Optical fiber sensing method for synchronously testing temperature and pressure below horizontal well

A technology for testing optical fibers and synchronous testing, which is applied in the directions of measurement, earthwork drilling, borehole/well components, etc. It can solve the problems that the working temperature of the instrument is only suitable and cannot meet the actual needs, and achieve the effect of fast speed and large transmission capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is provided by the following embodiments, which will be described below in conjunction with the accompanying drawings:

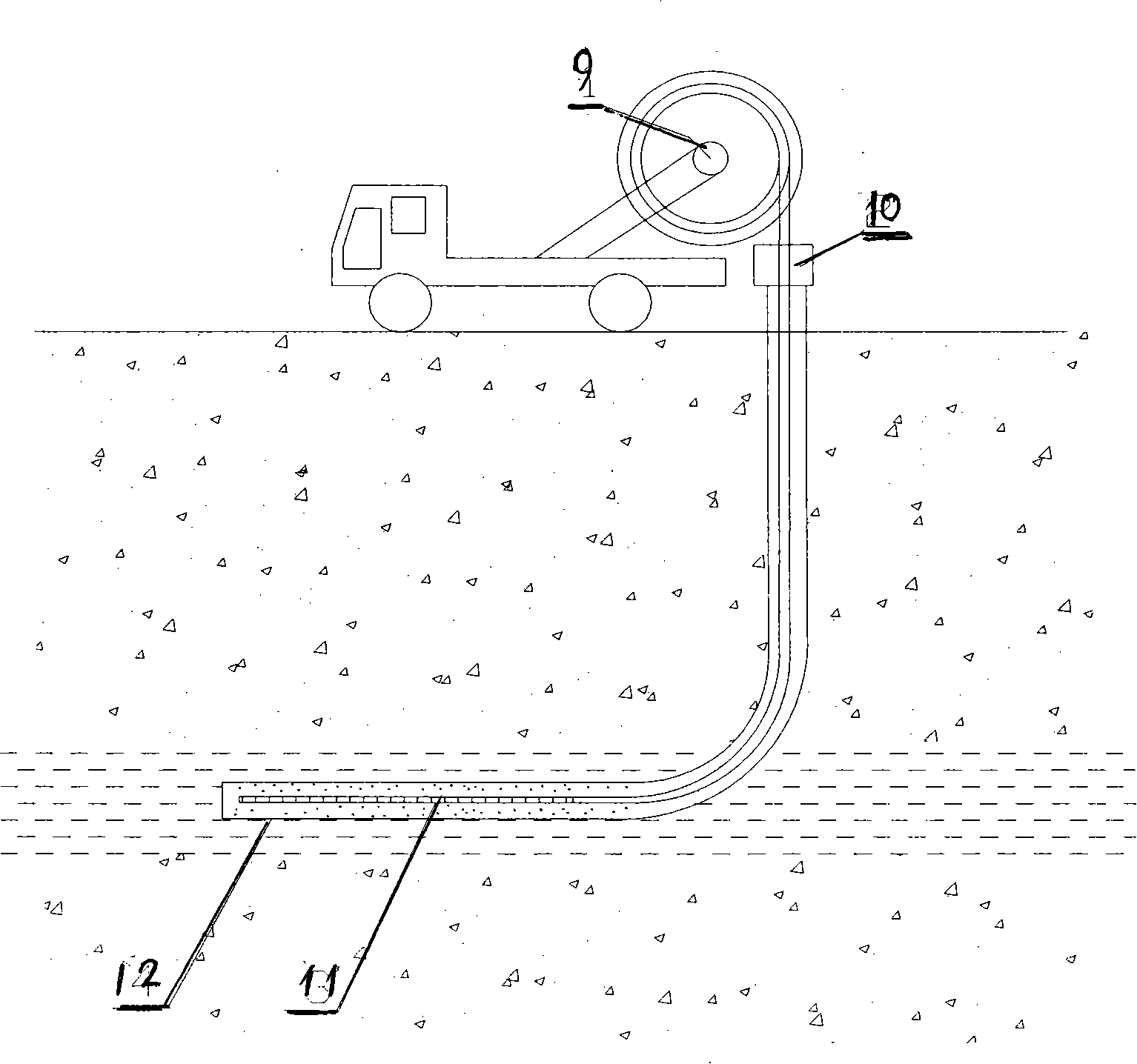

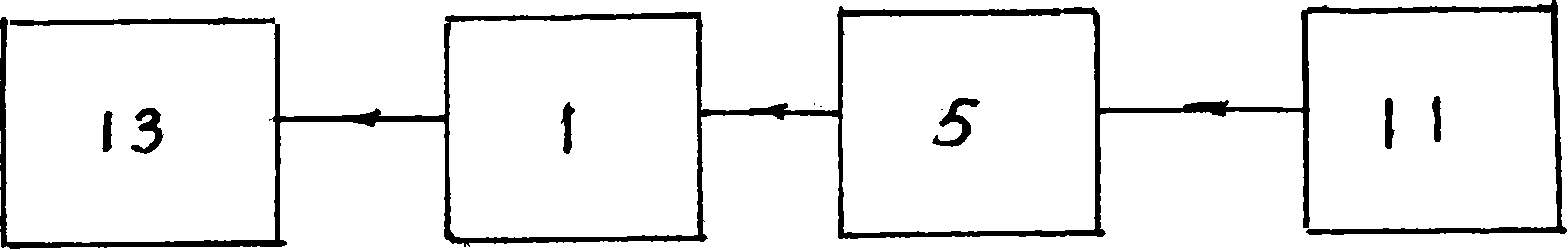

[0017] exist figure 2 In the test method, the high temperature and high pressure test optical fiber 11 is lowered into the perforated section 12 of the oil layer in the horizontal well with the high temperature and high pressure test wellhead sealer 10 by using the special optical cable equipment 9 to perform temperature and pressure tests.

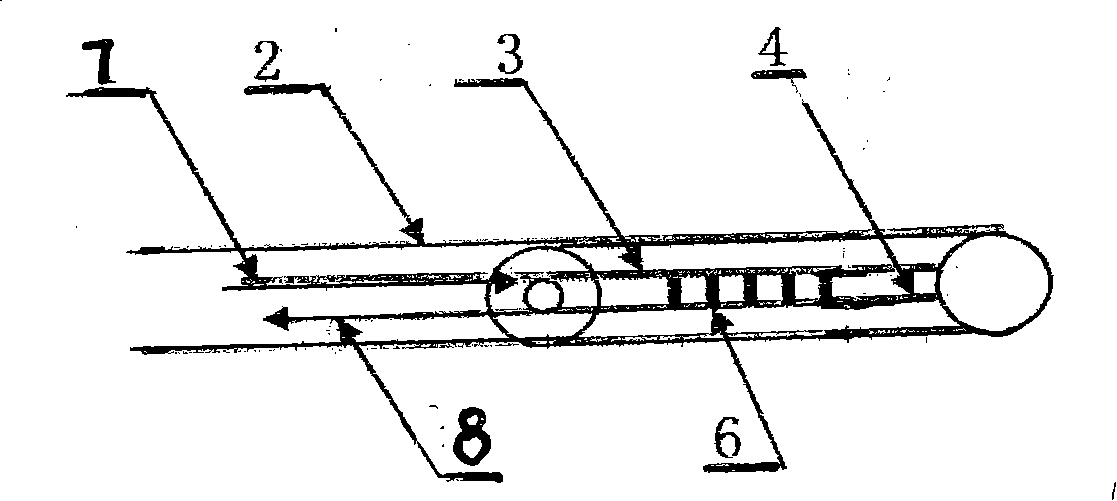

[0018] exist figure 1 Among them, the test optical fiber 11 is composed of the core 4 in the outer shell 2, the outer shell is a hollow tube made of 1cr18ni9ti, stainless steel material, and the core 4 in the circular tube has a certain length. Thin wires made of germanium, boron, and silicon dioxide are provided with ultraviolet gratings 6 parallel to each other on equal sections of thin wire cross sections, and polyene argon ammonia is installed in the annular chamber between the shell l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com