Automobile auxiliary current transformer

A vehicle auxiliary and inverter technology, applied in vehicle components, current collectors, electric vehicles, etc., can solve the problems of large electromagnetic interference, serious switching noise, large voltage/current spikes, etc., to meet the requirements of lightweight design, The effect of reducing switching noise and switching loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

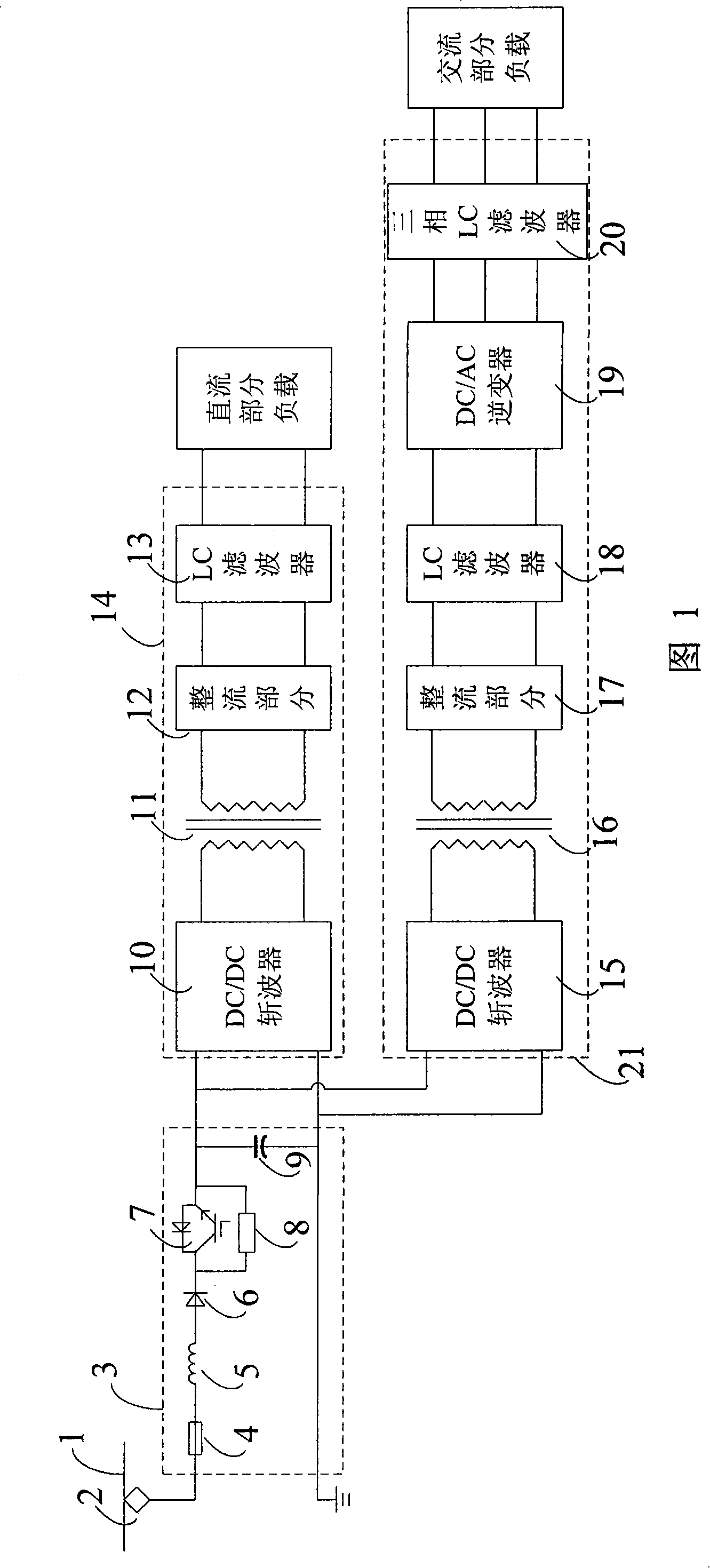

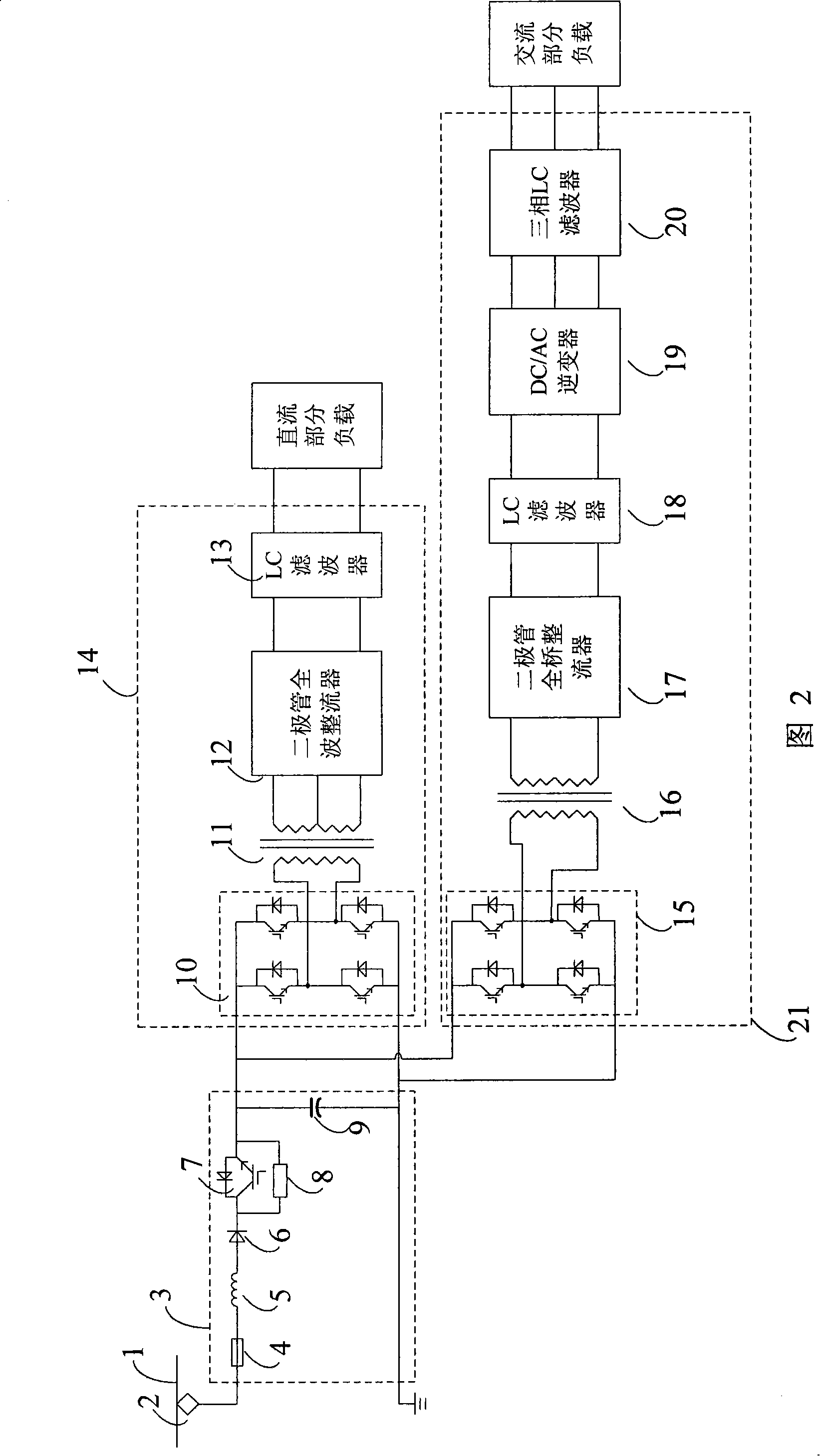

[0020] FIG. 2 shows the configuration of the main circuit of the vehicle auxiliary converter according to Embodiment 1 of the present invention. In the figure, the auxiliary converter obtains power from the overhead line 1 through the pantograph 2 . The overhead line 1 is the third rail of the overhead line or the ground.

[0021] The structure of the grid-side filtering part 3 is as follows: the diode 6 is connected to the collector of the grid-side power switch tube 7, the emitter of the grid-side power switch tube 7 is connected to the positive pole of the filter capacitor 9 to form the positive pole of the DC bus, and the soft-start resistor 8 The two ends are respectively connected to the collector of the grid-side power switch tube 7 and the emitter of the grid-side power switch tube 7 . The fuse 4 in the filter part 3 of the grid side is used to protect the auxiliary converter device, the filter reactance 5 and the filter capacitor 9 form an LC smoothing unit, and the ...

Embodiment approach 2

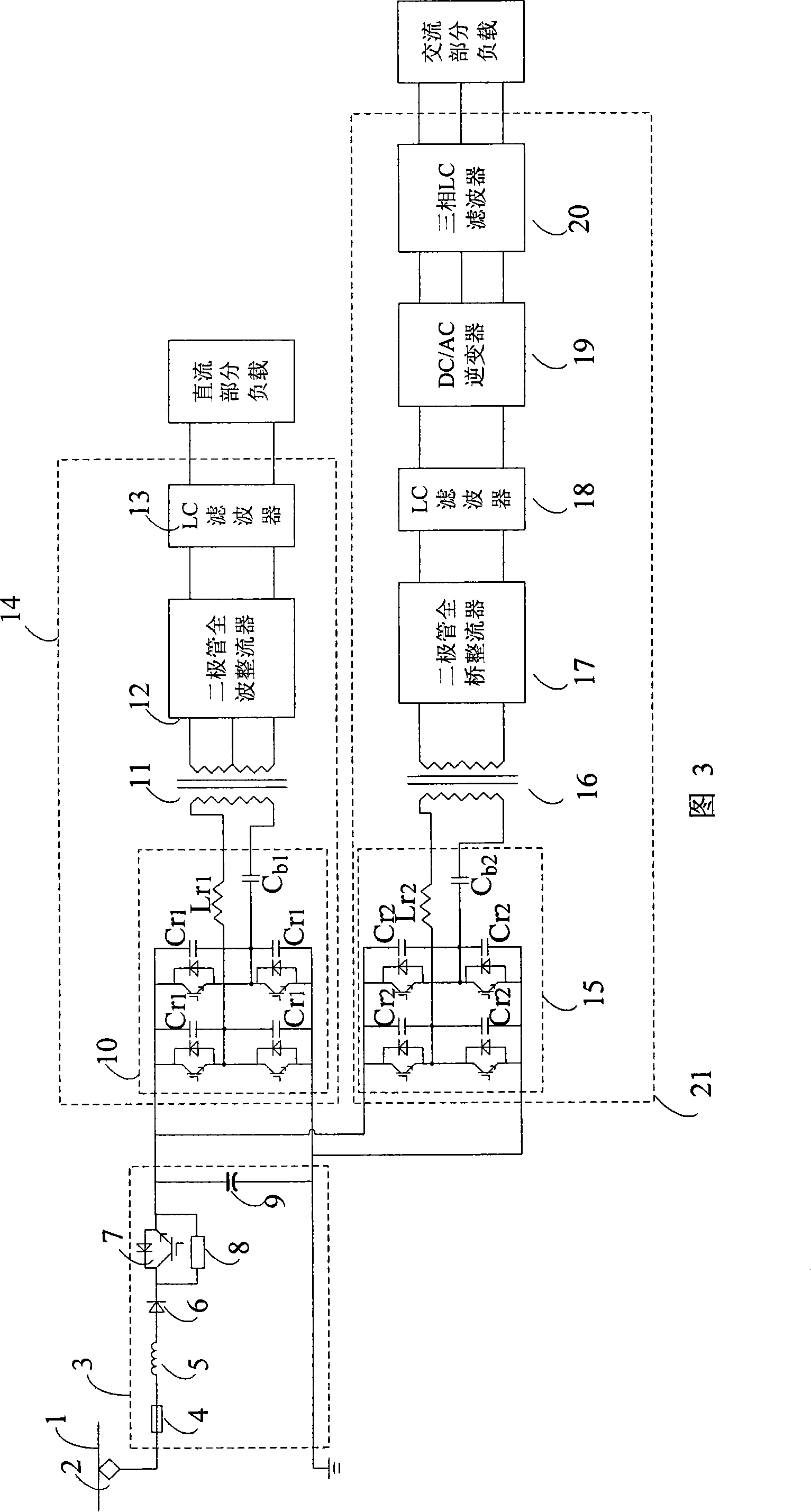

[0025] FIG. 3 shows the configuration of a main circuit of a vehicle auxiliary converter according to Embodiment 2 of the present invention. The circuit topology is basically the same as that described in Embodiment 2, except for the DC / DC chopper 10 in the DC conversion part 14 and the DC / DC chopper 15 in the AC conversion part 21 . In this embodiment, the voltage-type power switching device in the DC / DC chopper works in a state of ZVS soft switching (zero voltage soft switching).

[0026] The main circuit topology of the DC / DC chopper 10 in the DC conversion part 14 is a full-bridge chopper circuit, and a resonant capacitor C is connected in parallel at both ends of each voltage-type power switch tube in the main circuit. r1 , connect the resonant inductor L before the transformer 11 r1 and blocking capacitor C b1 , using phase-shifted full-bridge ZVS PWM control to ensure that before each power switch is turned on, the voltage across its collector and emitter is reduced t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com