Electro spinning method for preparing orientation arranged polymer spiral nano-fibre and equipment thereof

A technology of directional arrangement and polymer, which is applied in fiber processing, textile and paper making, filament/thread forming, etc., can solve the problems of inability to effectively control helical fibers and difficult to control the directional arrangement of helical fibers, and the method is simple and easy to implement, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

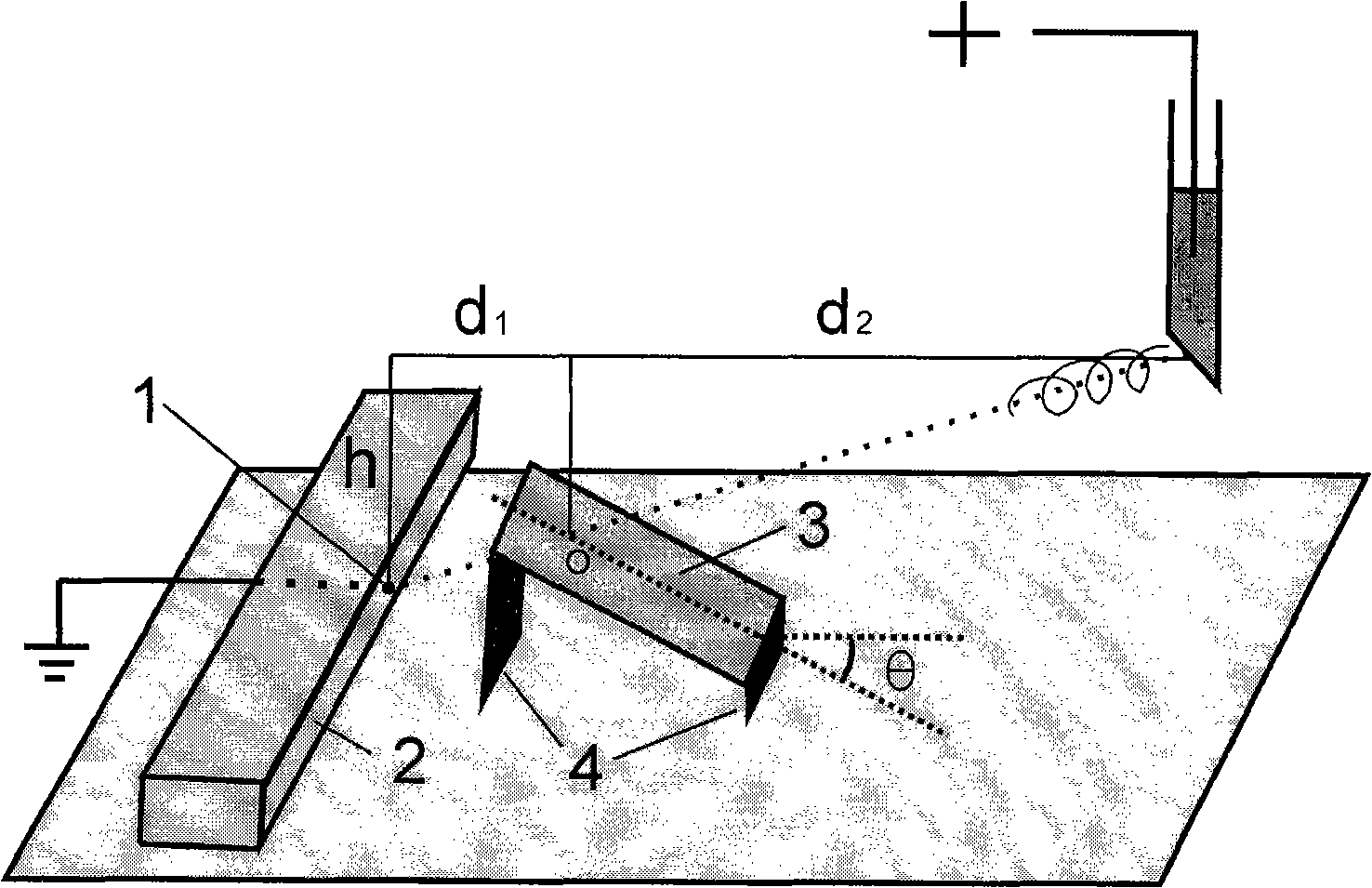

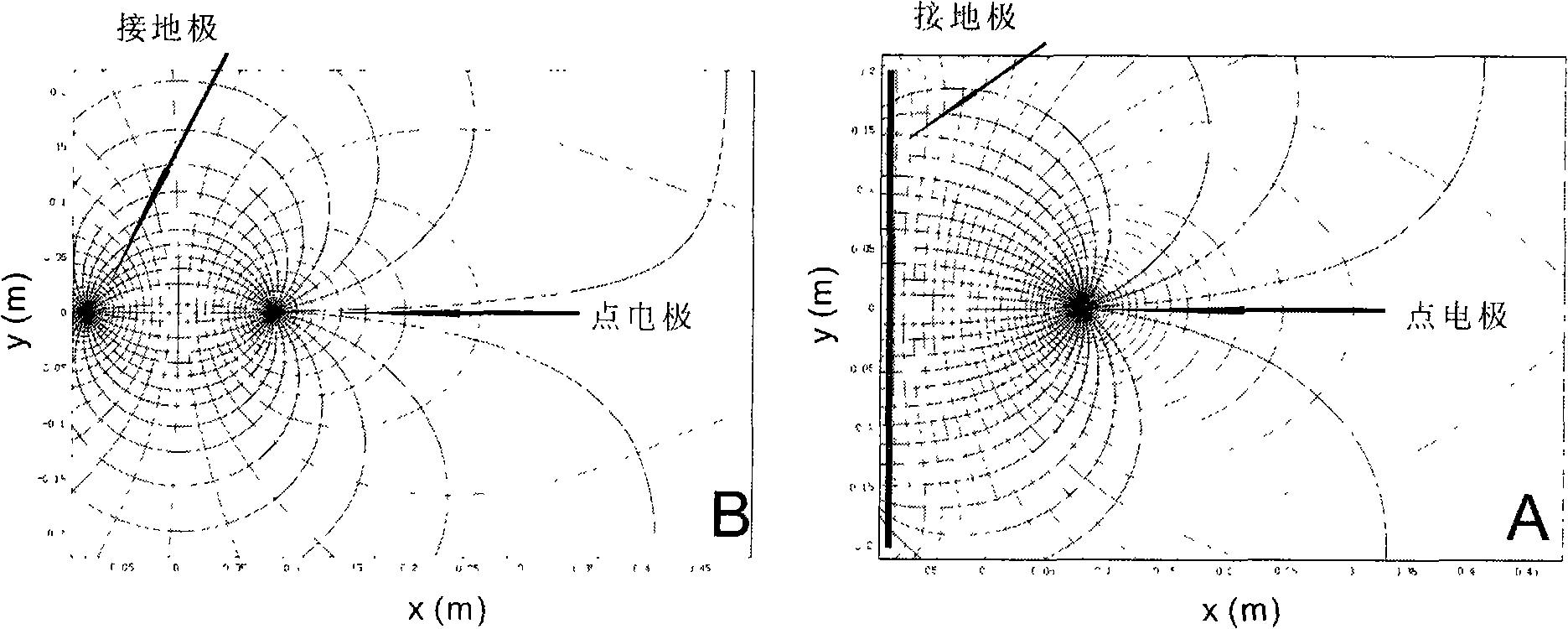

Method used

Image

Examples

Embodiment 1

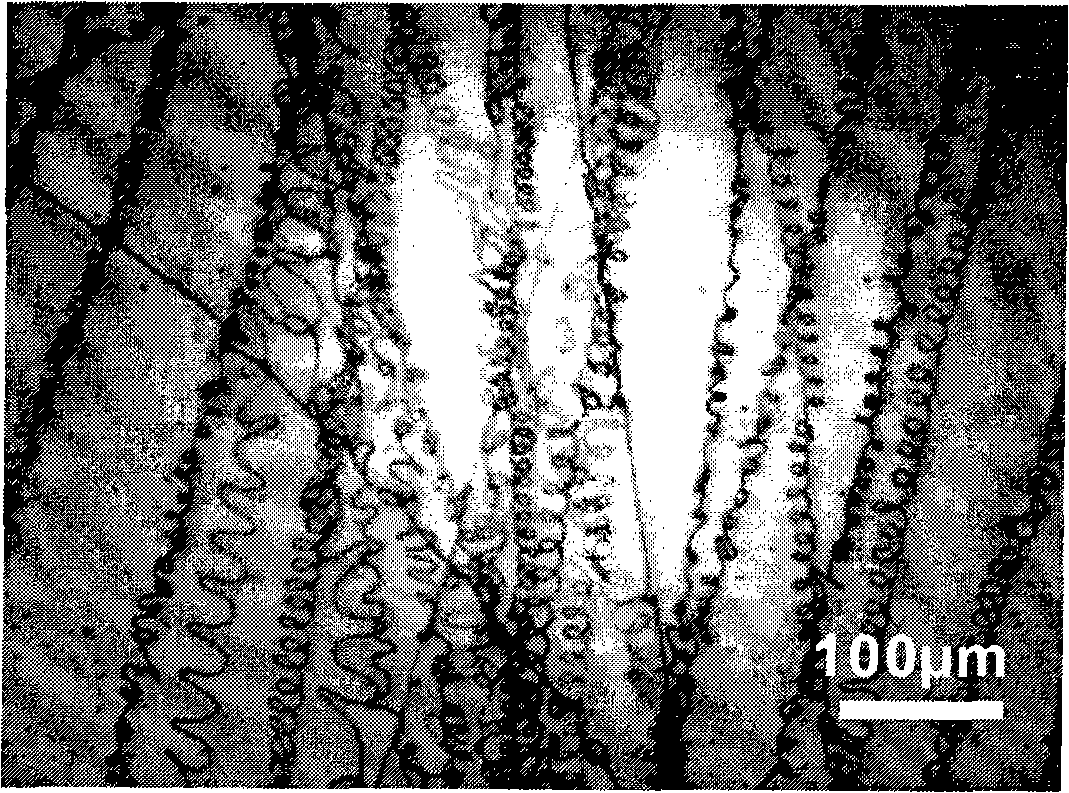

[0016] Preparation of aligned PCL nanohelical fibers. Dissolve PCL in a 1: 1 mixed solvent of tetrahydrofuran (THF) and DMF (dimethylformamide), the concentration range is 4.7-10% (percentage by weight), and spin after 24 hours with a magnetic stirrer, and the voltage is 18kV. image 3 is an optical micrograph of a helical fiber prepared with a 5.8% PCL solution. The collection plate is located as follows: d 1 = 1cm, d 2= 11 cm, θ = 20°C, h = 3.5 cm. It can be seen that aligned helical fibers are obtained. Helical fibers with different diameters can be obtained by adjusting the concentration of the solution. Figure 4 The relationship curve of the helical diameter changing with the concentration is shown, it can be seen that the helical diameter first increases and then decreases with the increase of the concentration, and the helical fiber with a diameter in the range of 6.9-15.9 μm can be obtained in the concentration range of 4.7-10%. Especially when the diameter reac...

Embodiment 2

[0018] Preparation of PAN oriented nanohelical fibers. Dissolve PAN in DMF at a concentration of 10%, and spin after magnetic stirring for 12 hours. The spinning voltage is 23kV. The collection plate is located as follows: d 1 = 1cm, d 2 =8cm, θ=15°C, h=3cm. Image 6 It is a photograph of the prepared PAN helical fibers, it can be seen that aligned PAN helical nanofibers have been obtained. It is shown that this method is generally applicable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com