Gallium-nitride-based compound semiconductor light emitting element and its manufacturing method

A technology of light-emitting devices and manufacturing methods, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as production efficiency decline, troublesome processes, complexity, etc., achieve high output power, suppress interference effects, and improve optical efficiency. focus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

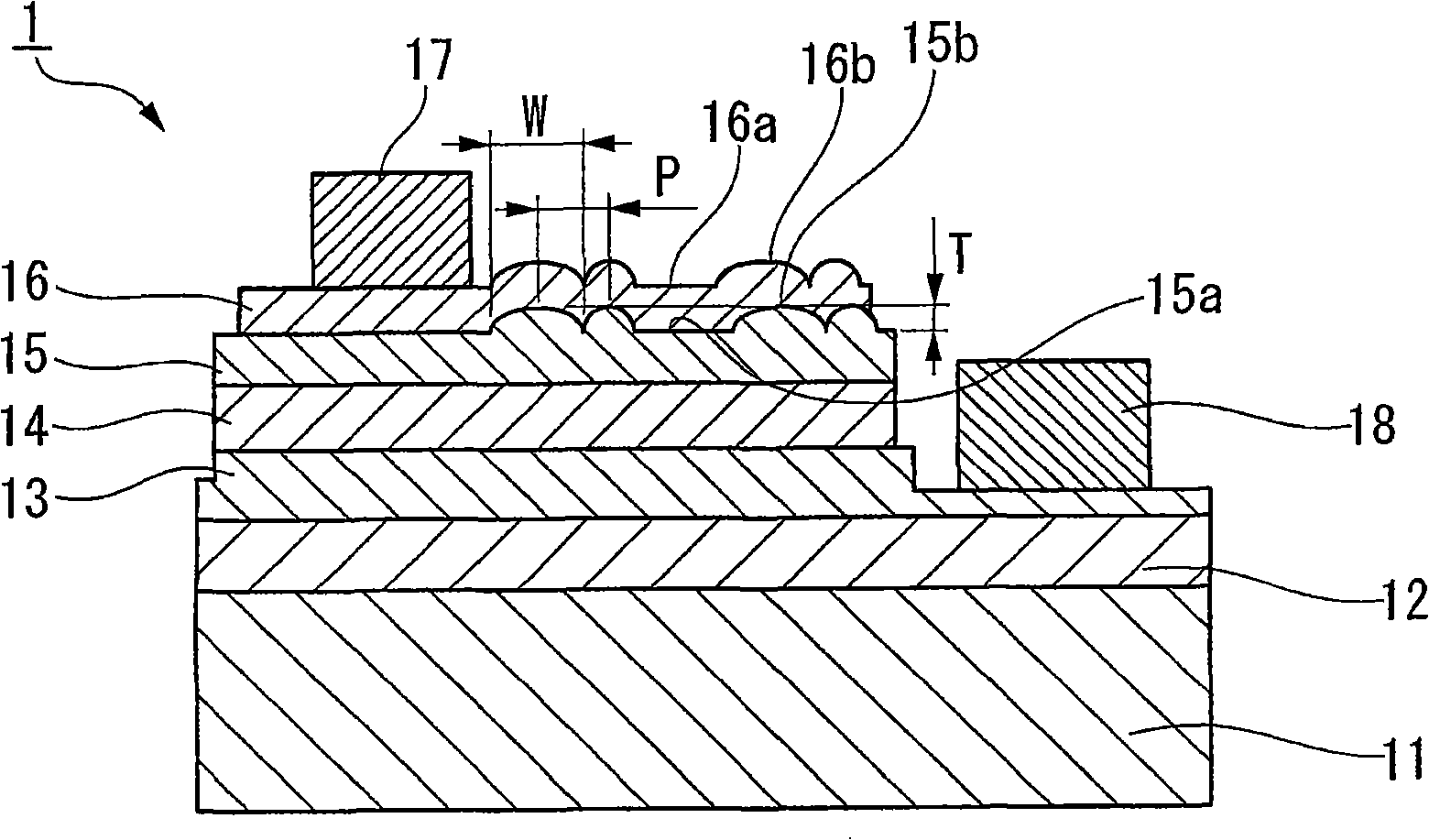

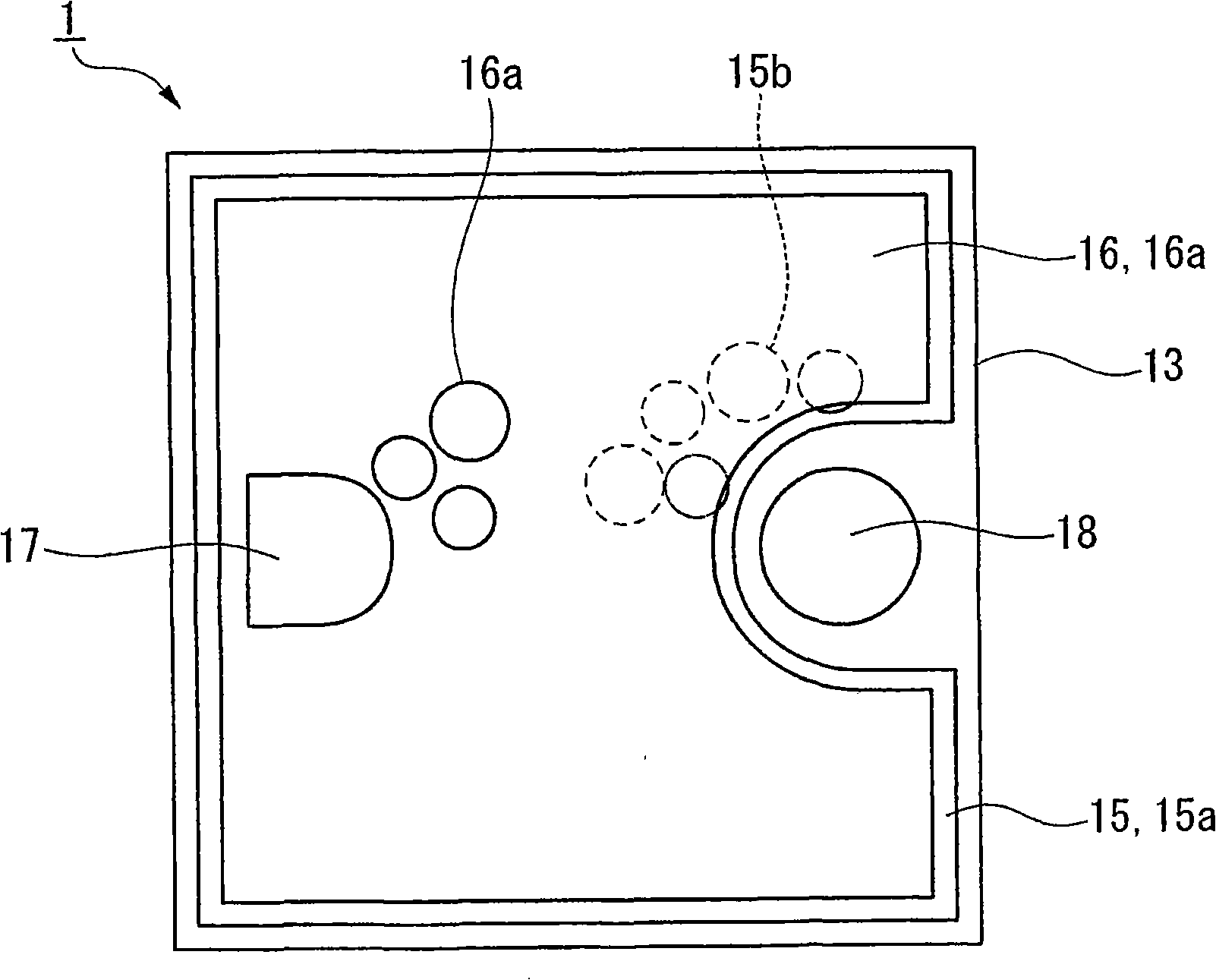

[0136] figure 1 A schematic diagram showing a cross-section of a gallium nitride-based compound semiconductor light-emitting device fabricated as an example, while figure 2 A schematic plan view is shown.

[0137] (Manufacture of Gallium Nitride-based Compound Semiconductor Light-Emitting Devices)

[0138] A gallium nitride-based compound semiconductor layer is laminated on a substrate 1 made of sapphire through a buffer layer 12 made of AlN. The gallium nitride-based compound semiconductor layer includes: an n-type semiconductor layer in which an 8-μm-thick lower layer made of undoped GaN, a 2-μm-thick Ge-doped n-type GaN contact layer, and a 0.02-μm-thick n-type GaN contact layer are sequentially stacked. In 0.1 Ga 0.9 N cladding layer; five layers of 16nm thick Si-doped GaN barrier layer and 2.5nm thick In 0.06 Ga 0.94 N well layer, and finally, light emitting layer 14 having a multi-quantum well structure provided with a barrier layer; and p-type Al doped with Mg by...

example 2-10

[0163] Materials used for the metal fine particles are shown in Table 1. A point under which heat treatment was performed at the heating temperature shown in Table 1 was excluded, and a gallium nitride-based compound semiconductor light-emitting device was produced similarly to Example 1.

example 11

[0165] A spot under which an uneven pattern consisting of protrusions was not formed on the surface of the p-type semiconductor layer was excluded, and a gallium nitride-based compound semiconductor light-emitting device was fabricated similarly to Example 1.

[0166] Examples 12 to 13

[0167] Points under which the average value and standard deviation of the protrusions on the surface of the p-type semiconductor layer became the same as the values shown in Table 1 were excluded, and a gallium nitride-based compound semiconductor was produced similarly to Example 1 device.

[0168] Table 1 shows a list of conditions of the uneven shape, protrusion distance, and device characteristics of Examples 1 to 13 described above.

[0169]

[0170] From the evaluation results of the device characteristics shown in Table 1, the average distance of the protrusions of the gallium nitride-based compound semiconductor light-emitting devices of Examples 1 to 10 in which a disordered une...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com