Intravascular stent with PLGA blend medicament eluting surface coating

A PLGA and surface coating technology, which is applied in the field of medical materials and medical vascular stents, can solve the problems of restricting polymer applications, poor mechanical properties, and loss of function of drug-eluting stents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

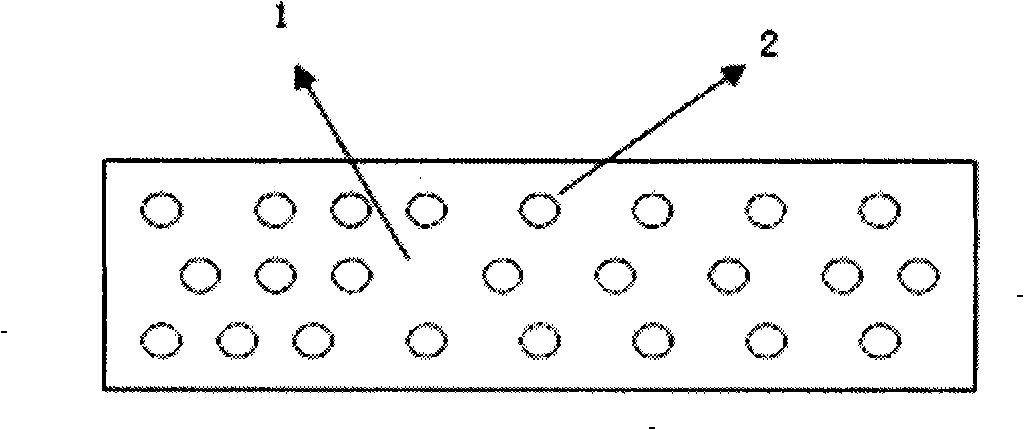

[0028] Embodiment 1: First, the two blending components are dissolved in an organic solvent according to the ratio of PEG or PEO:PLGA=1 to 40%, and a uniform polymer solution is prepared. Add the drug to the polymer solution according to the ratio of drug: polymer drug-loaded material = 5% to 40%, and add a certain volume of organic solvent to prepare a uniform coating solution with a certain concentration. Finally, a single-layer drug coating is prepared by ultrasonic atomization and spraying. The specific coating structure is as follows: Figure 1-a , where 1 is the PLGA blend and 2 is the drug.

specific Embodiment approach 2

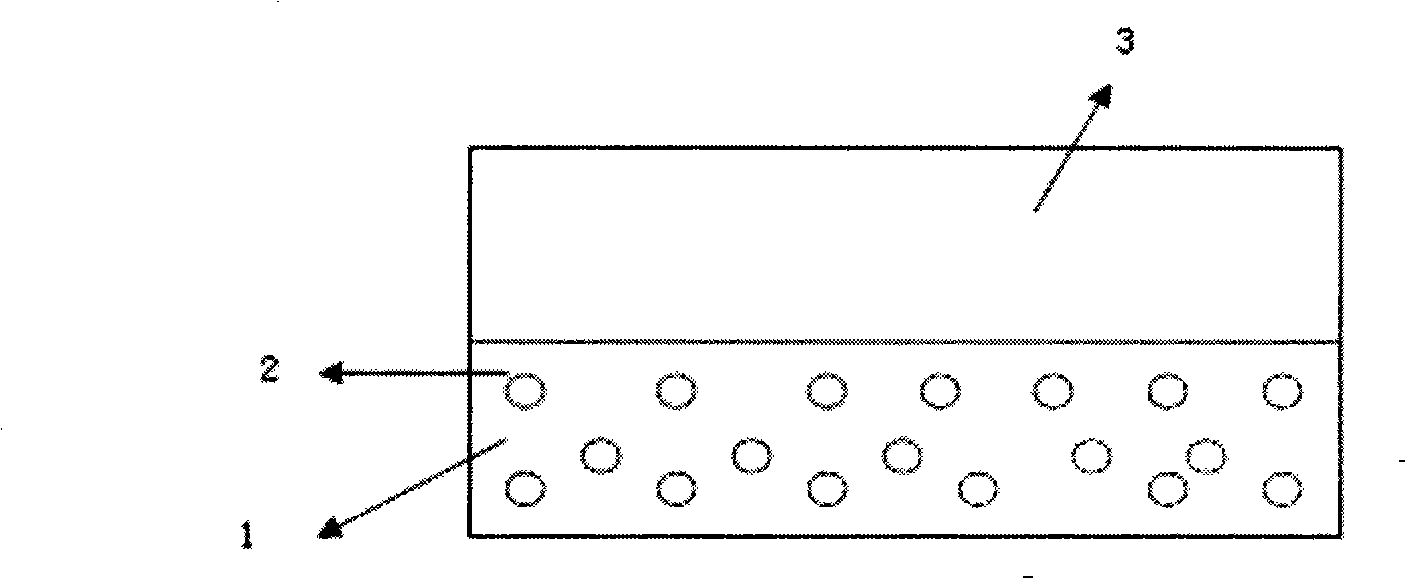

[0029] Embodiment 2: Prepare the blend drug solution and polymer solution according to the ratio described in the method 1. Spray the blended drug solution and the polymer solution on the surface of the stent by ultrasonic atomization spraying in turn to form a double-layer drug coating. The specific coating structure is as follows: Figure 1-b As shown, 1 is the polymer drug-loaded material, 2 is the drug, and 3 is the non-drug polymer coating.

specific Embodiment approach 3

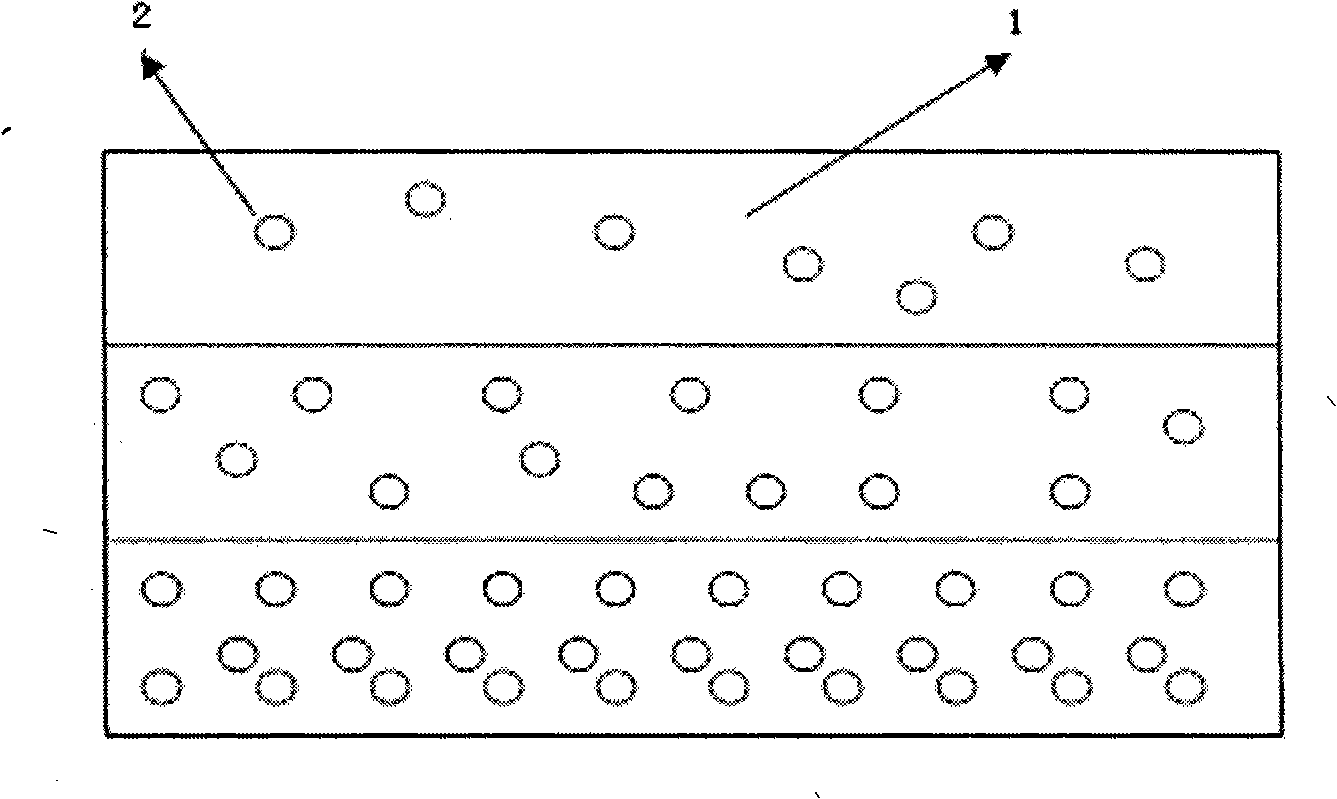

[0030] Embodiment 3: Prepare several blend drug solutions loaded with the same (or different) drugs and different drug concentrations according to the ratio described in method 1. According to the order of drug concentration from high to low, the blend drug solution is sprayed on the surface of the vascular stent by ultrasonic atomization spraying method to form a multi-layer drug coating. The specific coating structure is as follows: Figure 1-c shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com