Preparation of high photocatalysis activity titanium dioxide nano-stick by non-hydrosol-gel method and surface thereof functionalization

A technology of titanium dioxide and nanorods, applied in the field of nanomaterials, can solve problems such as difficult expansion of production scale, limited reaction output, complicated process, etc., and achieve the effect of convenient large-scale production, low cost and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

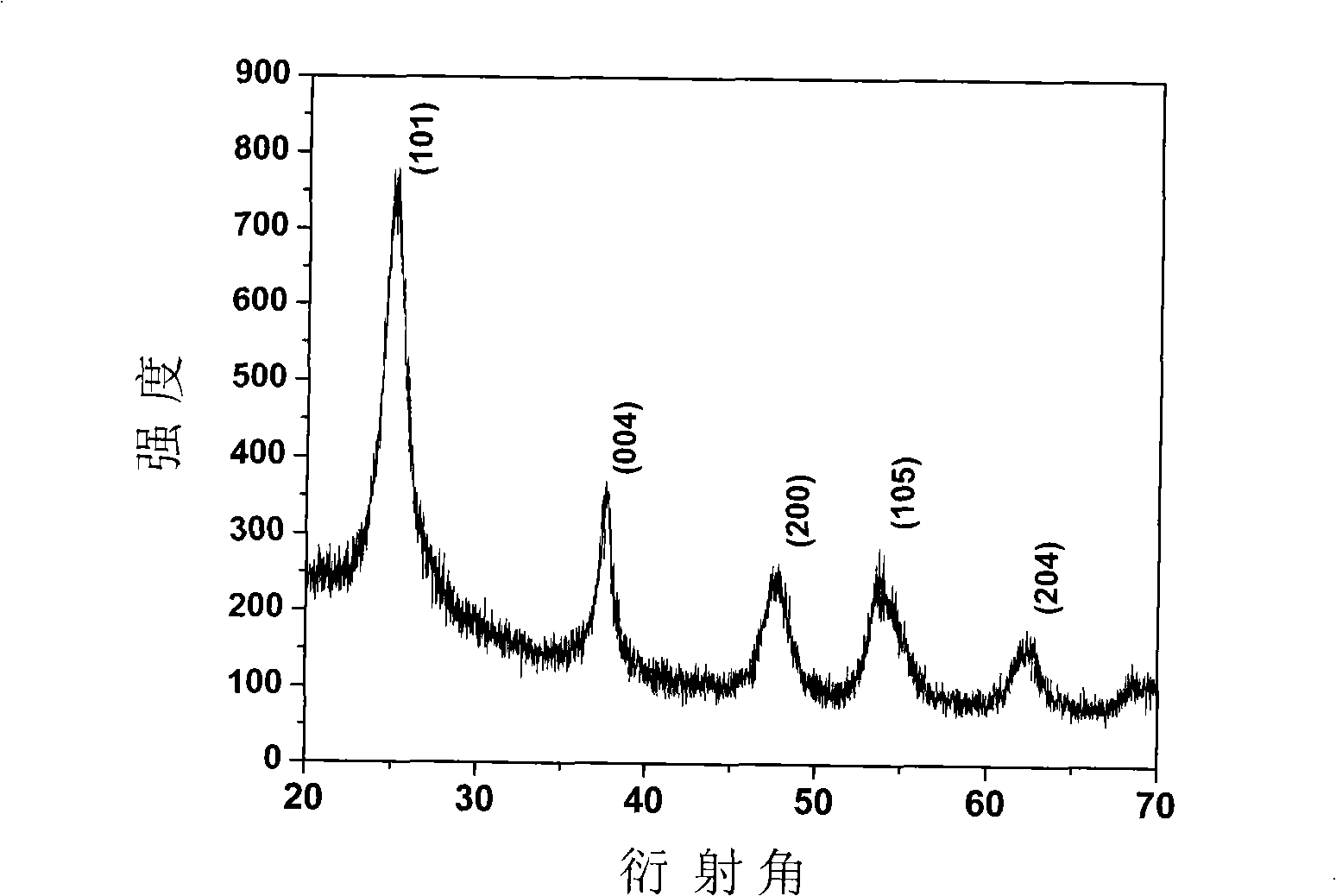

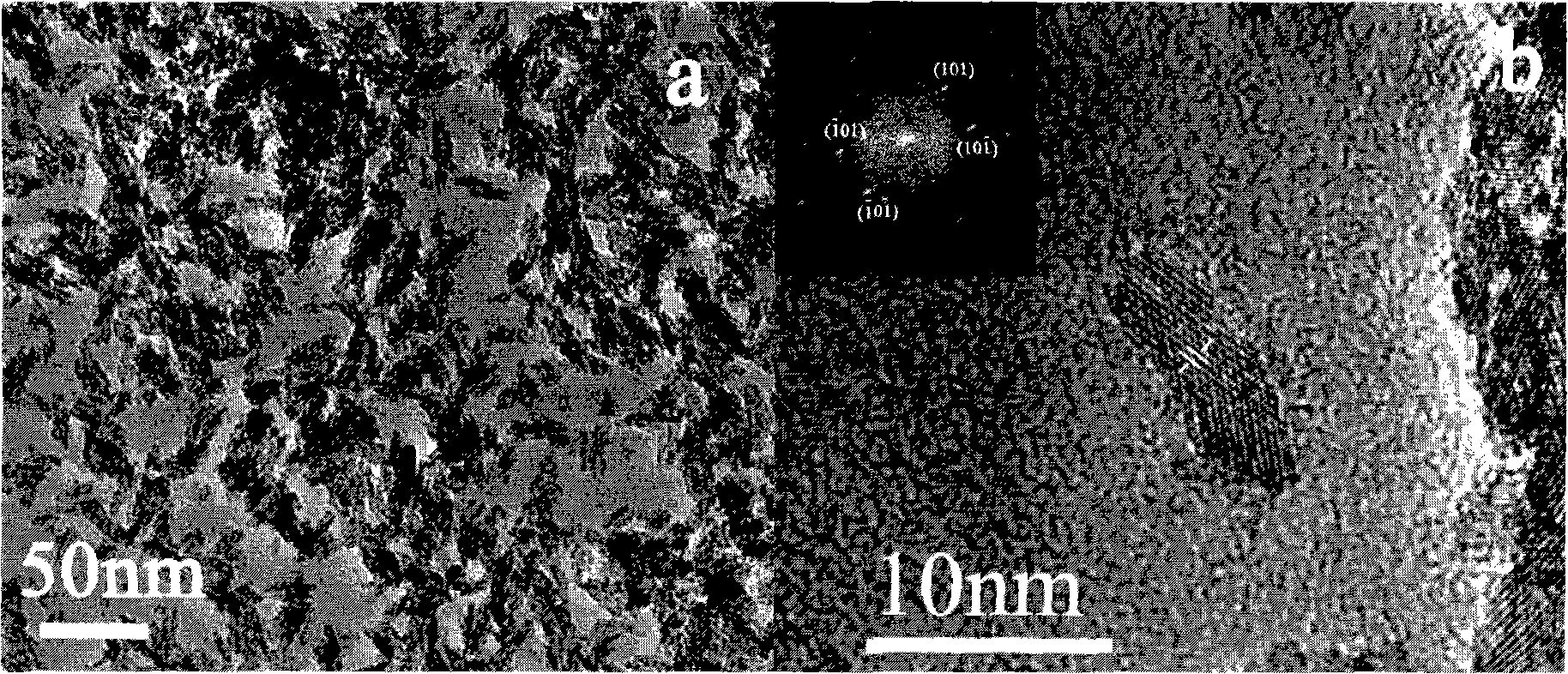

[0021] Under vigorous stirring, titanium tetrachloride was gradually added to benzyl alcohol to form a solution, in which the titanium content was 0.4 mol / liter, and then the white emulsion was left to stand at 80°C for 70 hours to completely hydrolyze the titanium dioxide, and the reaction ended A white precipitate was obtained by centrifugation, washed with chloroform, and then dried at 50° C. to obtain white anatase titanium dioxide nanorods.

Embodiment 2

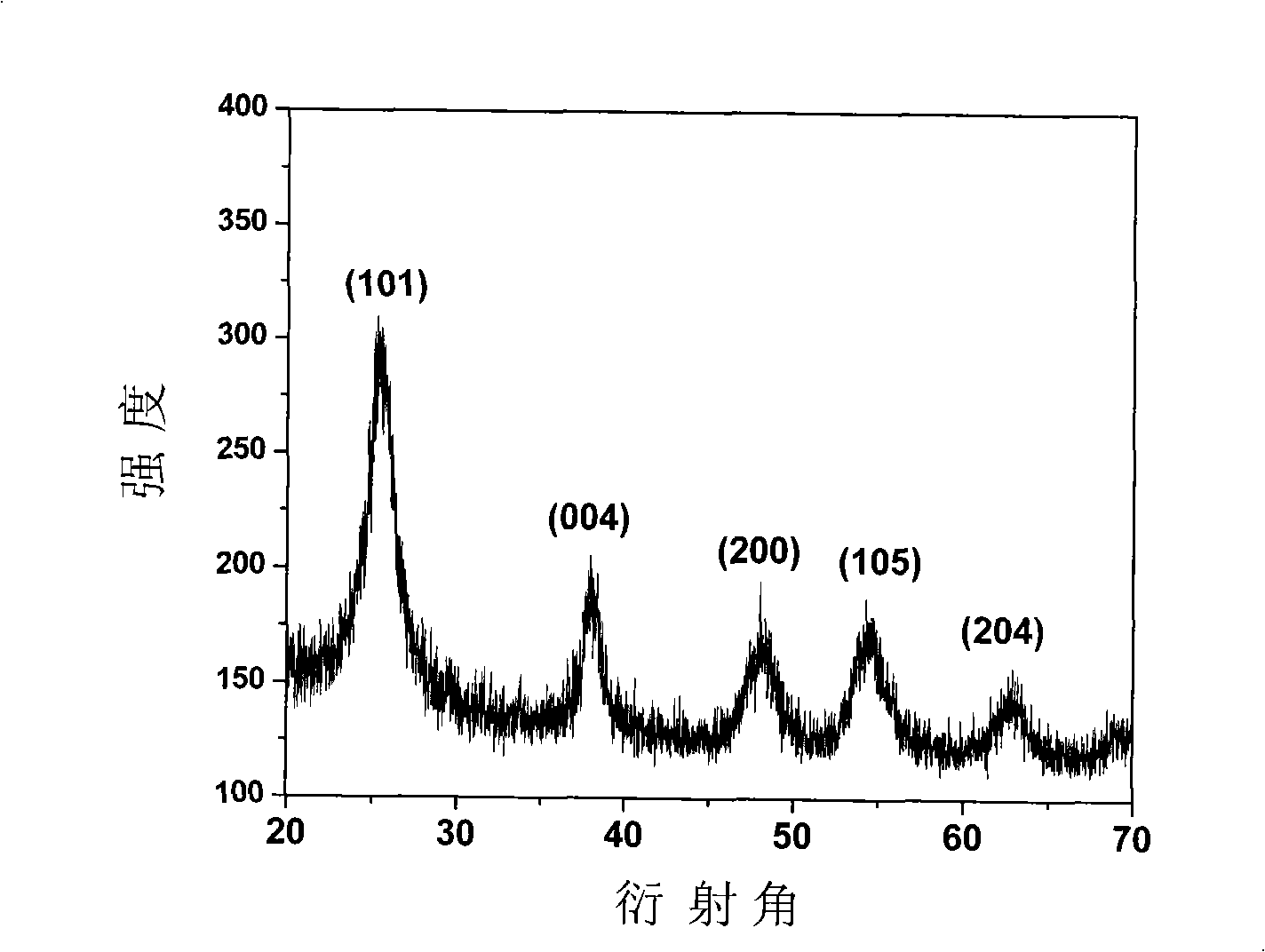

[0023] Get a certain amount of benzyl alcohol, add L-hydroxyproline and stir to make it dissolve completely, the concentration of L-hydroxyproline is 0.05 mol / liter. Then, under vigorous stirring, titanium tetrachloride was gradually added to the above benzyl alcohol mixture to form a white emulsion, wherein the titanium content was 0.7 mol / liter, and then the white emulsion was left to stand at 60°C for 80 hours , to completely hydrolyze the titanium dioxide, centrifuge to obtain a white precipitate at the end of the reaction, wash the white precipitate with chloroform, and then dry it at 50 degrees to obtain white anatase titanium dioxide nanorods modified with L-hydroxyproline.

Embodiment 3

[0025] Under vigorous stirring, titanium tetrachloride was gradually added to benzyl alcohol to form a white emulsion, in which the titanium content was 0.7 mol / liter, and then the white emulsion was left to stand at 100°C for 60 hours to completely hydrolyze the titanium dioxide At the end of the reaction, a white precipitate was obtained by centrifugation, washed with chloroform, and then dried at 50 degrees to obtain white anatase titanium dioxide nanorods.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap