Lubricant agent special for powder metallurgical stainless steel

A powder metallurgy and lubricant technology, which is applied in the field of powder metallurgy stainless steel special lubricant and powder metallurgy lubricant, can solve the problem of high addition amount, achieve the effect of prolonging service life, improving strength and surface finish, yield and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Product aspect ratio <1:1

[0016] Step 1. Prepare lubricant

[0017] Take 50kg of -45um Ake wax, 30kg of -45um stearic acid, and 20kg of polyethylene vinyl acetate, and mix them evenly to prepare a lubricant.

[0018] Step 2. Production of powder metallurgy stainless steel products

[0019] Take 0.3kg of the lubricant prepared in step 1, add it to 99.7kg of powder metallurgy stainless steel powder, mix in a clean double cone mixer at a speed of 19r / min for 60min, and make powder according to the production process of ordinary powder metallurgy stainless steel parts Metallurgical stainless steel products.

Embodiment 2

[0020] Example 2: Product aspect ratio > 1:1

[0021] Step 1. Prepare lubricant

[0022] Take 50kg of -45um Ake wax, 30kg of -45um stearic acid, and 20kg of polyethylene vinyl acetate, and mix them evenly to prepare a lubricant.

[0023] Step 2. Production of powder metallurgy stainless steel products

[0024] Take 0.5kg of the lubricant prepared in step 1, add it to 99.5kg of powder metallurgy stainless steel powder, mix in a clean double cone mixer at a speed of 21r / min for 60min, and make powder according to the production process of ordinary powder metallurgy stainless steel parts Metallurgical stainless steel products.

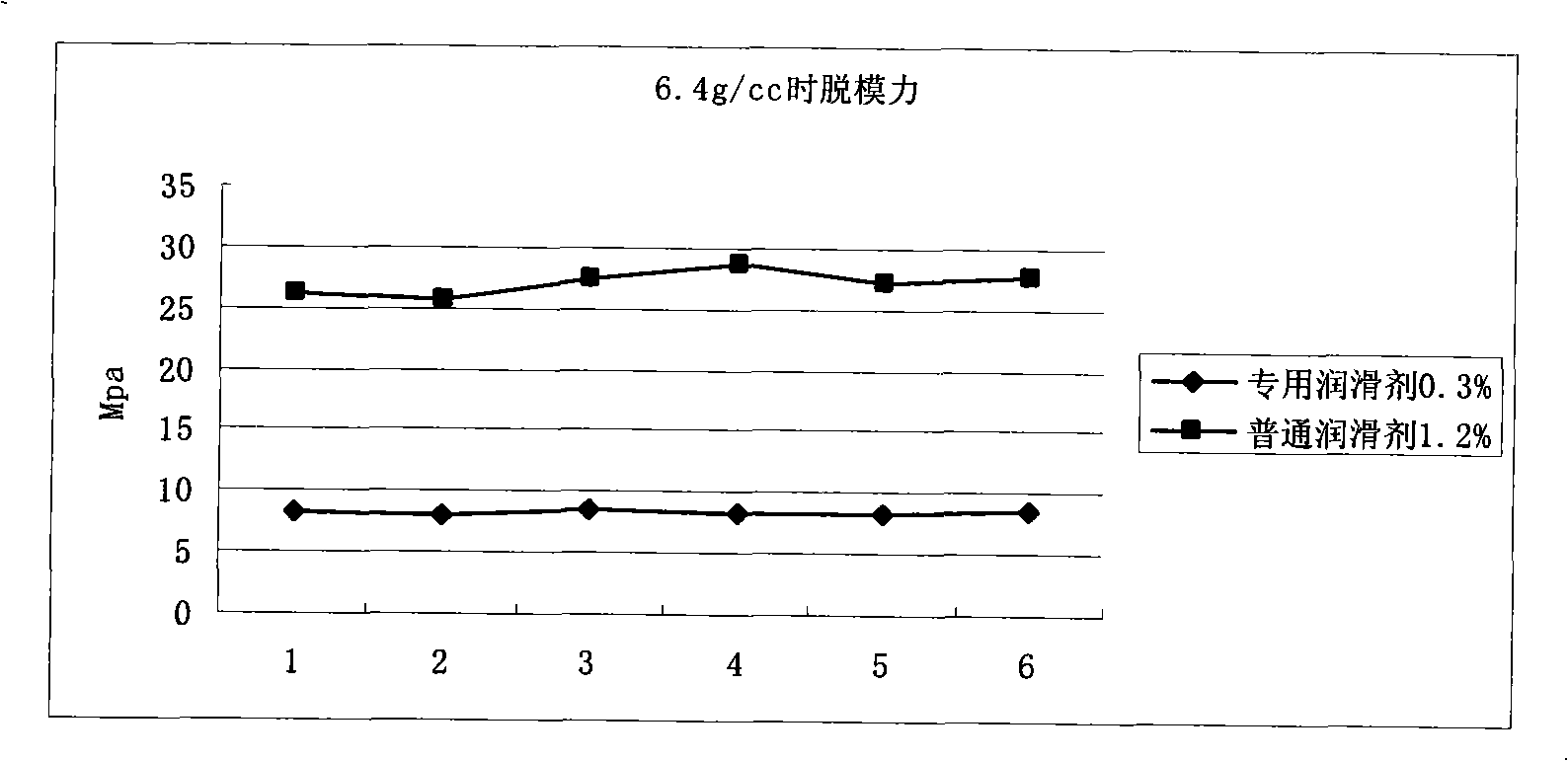

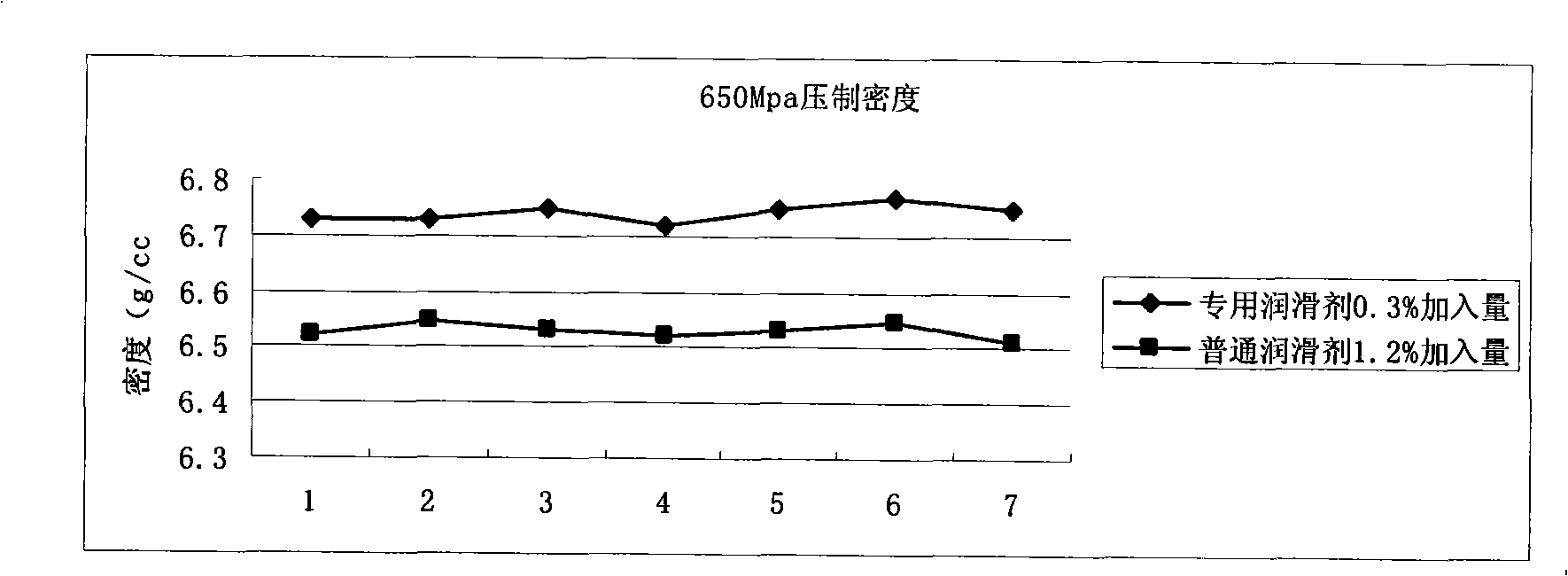

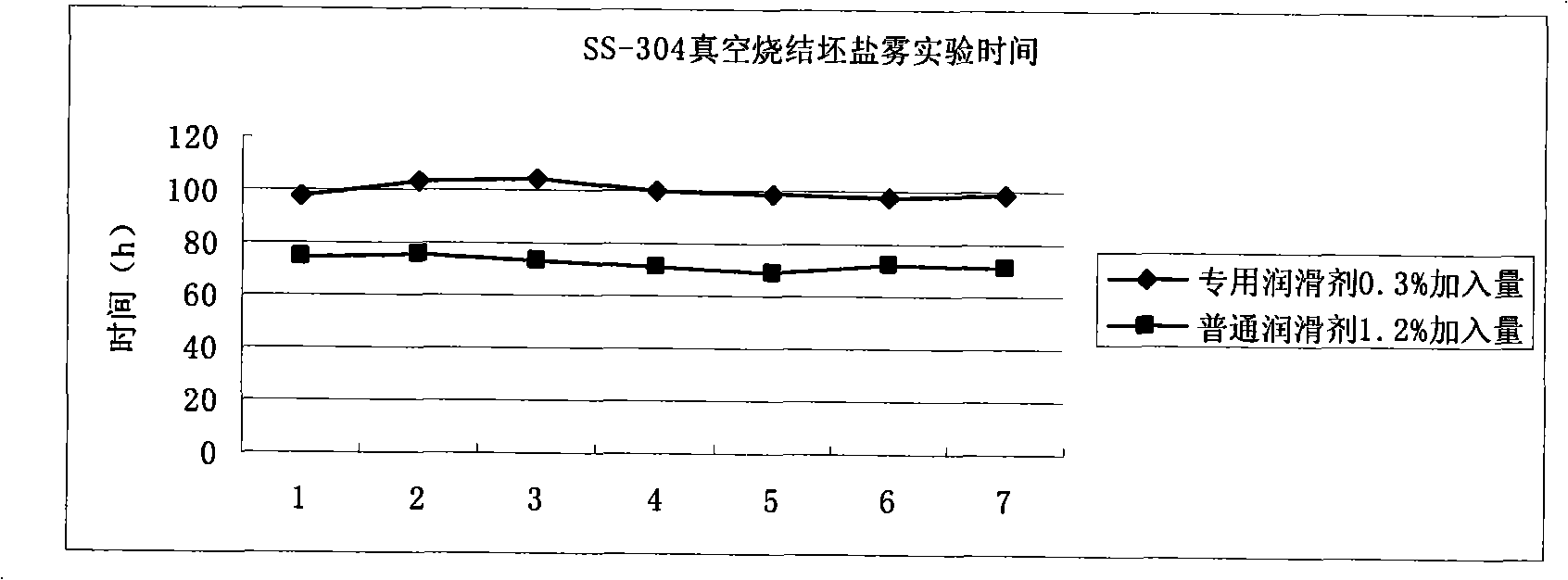

[0025] In the above figures, figure 1 It is a comparison chart of demoulding force when special lubricant of the present invention and common lubricant are 6.4g / cc; figure 2 It is a comparison chart of 650Mpa pressing density between the special lubricant of the present invention and the common lubricant; image 3 It is a comparison chart of the sal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com