Curable silicone composition and optical semiconductor device

A silicone composition and silicon atom bonding technology, applied in semiconductor devices, semiconductor/solid-state device parts, electrical solid-state devices, etc., can solve problems such as insufficient light extraction efficiency and changes in light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

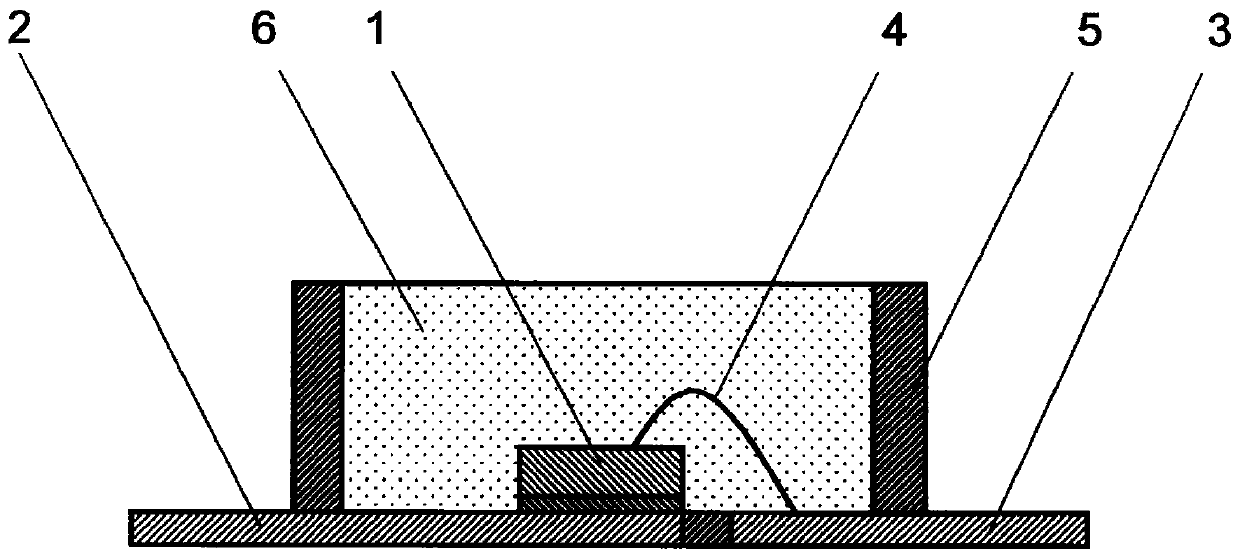

Image

Examples

example

[0090] The curable silicone composition and the optical semiconductor device of the present invention are described in more detail below by means of examples and comparative examples. It should be noted that the viscosity refers to the value at 25°C. The following components were used to prepare the curable silicone compositions of the Examples and Comparative Examples. In the formula, Me, Ph, Vi, and Ep represent a methyl group, a phenyl group, a vinyl group, and a 3-glycidoxypropyl group, respectively.

[0091] The following components were used as component (A). (a1) A methylphenylpolysiloxane having two molecular chain ends terminated by dimethylvinylsiloxy groups, which has the following average formula:

[0092] ViMe 2 SiO(MePhSiO) 23 SiMe 2 Vi

[0093] and the following average composition formula:

[0094] Me 1.08 Ph 0.92 Vi 0.08 SiO 0.96

[0095] Expressed (phenyl content = 44.2mol%)

[0096](a2) Dimethyldiphenylpolysiloxane having two molecular chain end...

example 1-6、 comparative example 1 and 2

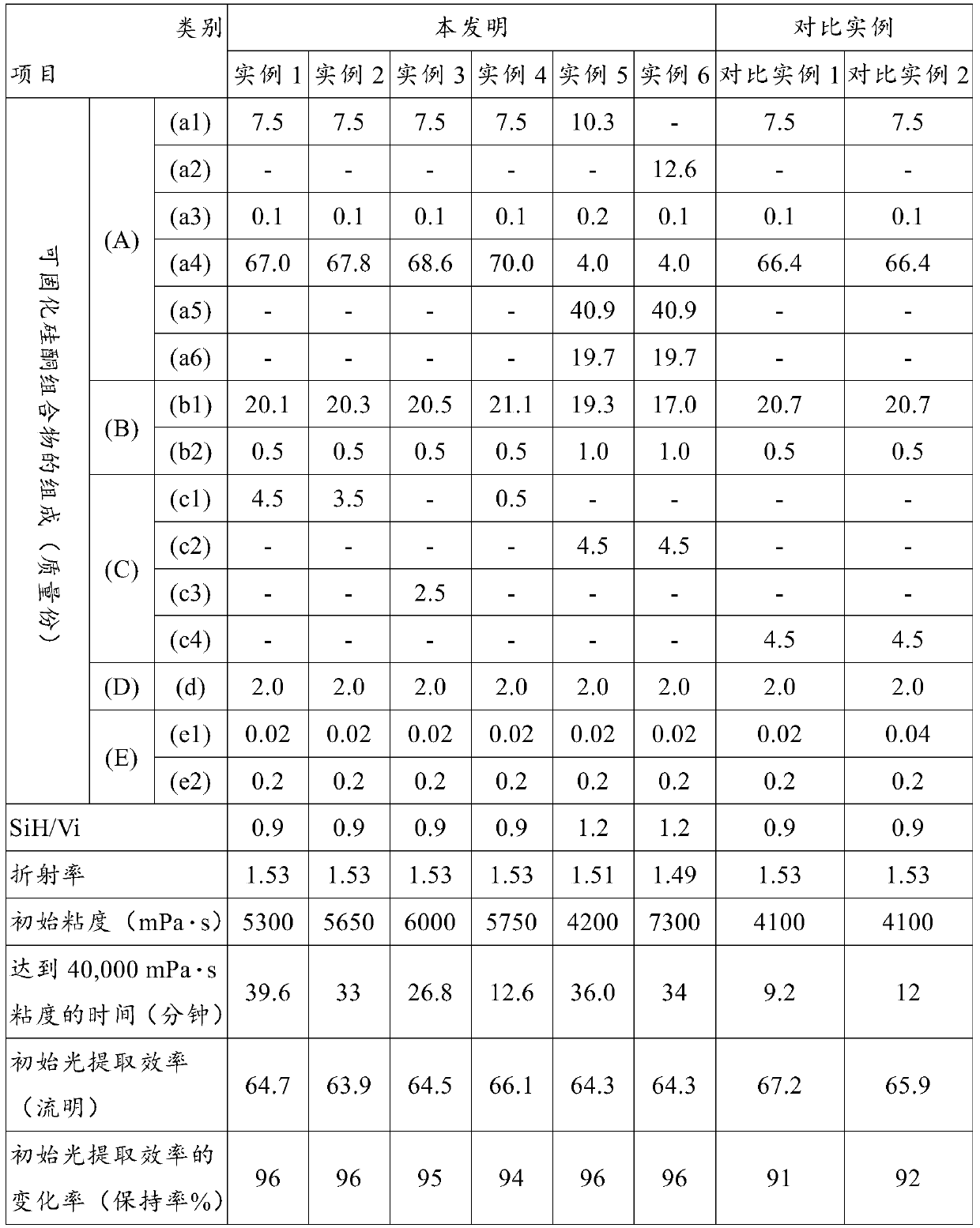

[0156] Curable silicone compositions were prepared using the compositions shown in Table 1. It should be noted that in Table 1, "SiH / Vi" represents the sum of moles of silicon atom-bonded hydrogen atoms in component (B) per 1 mole of the sum of vinyl groups of component (A). The characteristics of the curable silicone compositions and the characteristics of optical semiconductor devices manufactured using these compositions are also shown in Table 1.

[0157] [Table 1]

[0158]

[0159] *Component (c4) used in Comparative Examples 1 and 2 in the table does not have a siloxane unit represented by the formula: ViSiO 3 / 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com