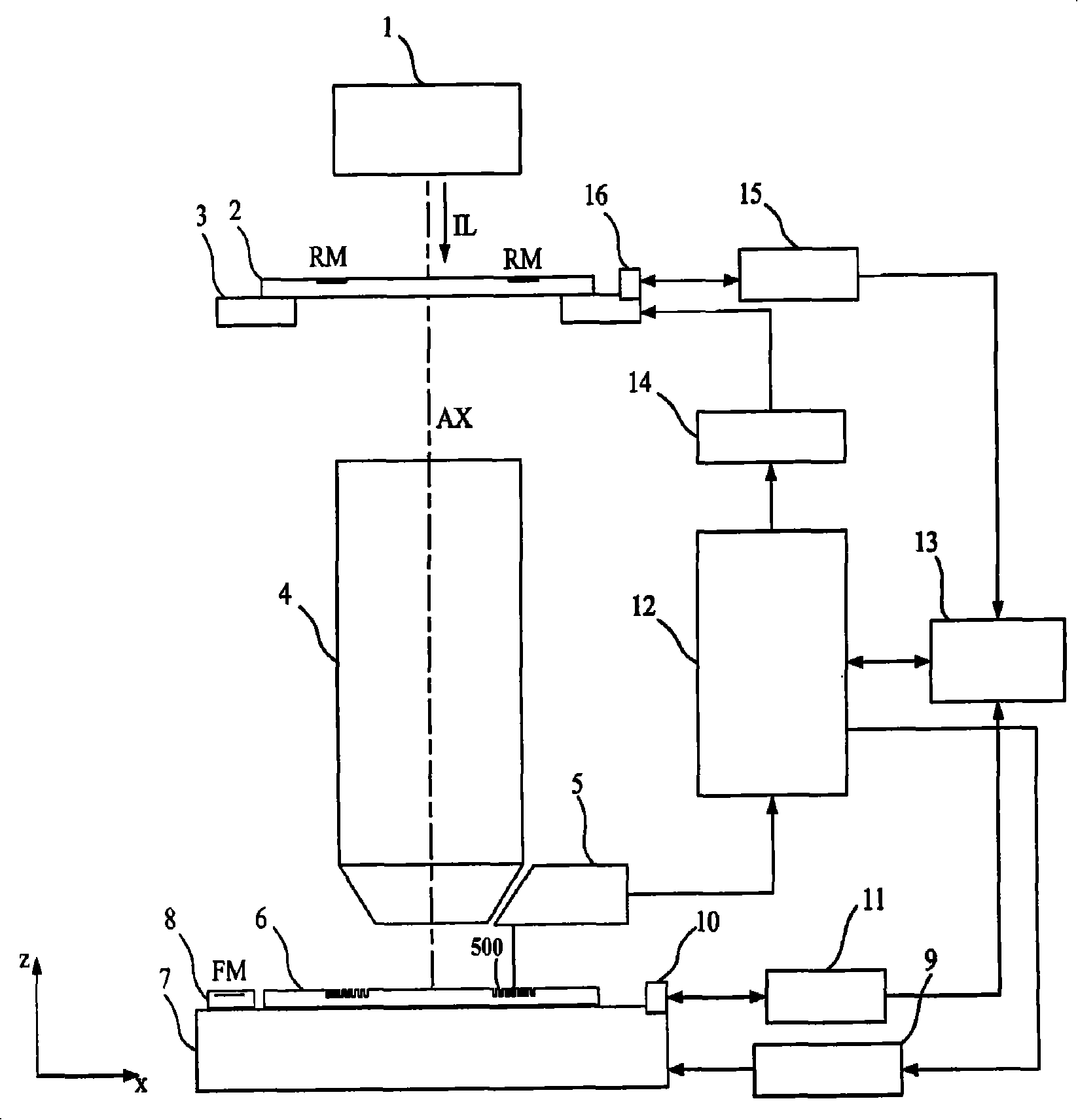

Aligning system, mark, method for lithographic device and lithographic device thereof

A technology for alignment marks and alignment systems, applied in microlithography exposure equipment, photolithography exposure devices, optics, etc., to improve energy utilization, reduce alignment position errors, improve alignment signal strength and detect The effect of the dynamic range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

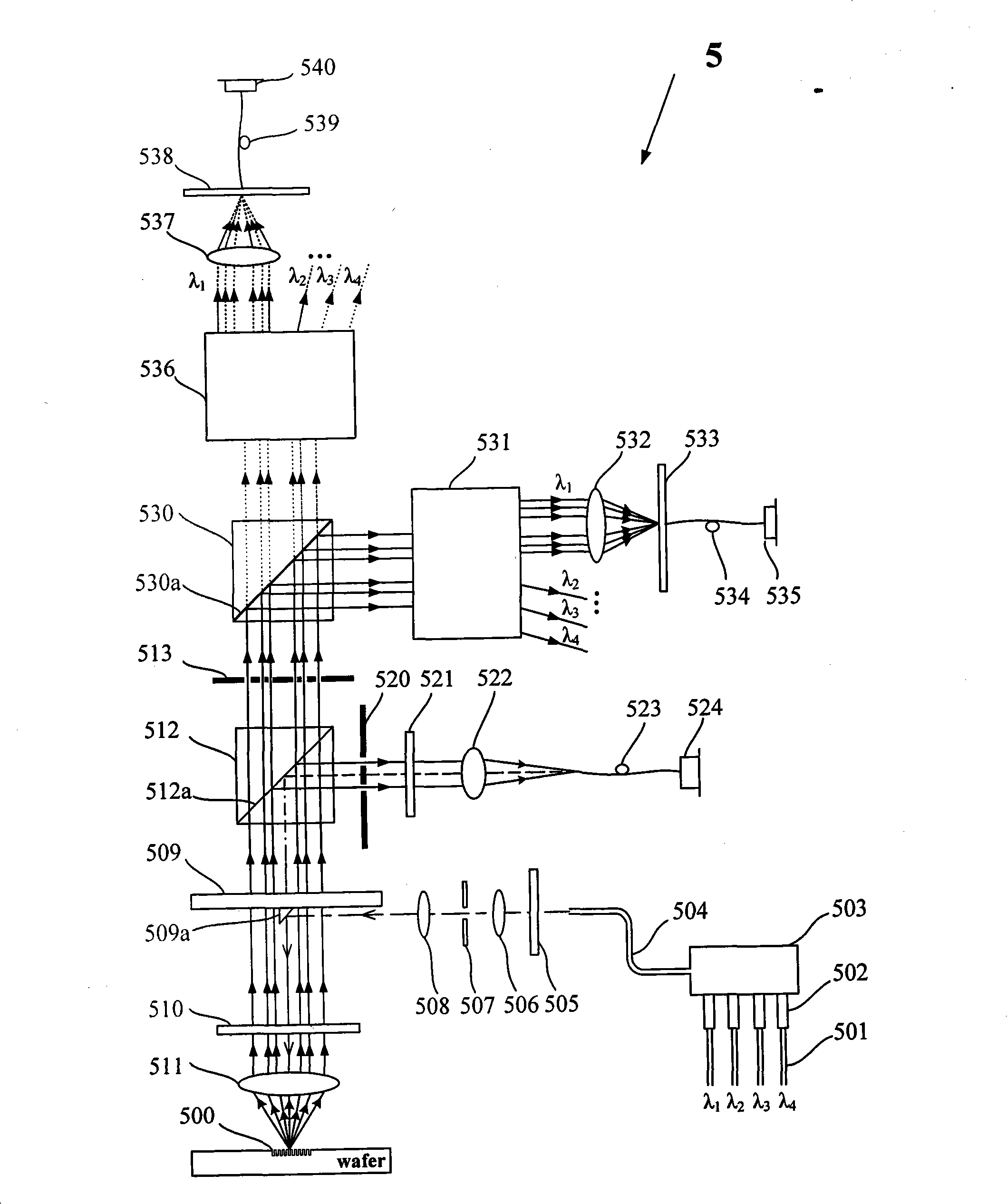

[0044] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

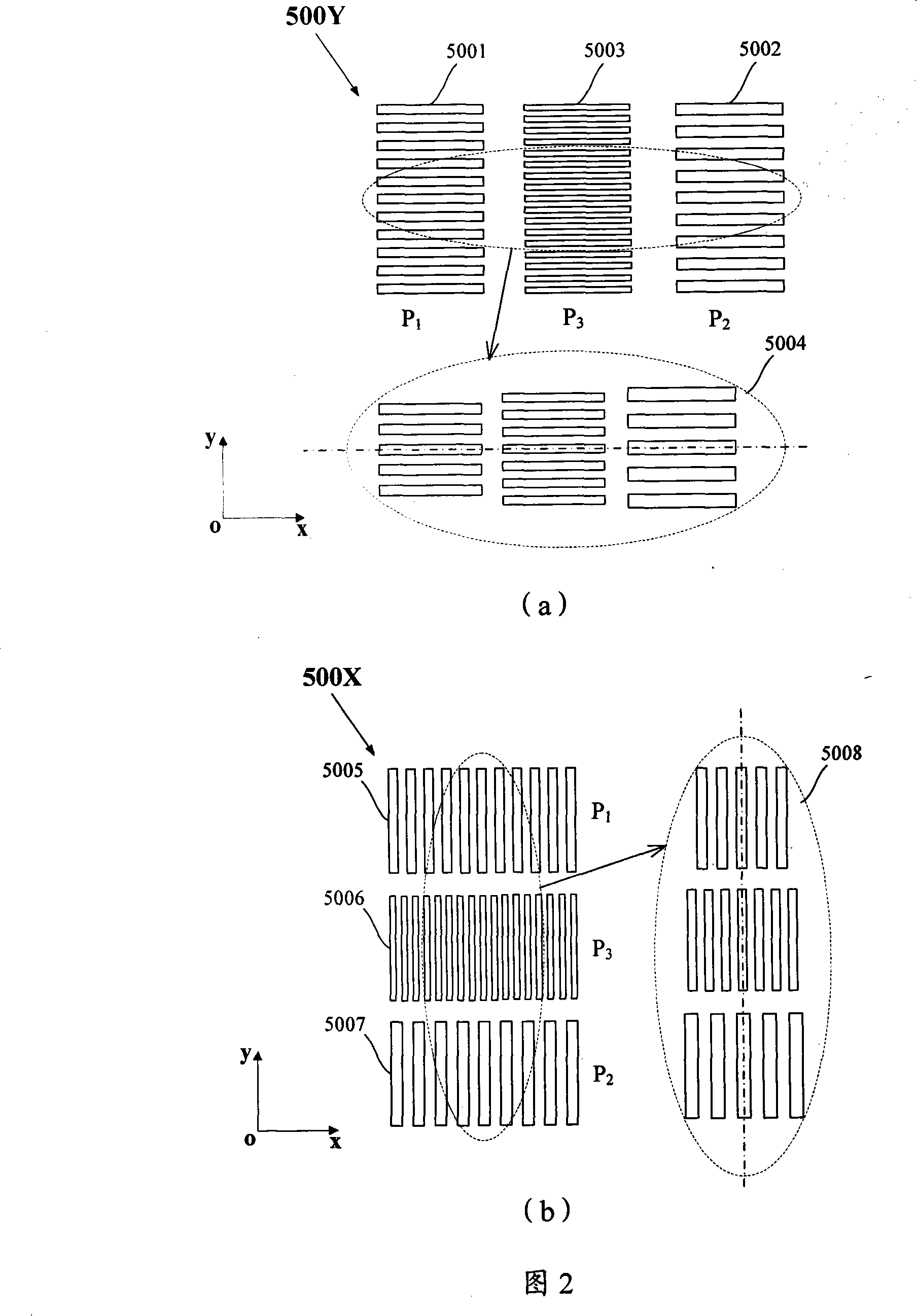

[0045] Figure 10 It shows the structure schematic diagram of the alignment mark and reference grating in the prior art. The wedge array or wedge plate group is used to realize the corresponding overlap and coherence of the positive and negative sub-spots of the multi-level diffracted light of the alignment mark, and at the same time, the diffraction at each level The deflection of the light beam through the wedge array or the wedge plate group makes the grating images of the alignment mark X8.0 for x-direction alignment arranged and imaged along the y-direction on the image plane; for y-direction alignment The grating images of all levels of grating Y8.0 are arranged and imaged along the x direction on the image plane, which avoids the situation that the grating images of different periods scan a reference grating at the same time when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com