Method and device for charging processing plants

A processing equipment and charging technology, which is applied in combustion methods, combustion equipment, solid fuel pretreatment, etc., can solve problems such as blockage of conveying pipelines, inability to ensure, and long service time, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

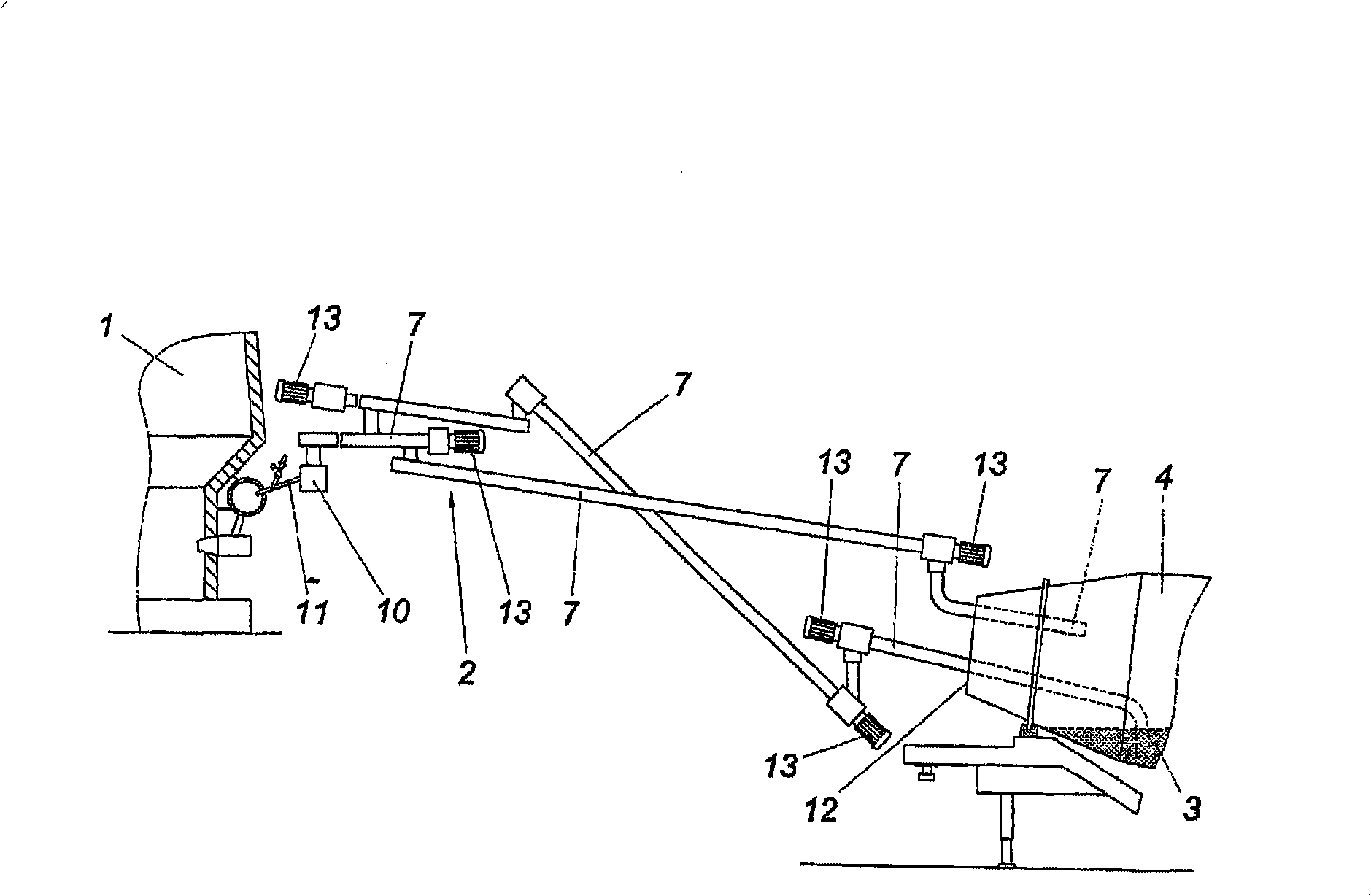

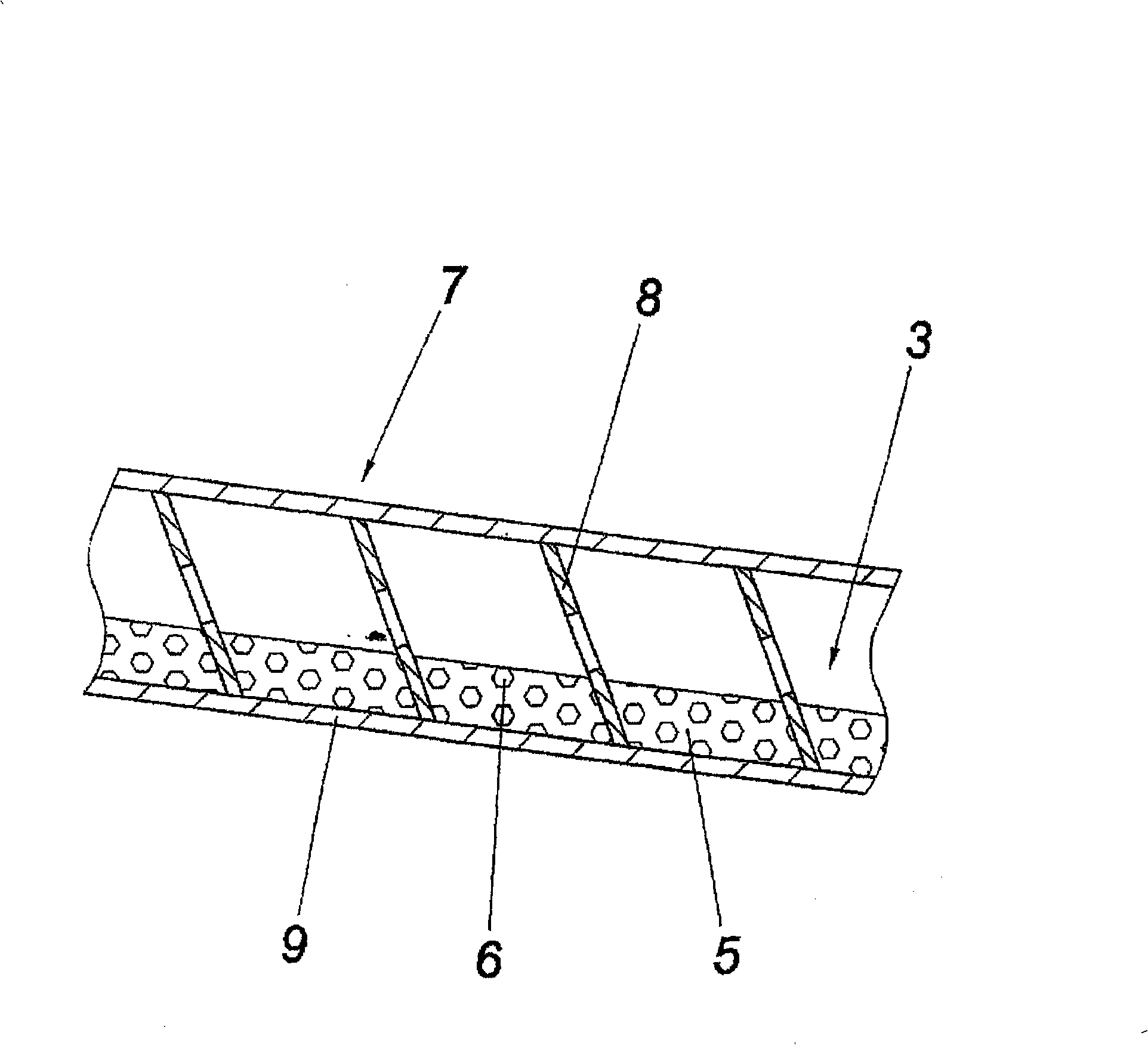

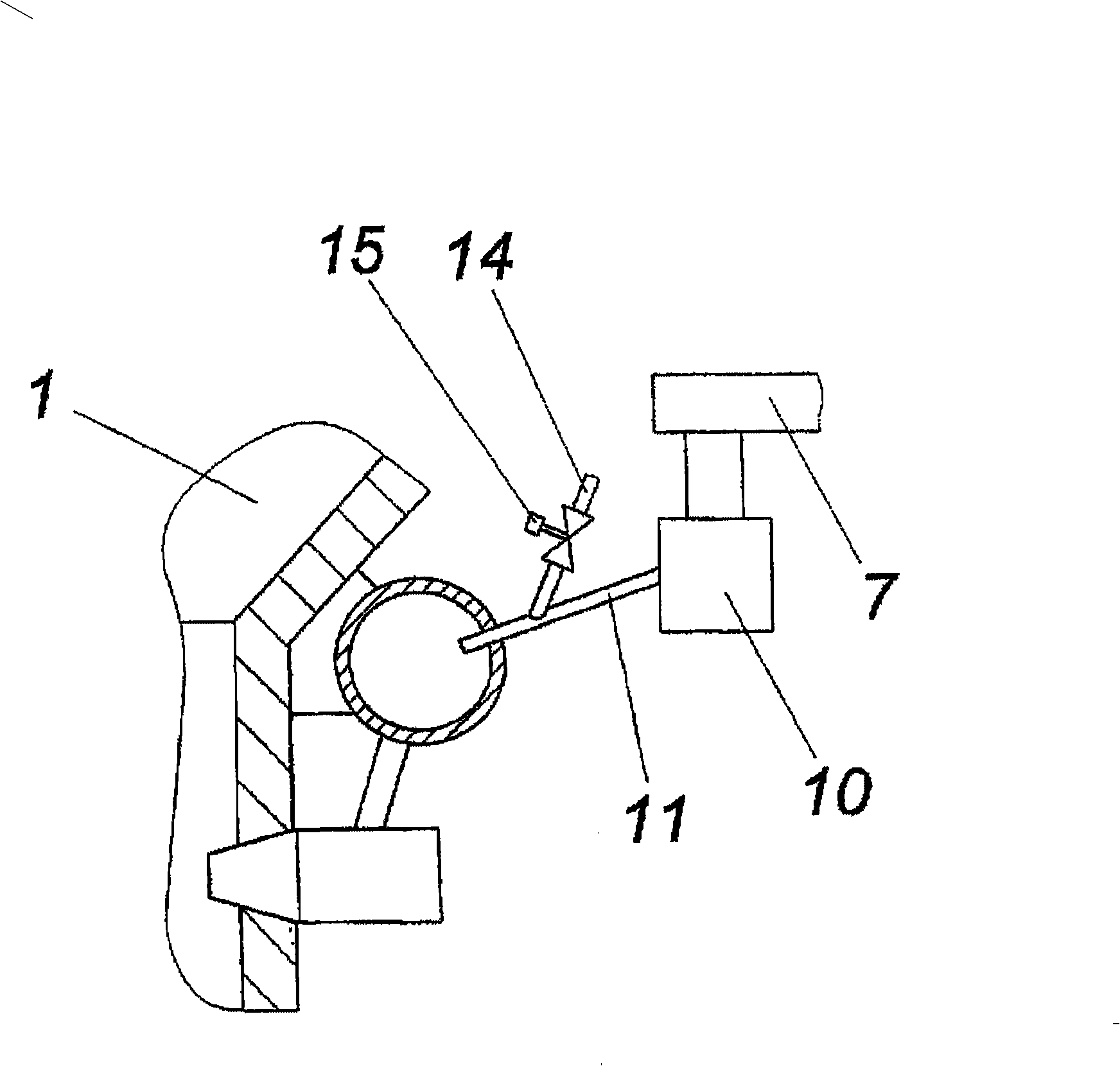

[0018] figure 1 The charging device shown by way of example for a treatment plant designed as a combustion furnace 1 has a delivery line 2 with which flowable treatment material 3 is received and charged into the combustion furnace 1 . The conveying line 2 draws the process material 3 from a mixer constituted as a drum mixer 4, which is responsible for continuously supplying the conveying line 2 with the process material 3, wherein a liquid part 5 is mixed with a solid part 6, in particular The solid part 6 is distributed almost evenly in the liquid part 5, which can be referred to in particular figure 2 . This flowable process material 3 can be, for example, a mixture of oil or sludge with plastics, metals and / or silicates.

[0019] From figure 2 It can be seen that in this section the conveying line 2 , which is formed as a screw conveyor 7 , is used for pressure-free conveying of the process material 3 . However, it is also conceivable to use a pump-pressurized convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com