Polyethylene pipeline weld joint ultrasonic detection dedicated transducer

An ultrasonic and polyethylene technology, applied in the field of ultrasonic detection, can solve problems such as limiting the distance of ultrasonic transmission, easy sticking, and personnel poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

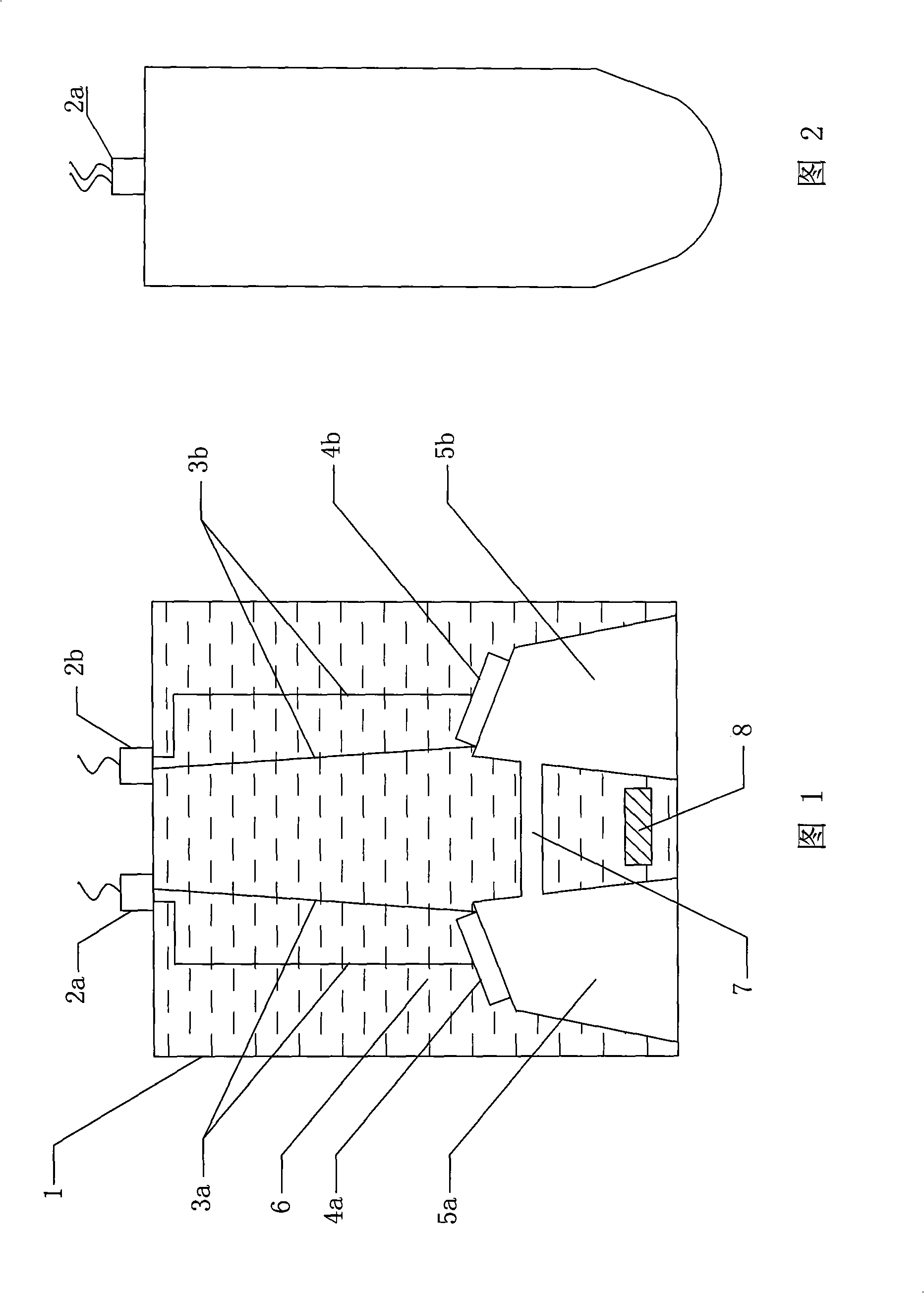

[0009] See Fig. 1, Fig. 2, the present invention comprises metal casing 1, signal transmitting terminal 2a and signal receiving terminal 2b, sound-absorbing material 6, piezoelectric chip, left delay block 5a, right delay block 5b, left delay block 5a, The right delay blocks 5b are connected by connecting ribs 7, the piezoelectric wafers 4a, 4b are mounted on the tops of the left delay block 5a and the right delay block 5b respectively, and the signal transmitting terminal 2a and the signal receiving terminal 2b are respectively connected to the pressure terminals on both sides. The electric chip 4a, 4b is connected, and under the connecting rib 7, a magnetic block 8 is arranged in the neutral position between the left delay block 5a and the right delay block 5b; the main materials of the sound-absorbing material 6 are epoxy resin and tungsten powder; The lower end of the device is a plane or an arc surface (arc surface in Fig. 2); the material of the magnetic block 8 is a mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com