High-temperature high-voltage miniature laser deuterium-deuterium atomic fusion neutron pipe

A high-temperature, high-pressure, neutron tube technology, applied in neutron sources, DC voltage accelerators, etc., can solve the problems of low output, short service life, and low sub-yield, and achieve high output, small size, and long service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

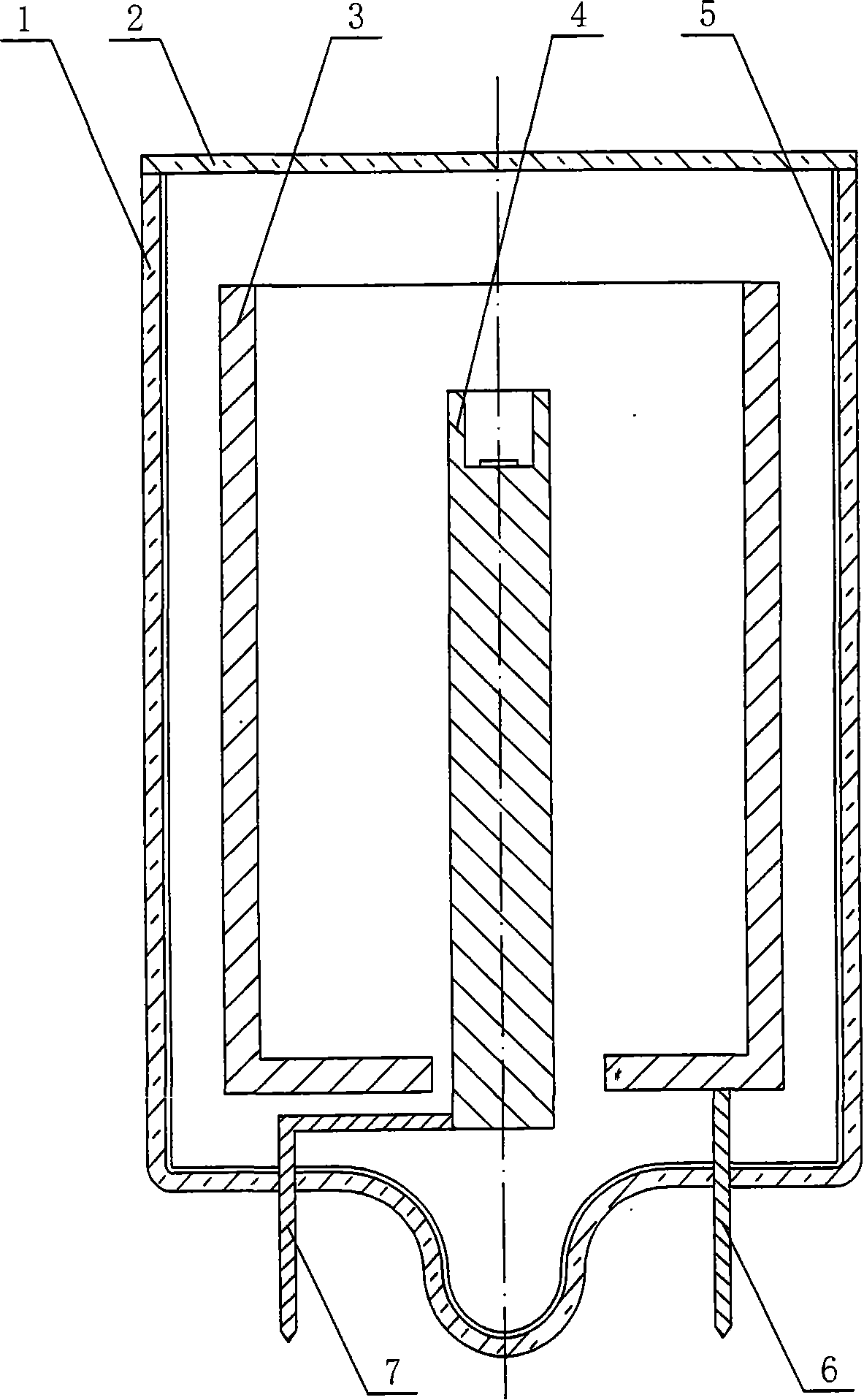

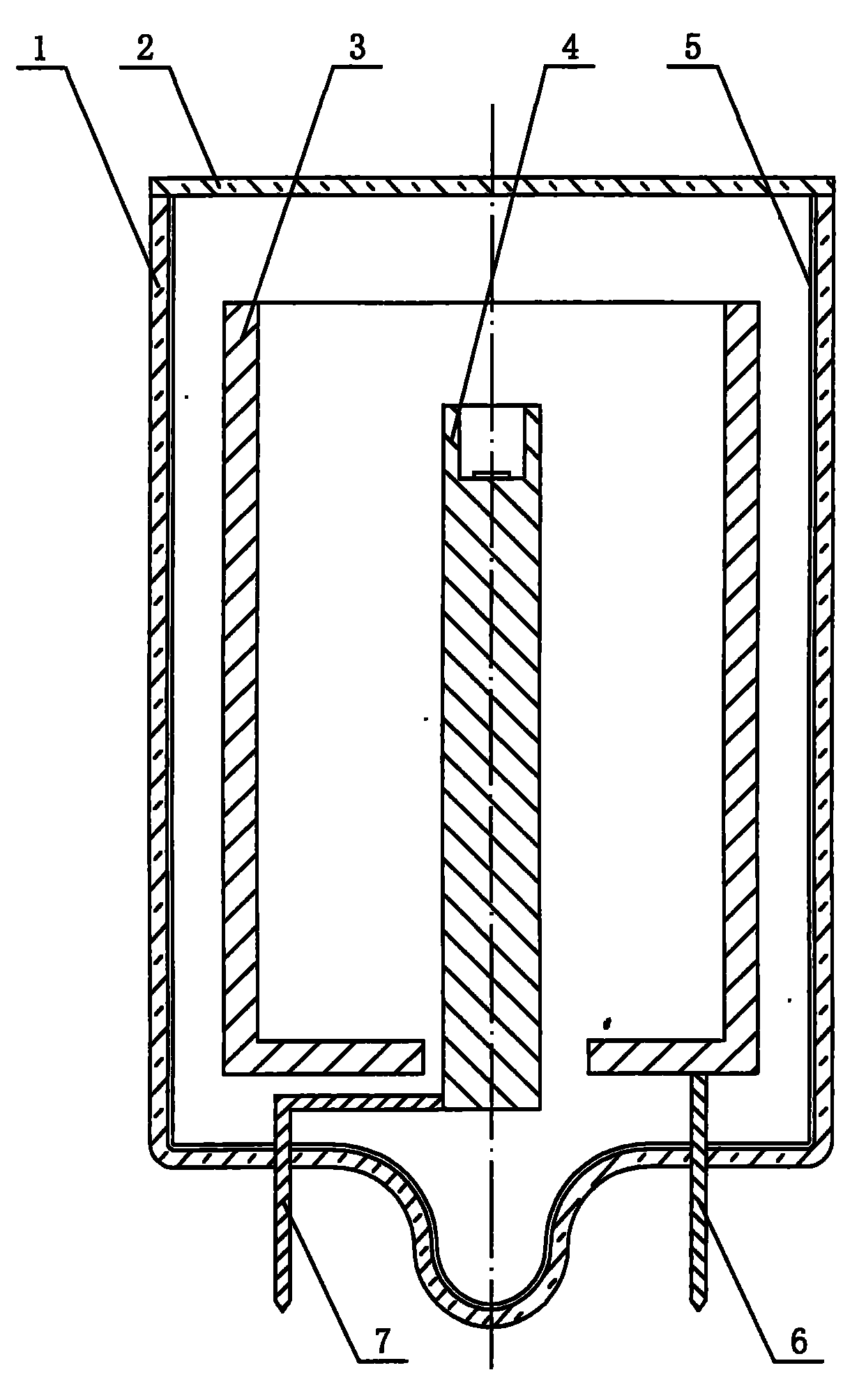

[0013] exist figure 1 Among them, the high-temperature and high-pressure small laser deuterium-deuterium fusion neutron tube of this embodiment is composed of a tube body 1, a glass window 2, a cathode 3, an anode 4, an insulating layer 5, a cathode pin 6, and an anode pin 7.

[0014] The pipe body 1 is a glass pipe body 1 or a ceramic pipe body 1. The outer diameter of the pipe body 1 is 50mm. When the inner wall of the pipe body 1 is sintered, a layer of insulating layer 5 is sintered, and the top of the pipe body 1 is sintered and fixed with a glass window 2. , the laser emitted by the laser source can be injected into the catheter body 1 from the glass window 2, and the cathode pin 6 and the anode pin 7 connected with the tube body 1 are sintered and fixed outside the lower end of the tube body 1. A cathode 3 is sintered and fixed in the tube body 1 at the same center line as the tube body 1. The cathode 3 is connected with the cathode pin 6 as a whole. The cathode 3 is a ...

Embodiment 2

[0019] In the present embodiment, the outer diameter of cathode 3 is 40 mm, the inner diameter is 32 mm, and the height is 110 mm. The bottom center of cathode 3 is processed with a central hole with a diameter of 22 mm. The anode 4 is a rod-shaped structure. The outer diameter of anode 4 is 8 mm, The height is 100mm. After the inside of the tube body 1 is evacuated to a vacuum, it is filled with pure deuterium gas, and the pressure of the deuterium gas is 535Pa. Other components and the coupling relationship of the components are the same as in Embodiment 1.

[0020] The principle of neutron generation in the high-temperature, high-pressure small laser deuterium-deuterium fusion neutron tube in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0022] In the present embodiment, the outer diameter of the negative electrode 3 is 40mm, the inner diameter is 34mm, and the height is 150mm. The bottom center of the negative electrode 3 is processed with a central hole with a diameter of 23mm. The anode 4 is a rod-shaped structure. The outer diameter of the anode 4 is 15mm. The height is 120mm. After the inside of the tube body 1 is evacuated to a vacuum, it is filled with pure deuterium gas, and the pressure of the deuterium gas is 550Pa. Other components and the coupling relationship of the components are the same as in Embodiment 1.

[0023] The principle of neutron generation in the high-temperature, high-pressure small laser deuterium-deuterium fusion neutron tube in this embodiment is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com