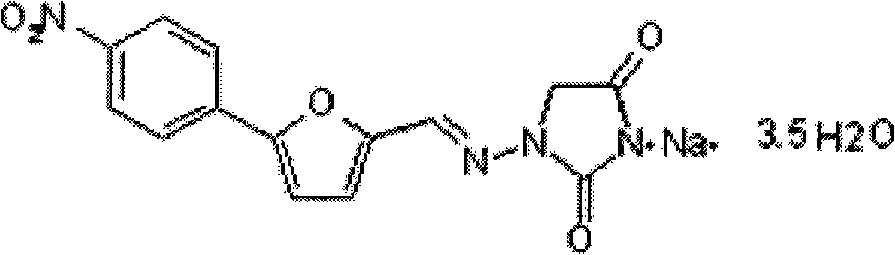

Freeze-dried powder needle preparations taking dantrolene sodium as activity component and preparation technique thereof

A technology of freeze-dried powder injection and dantrolene sodium, which is applied in the field of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

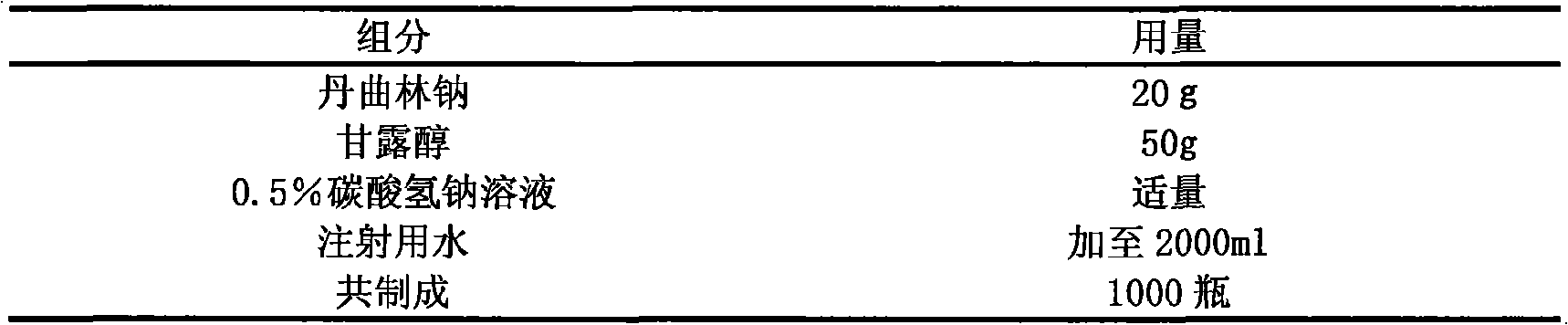

[0019] Embodiment 1 dantrolene sodium freeze-dried powder injection

[0020] prescription:

[0021]

[0022] Preparation:

[0023] Weigh the prescribed amount of dantrolene sodium and add 80% water for injection to dissolve it to make dantrolene sodium solution, add the prescribed amount of mannitol, adjust the pH value from 9.0 to 10.5, heat the liquid to about 60°C, Add 0.1% active carbon for needles, stir for 30min, and then adopt 0.22 μm microporous membrane fine filtration after filtering and decarbonizing. After the intermediate is tested and qualified, it is aseptically filled in a 5ml vial (theoretical amount of each bottle is 2ml). The liquid medicine is placed in a freeze-drying box and frozen for 4 hours to lower the temperature to about -45°C; for the first sublimation for 12 hours, the temperature rises to about -5°C; for the second sublimation for 4 hours, the temperature rises to 30°C, After pressing the cap, take it out, tie the cap, and you have it.

Embodiment 2

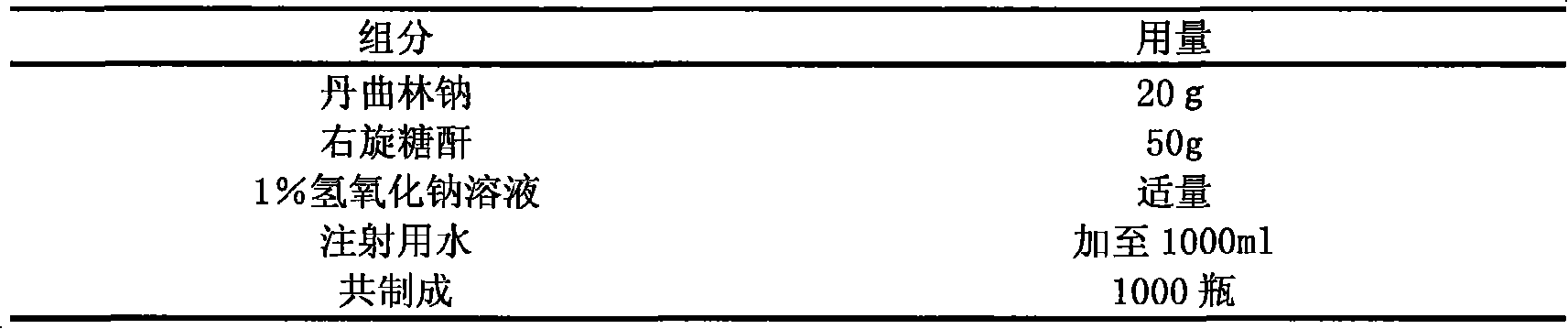

[0024] Embodiment 2: Dantrolene sodium freeze-dried powder injection

[0025] prescription:

[0026]

[0027] Preparation:

[0028] Weigh the prescribed amount of dantrolene sodium and add it to 80% water for injection heated to about 60°C to dissolve, then add the prescribed amount of dextran to adjust the pH value from 9.0 to 10.5, add 0.1% activated carbon for needles according to the prepared amount, keep warm and stir for 30 minutes, Filtration, decarbonization, and fine filtration with a 0.22 μm microporous membrane. After the intermediate is qualified, it is aseptically filled in a 2.7ml vial (theoretical amount of each bottle is 1ml), and the medicinal solution is placed in a freeze-drying box. Freeze for 3 hours to lower the temperature to about -45°C; for the first sublimation for 8 hours, the temperature rises to about -5°C; Instantly.

Embodiment 3

[0029] Embodiment 3: Dantrolene sodium freeze-dried powder injection

[0030] prescription:

[0031]

[0032] Preparation:

[0033] Weigh the prescribed amount of dantrolene sodium and add it to 80% water for injection heated to about 60°C to dissolve, then add the prescribed amount of glycine, sodium metabisulfite, sodium calcium edetate, stir and dissolve, adjust the pH value to 9.0-10.5, Add 0.1% activated carbon for needles according to the prepared amount, heat and stir for 30min, filter, decarbonize, and then finely filter with a 0.22 μm microporous membrane. After the intermediate is qualified, it is aseptically filled in a 5ml vial (theoretical 2ml), put the drug solution in a freeze-drying box, freeze for 3 hours, and make the temperature drop to about -45°C; the first sublimation takes 14-16 hours, and the temperature rises to about -5°C; the second sublimation is 4-6 After 1 hour, the temperature rises to 30°C, vacuum-press the lid, take it out, tie the lid, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com