coupling or a clutch 95 . The remaining parts are the same as those in Embodiment 1.

[0040] The main engine 100 is respectively served by two kinds of outer rotor superconducting DC motors.

[0041] Such as Figure 5 Figure 6 Shown, the first outer rotor type superconducting DC motor, its rotor is constituted like this: at the two ends of the circular permanent magnet 64 of radial magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com