Fuel gas moisture monitoring device and moisture monitoring method

A fuel gas and monitoring device technology, applied in the field of moisture devices, can solve the problems of not knowing the monitoring technology, having never done it before, and inappropriate long-term reliable monitoring, so as to reduce the maintenance frequency and calibration frequency, and simplify the process. Principle, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

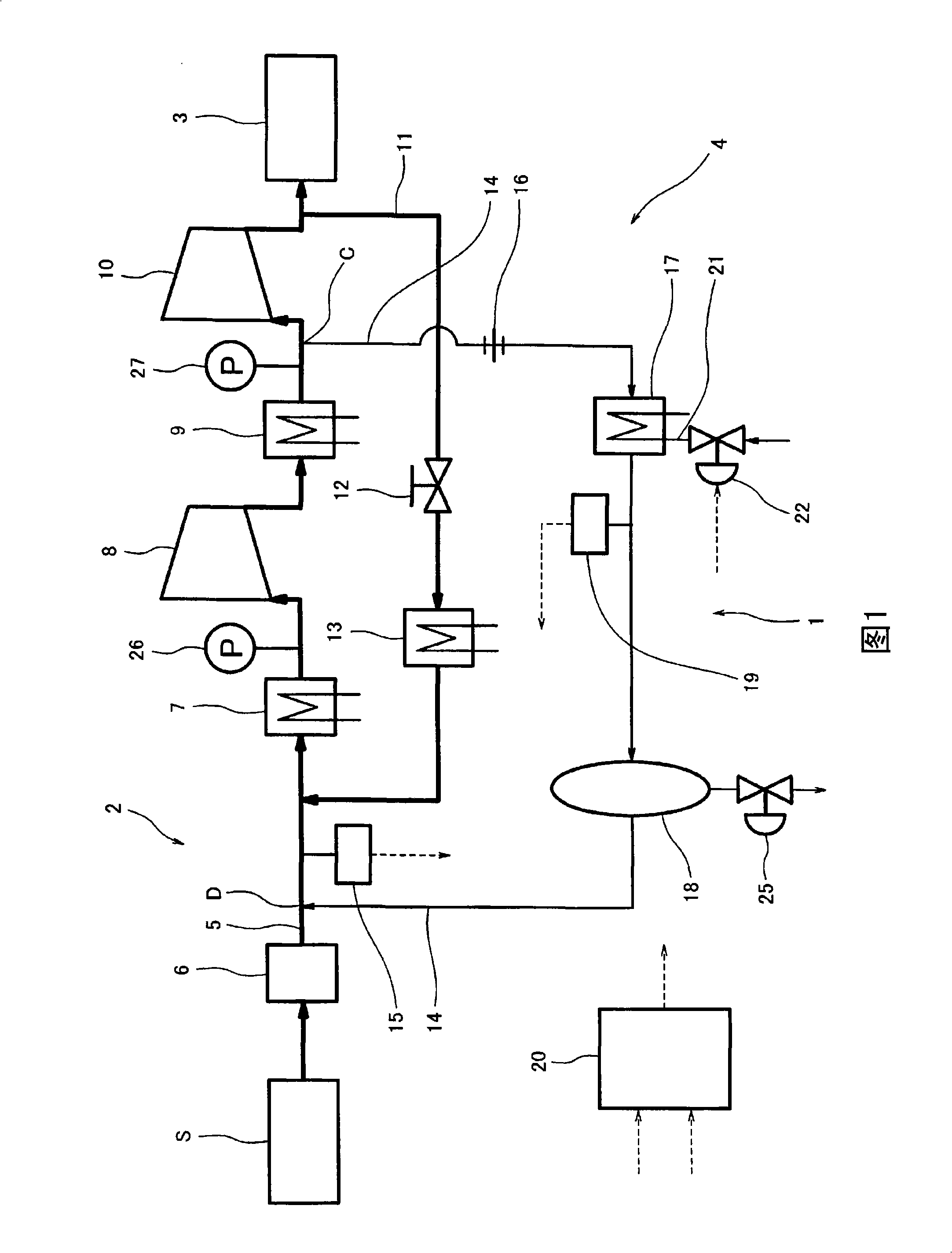

[0091] Next, an embodiment of a fuel gas moisture monitoring device and a moisture monitoring method according to the present invention will be described with reference to the drawings. 1 is a piping diagram illustrating a gas turbine power generation facility 4 including a fuel gas supply facility 2 provided with a fuel gas moisture content monitoring device 1 according to an embodiment of the present invention and a gas turbine 3 . The object of use of the moisture monitoring device of the present invention is not limited to such a gas turbine power generation facility 4 .

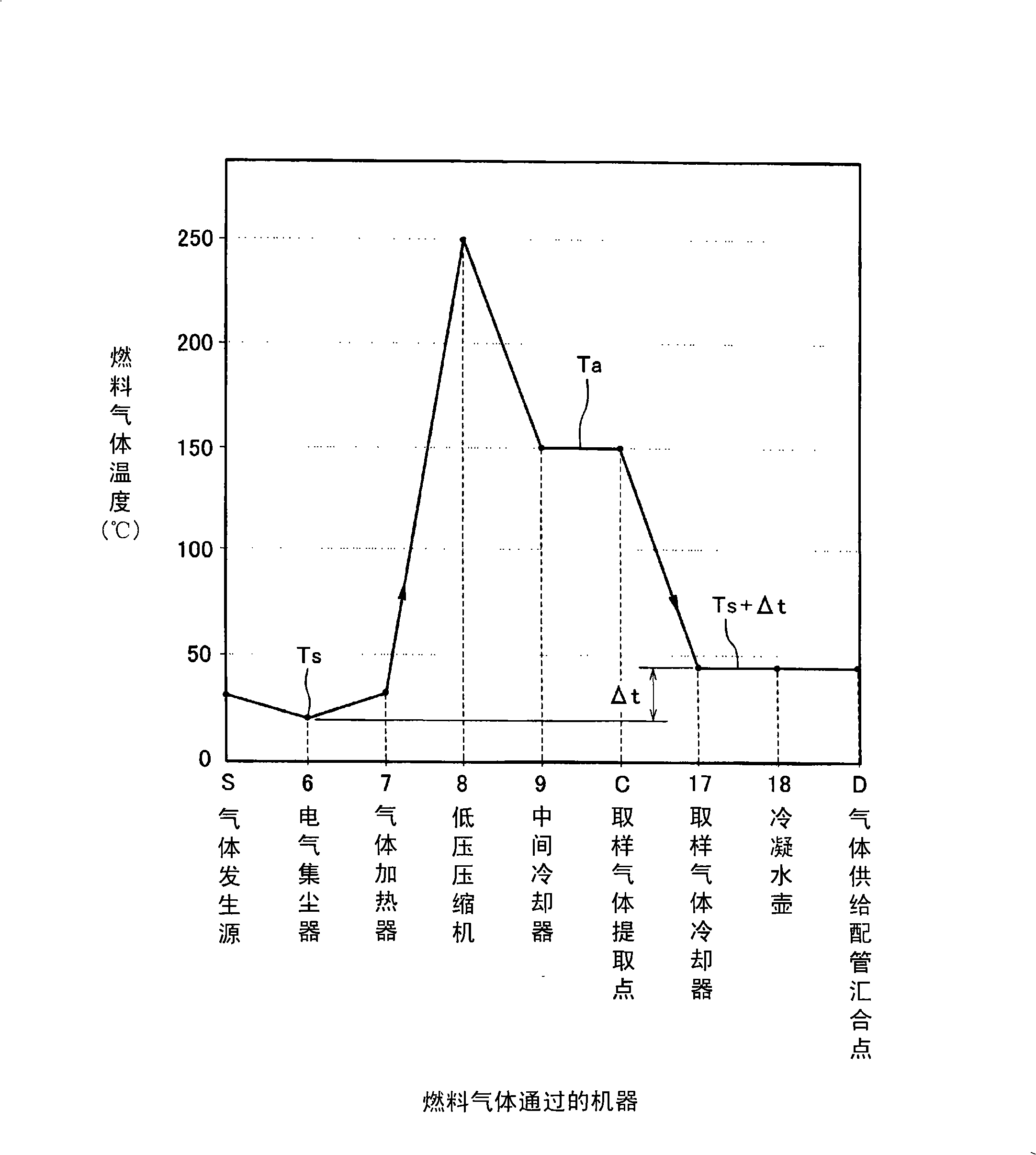

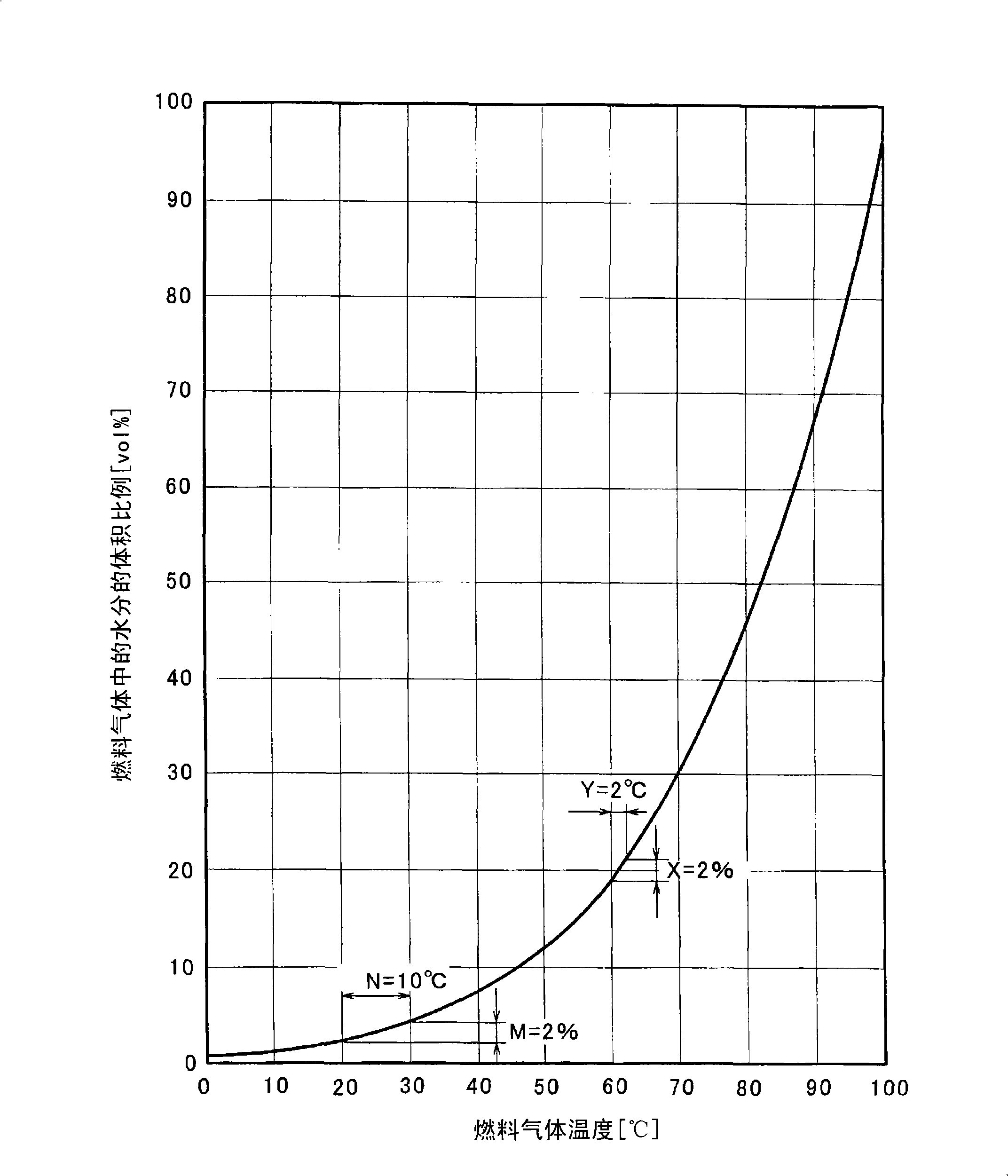

[0092] In FIG. 1 , by-product gas generated by a gas generating source S such as a blast furnace or a direct reduced iron facility is supplied to a gas supply pipe 5 of a fuel gas supply facility 2 as fuel for a gas turbine 3 . On the gas supply pipe 5 connected to the gas turbine 3, an electric dust collector 6, a gas heater 7, a low-pressure fuel gas compressor (hereinafter simply referred to as a low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com