Multiple aluminium wire surface plasma on-line processing method and device

A technology of surface plasma and plasma, which is applied in the direction of plasma, the device for coating liquid on the surface, and pretreatment of the surface, etc., can solve the problems that cannot meet the requirements of industrial production and product quality, and the adhesion of aluminum wires and insulating varnishes to copper Line difference, affect the quality of enamelled aluminum wire and other problems, to achieve the effect of eliminating micropores, improving insulation performance and saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

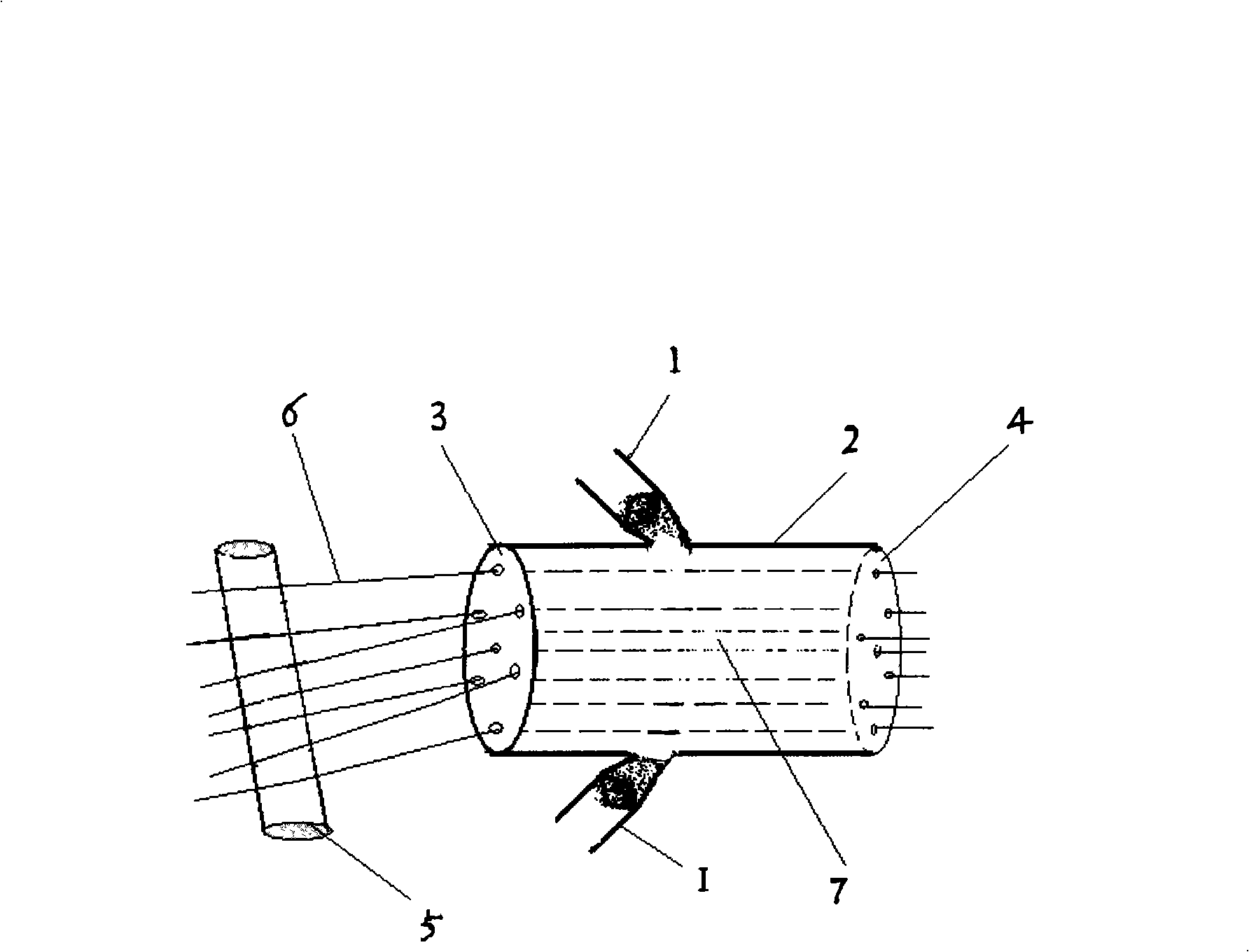

[0017] Multiple aluminum wire surface plasma on-line treatment device, in the production line of aluminum wire painting, firstly, the aluminum wire is preliminarily cleaned and heat-treated. Process, aluminum wire painting process; in the plasma surface treatment process, in order to improve the efficiency of plasma treatment of the surface of aluminum wires, the aluminum wires 6 scattered in the plane on the wire arranging wheel 5 are gathered into a compact bundle of aluminum wires 6 , the aluminum wire 6 passes through the conduit 2, the two ends of the conduit 2 are respectively provided with an incoming wire screen 3 and an outgoing wire screen 4, and there are openings on the incoming wire screen 3 and the outgoing wire screen 4, and the aluminum wire 6 is connected to Enter the wire conduit 2, come out from the outlet screen 4, and set a plurality of plasma generators 1. This plasma generator is a cold arc plasma generator. When a certain flow rate of compressed air flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com