Method for manufacturing halogen amine antimicrobial material

An antibacterial material and halamine technology, applied in the field of preparation of amine antibacterial materials, can solve the problems of increasing the difficulty and cost of the preparation of antibacterial materials and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

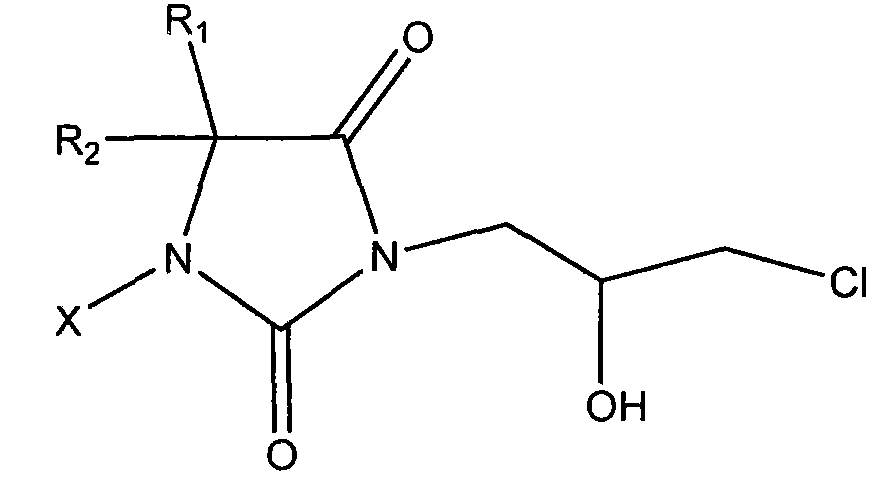

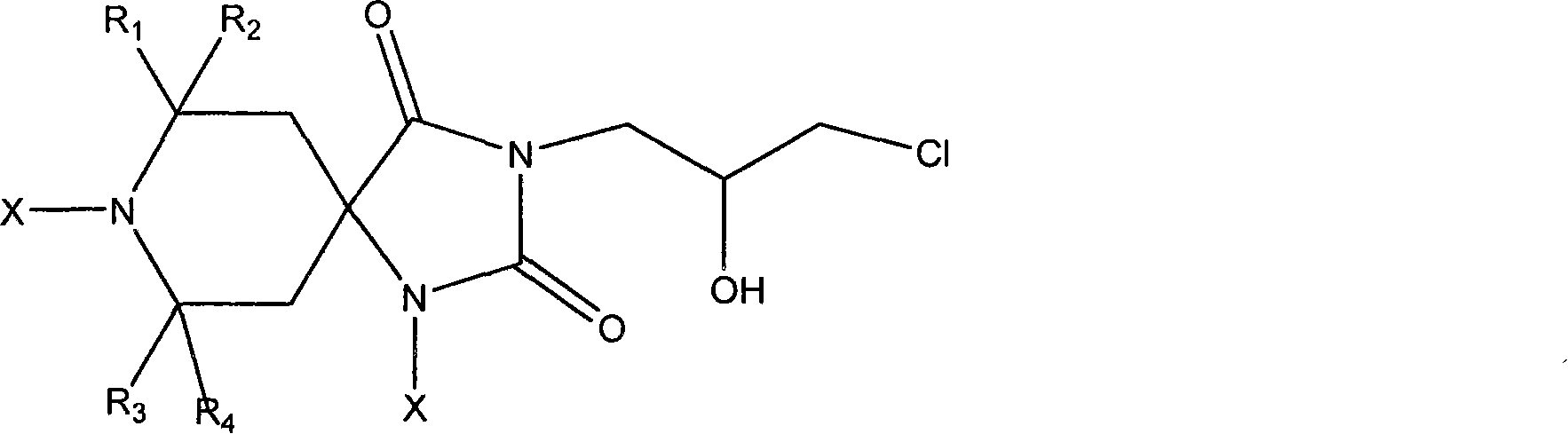

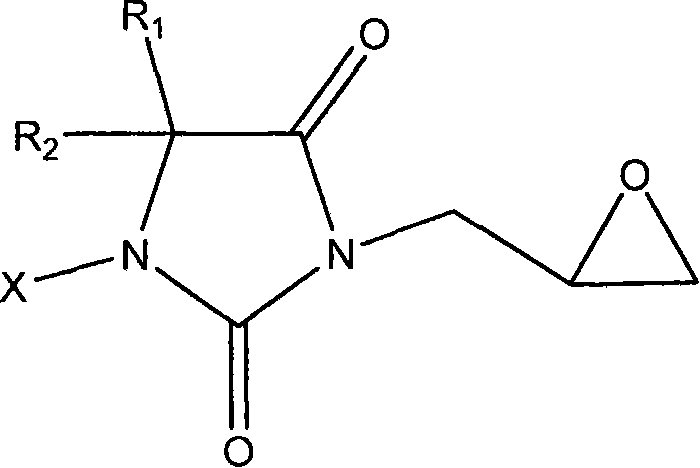

Image

Examples

Embodiment 1

[0033] Add 128g of 5,5-dimethylhydantoin, 3840ml of epichlorohydrin and 0.5g of phenyltriethylammonium chloride into a 5000mL round bottom flask, heat at 120°C for 3 hours, then heat at 60-65°C Excess epichlorohydrin was distilled off under reduced pressure, and 1000 ml of 2% NaOH was added after cooling to obtain a hydantoin derivative solution. Take 50g of pure cotton cloth and soak it in the above liquid, let it stand for 45 minutes, and stir the intermediate space for 3 to 5 times. After taking it out, squeeze it until there is no obvious liquid dripping down, first bake it in an oven at 90°C for 45 minutes, and then bake it at 145°C for 30 minutes. Take it out and wash it with tap water, then soak the washed cloth in 0.1% sodium hypochlorite for 45 minutes, rinse it once with tap water, and dry it in the air or at no more than 55°C. Measured by iodometric method, the chlorine content on the cloth is 0.18% (that is, 0.18 g of active chlorine is contained on 100 g of cloth...

Embodiment 2

[0035] Replace the pure cotton cloth in Example 1 with 100% polyester fiber soaked in 2% NaOH solution for 12 hours in advance, and the other processes are the same as in Example 1. The chlorine content is 0.14%.

Embodiment 3

[0037] After the finishing solution prepared by Example 1 was placed for 30 days, the antibacterial cloth was prepared according to the method of Example 1, and the active chlorine content was recorded to be 0.19%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com