Cereal flow measuring device of combine-harvester and yield measure method of combine-harvester

A technology of combine harvester and measuring device, applied in the direction of measuring device, harvester, weighing, etc., can solve the problems of mass flow measurement accuracy, humidity and moisture content, unreliable work, complex structure, etc., to eliminate grain The effect of different surface moisture content, simple and reliable use, and accurate yield information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

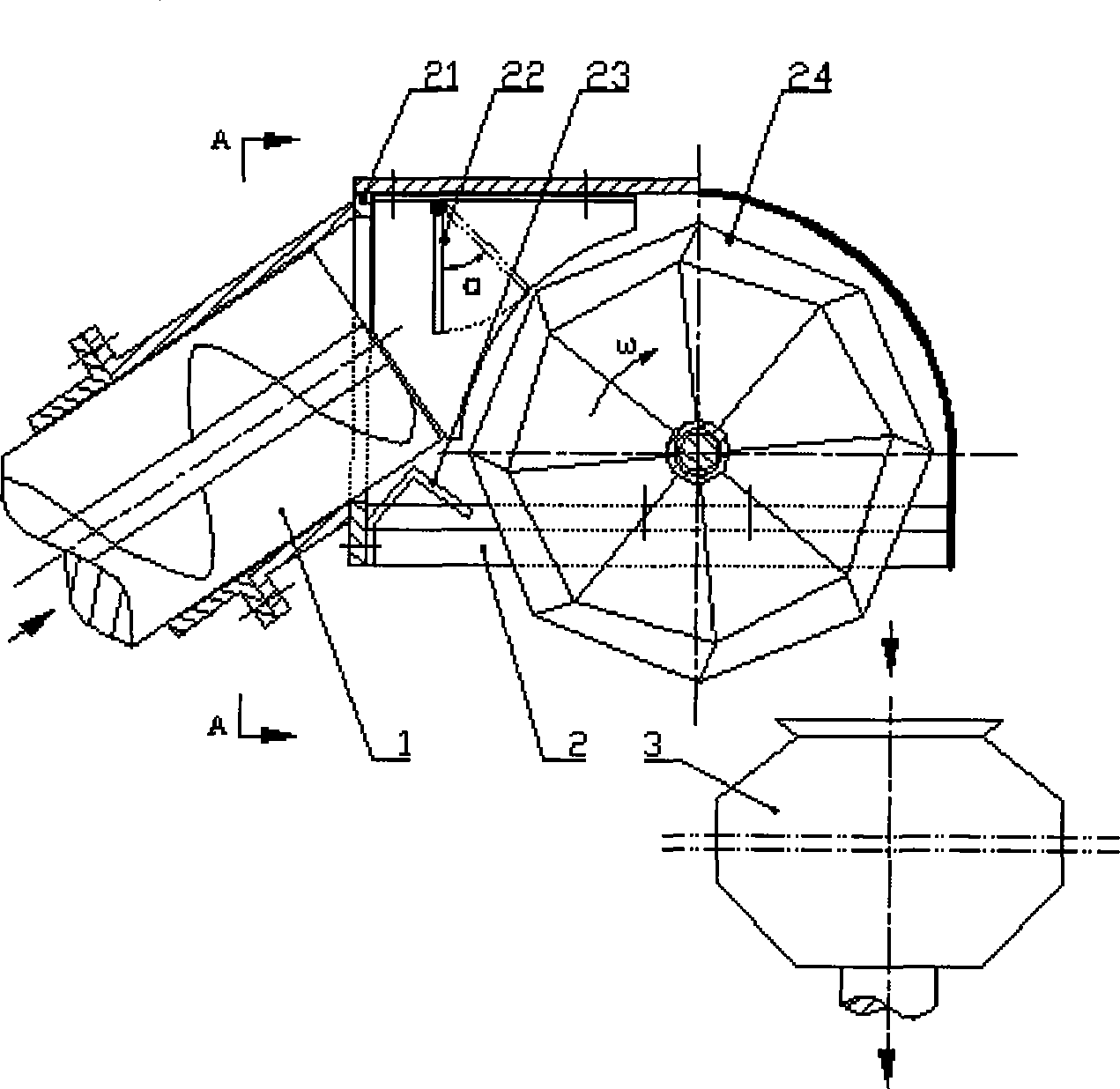

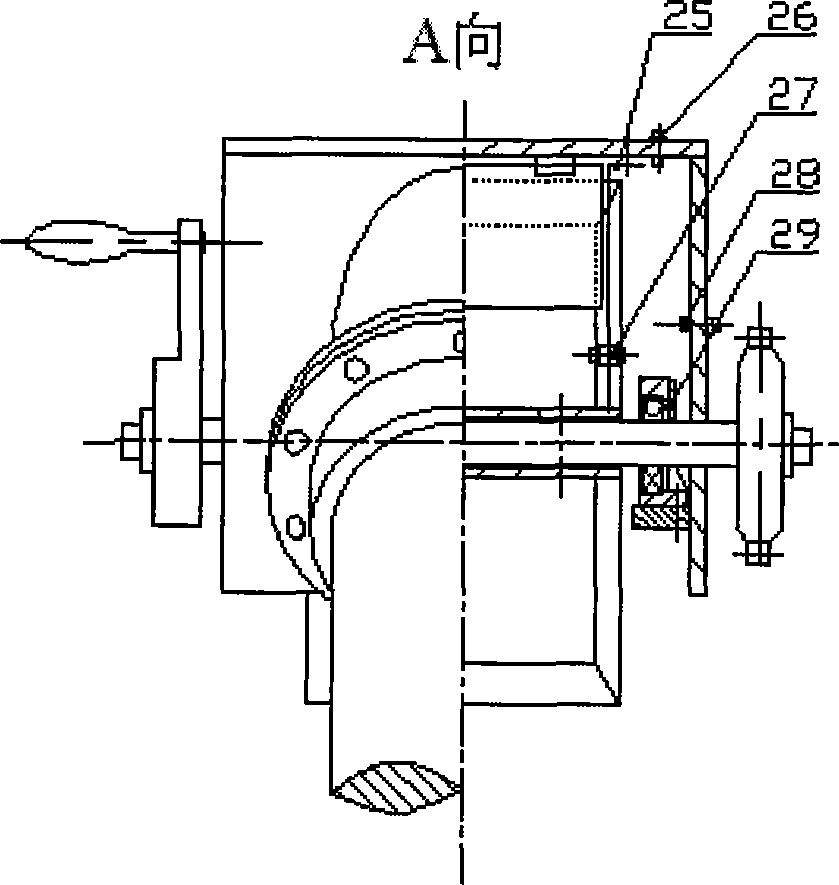

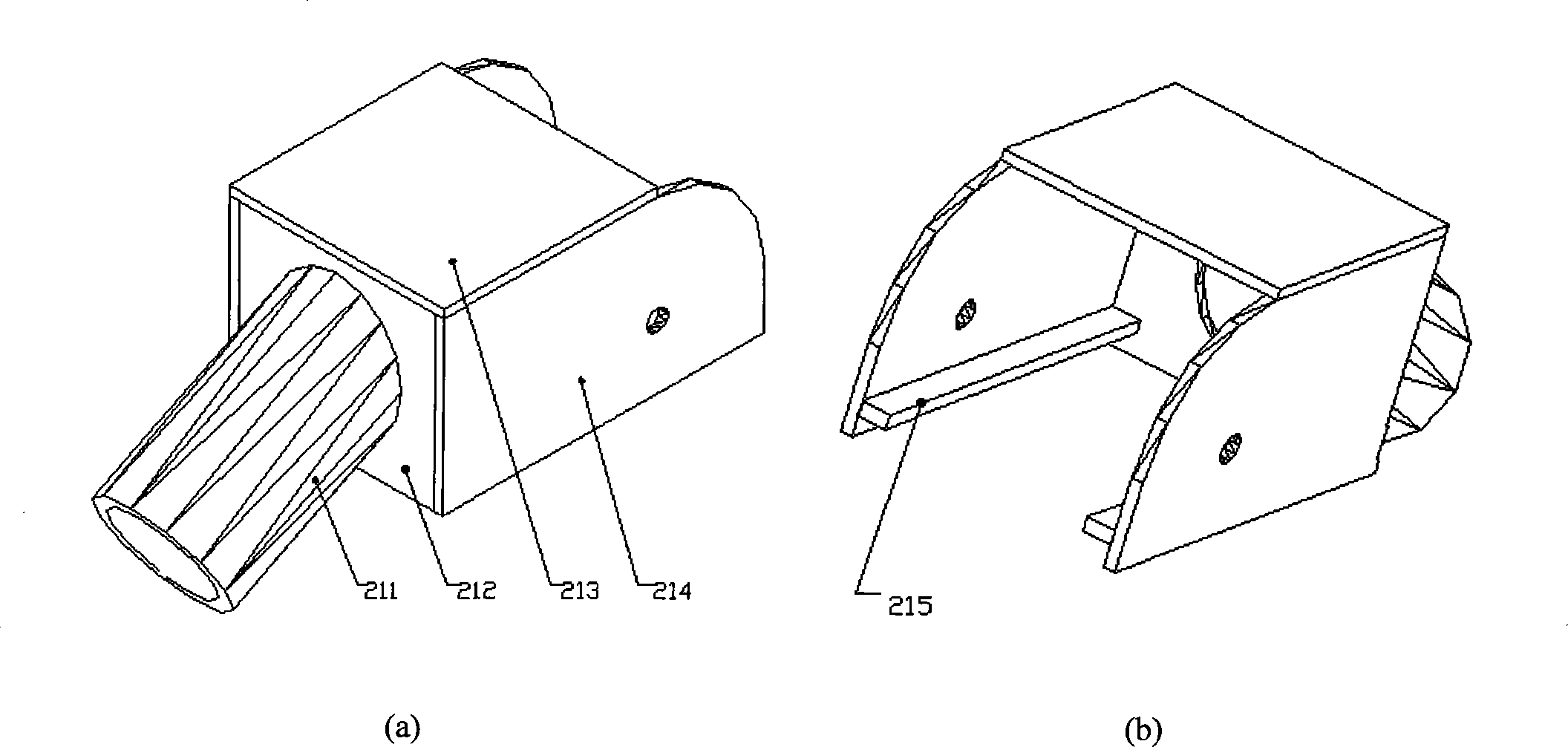

[0026] Such as Figure 1~3 As shown, the outlet of the stirring cage 1 is connected to the inlet of the measuring device 2, and the outlet of the measuring device 2 is above the barn 3, and the grain discharged from the stirring cage 1 passes through the measuring device 2 and then put into the barn 3. The measuring device 2 includes a casing 21, an upper baffle mechanism 22 and an air humidity sensor 26 are installed on the top of the casing 21, a lower baffle 23 is installed below, side baffles 25 are installed on the front and rear sides, and the measurement is installed directly in front of the support bearing component 29. Axle part 24; Grain humidity sensor 27 is installed on the bottom of side baffle plate 25, and proximity switch 28 is installed near measuring wheel axle part 24 side. Air humidity sensor 26, grain moisture content (or humidity) sensor 27 and proximity switch 28 and counting interface are connected to microcomputer system.

[0027] The function and pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com