Following hydrogen manufacturing fuel cell fuel system and device thereof

A fuel cell and hydrogen production device technology, applied in fuel cells, hydrogen, circuits, etc., can solve problems such as short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

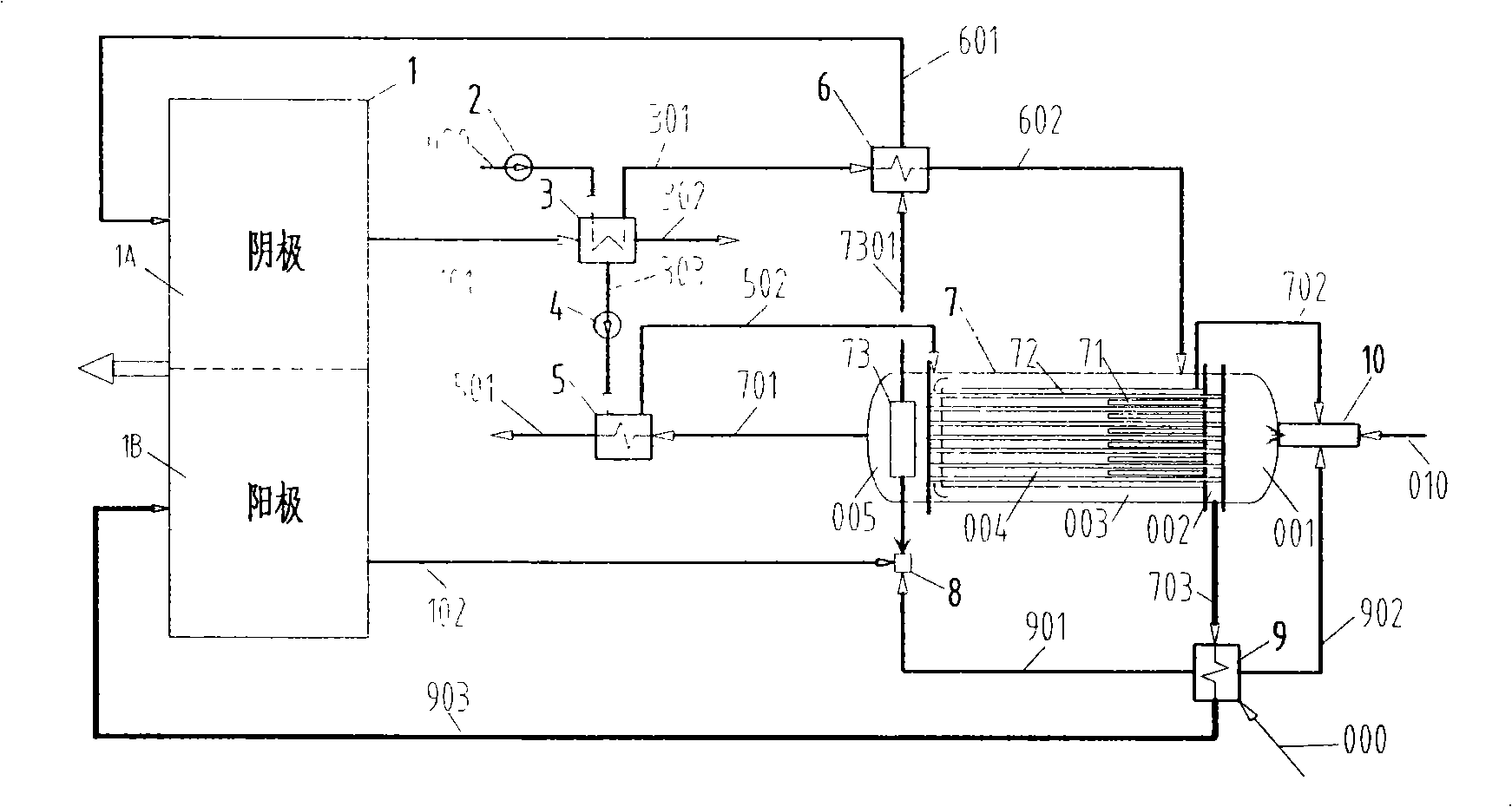

Embodiment 1

[0074] Such as figure 1 As shown, a portable hydrogen production fuel cell fuel cell consisting of a fuel cell 1, a fuel preheating heat exchanger 3, a regenerated water evaporation heat exchanger 5, a fuel evaporation heat exchanger 6, an air purification device 73, and a portable hydrogen production device 7, etc. The system and its devices are characterized by a compact accompanying hydrogen production device 7 integrating a tubular separation membrane 71 and a desulfurization chamber 003. The air purification 73 is built into the tail gas chamber 005 of the compact accompanying hydrogen production device 7. The direct combustion fuel for purifying air is Excess hydrogen from the anode exhaust of the fuel cell 1; the system connection and process are as follows: the combustion flame ejected from the burner 10 enters the combustion chamber 001 of the accompanying hydrogen production device 7 to fully burn to form heating gas, and the heating gas passes through the heat exchan...

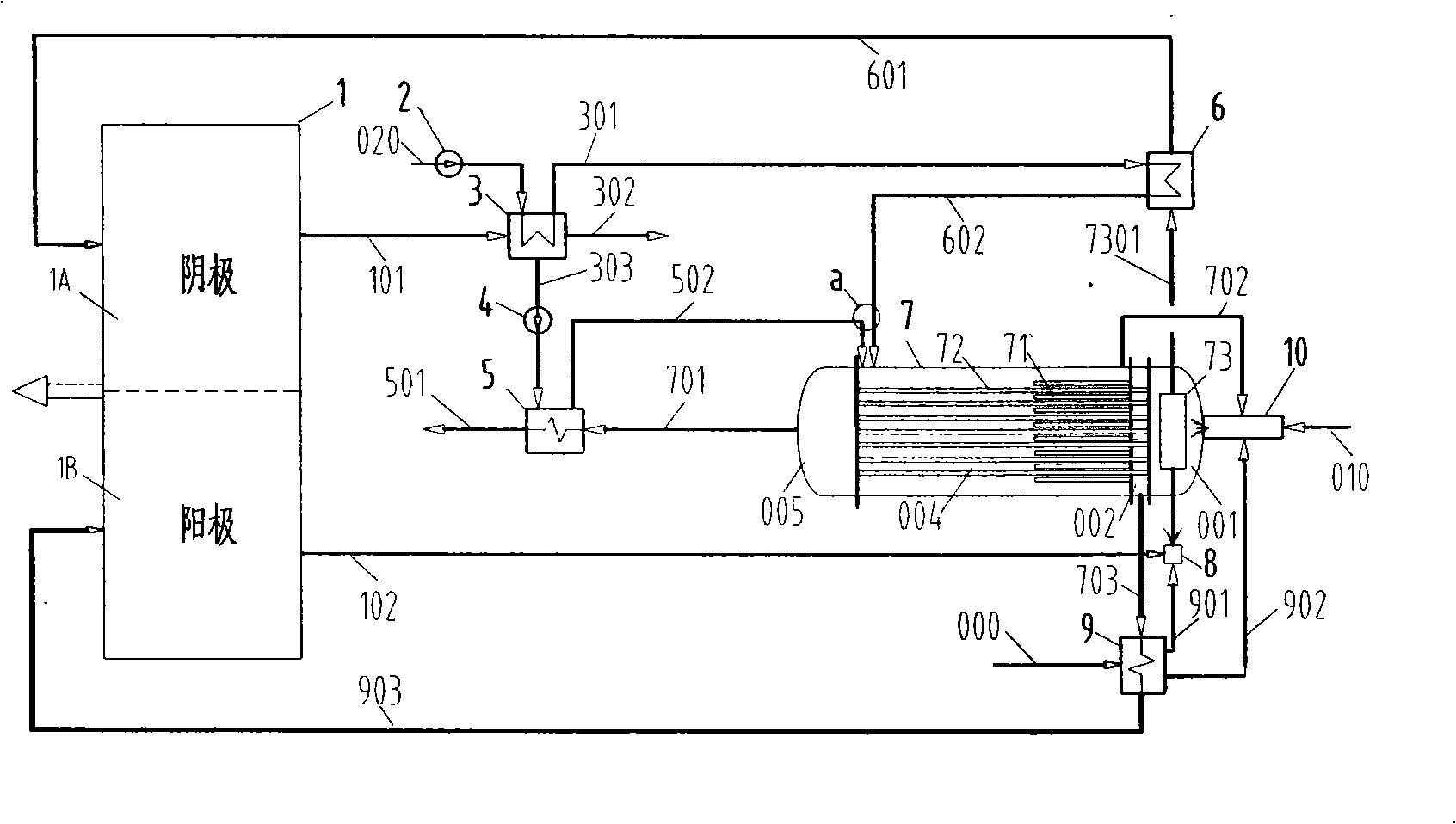

Embodiment 2

[0076] Such as figure 2As shown, a portable hydrogen production fuel cell is composed of a fuel cell 1, a fuel preheating heat exchanger 3, a regenerated water evaporation heat exchanger 5, a fuel evaporation heat exchanger 6, an air cleaner 73, and a portable hydrogen production device 7. The fuel system and its device are characterized in that the compact portable hydrogen production device 7 with integrated tubular separation membrane 71, the air cleaner 73 is built in the combustion chamber 001 of the compact portable hydrogen production device 7, and the direct combustion fuel for purifying air is a fuel cell The excess hydrogen gas exhausted by the anode of 1; the system connection and process are as follows: the combustion flame ejected from the burner 10 enters the combustion chamber 001 of the accompanying hydrogen production device 7 to fully burn to form heating gas, and the heating gas enters through the heat exchange tube 72 Exhaust gas cavity 005, then enters th...

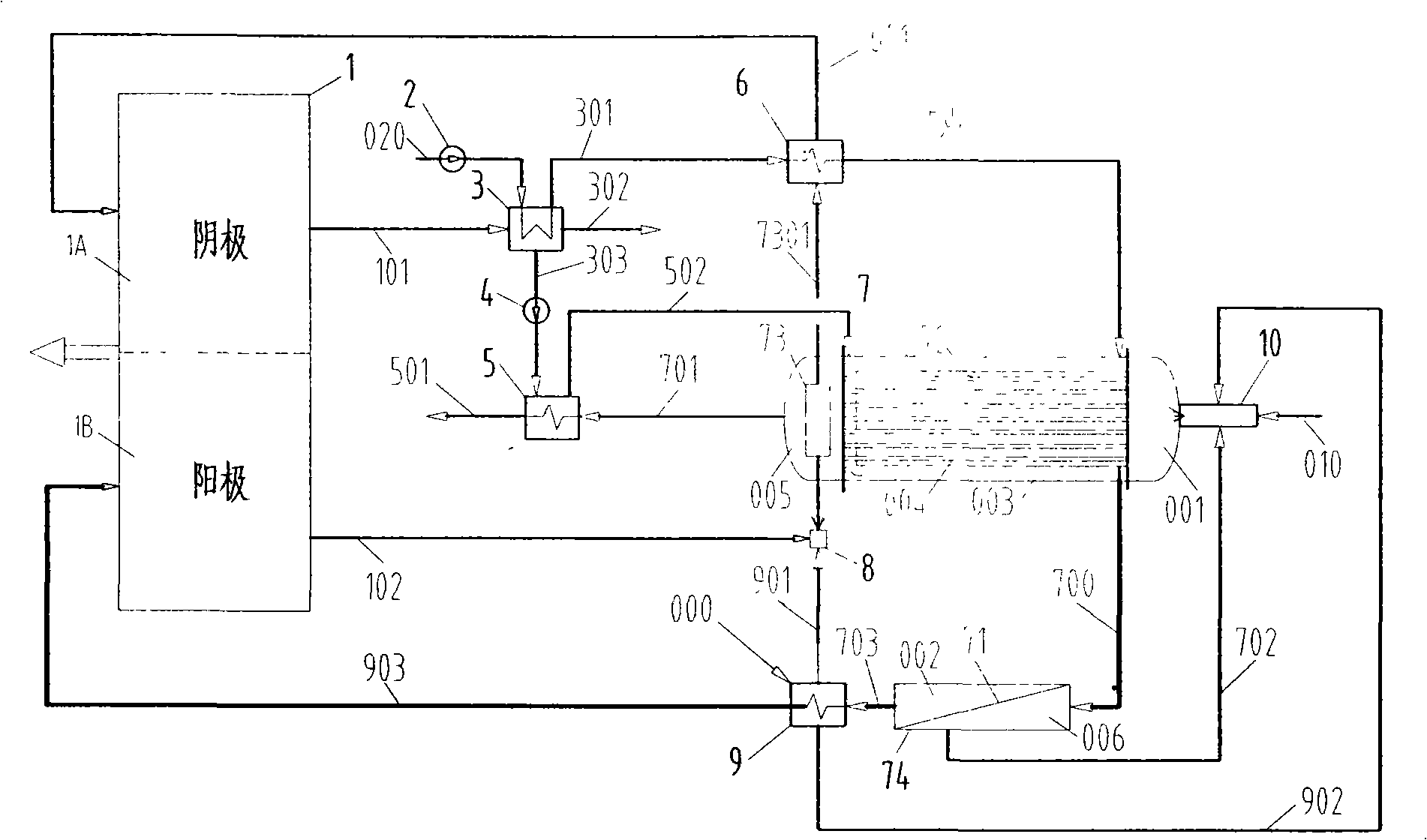

Embodiment 3

[0078] Such as image 3 As shown, one is composed of a fuel cell 1, a fuel preheating heat exchanger 3, a regenerated water evaporation heat exchanger 5, a fuel evaporation heat exchanger 6, an air cleaner 73, a hydrogen purification separator 77, and an accompanying hydrogen production device 7, etc. The on-board hydrogen production fuel cell fuel system and its device are characterized in that the compact on-board hydrogen production device 7 integrating the desulfurization chamber 003, the air cleaner 73 is built in the tail gas chamber 005 of the compact on-board hydrogen production device 7, and the hydrogen purification separator 74 Purify and separate hydrogen, and the direct combustion fuel for purifying air is excess hydrogen exhausted by the anode of fuel cell 1; the system connection and flow are as follows: the combustion flame ejected from the burner 10 enters the combustion chamber 001 of the accompanying hydrogen production device 7 for complete combustion Heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com