Large-sized turbine generator stator core vibrating numerical computation method

A technology of steam turbine generator and stator core, applied in vibration testing, testing of machine/structural components, measuring devices, etc. Issues such as setting a range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

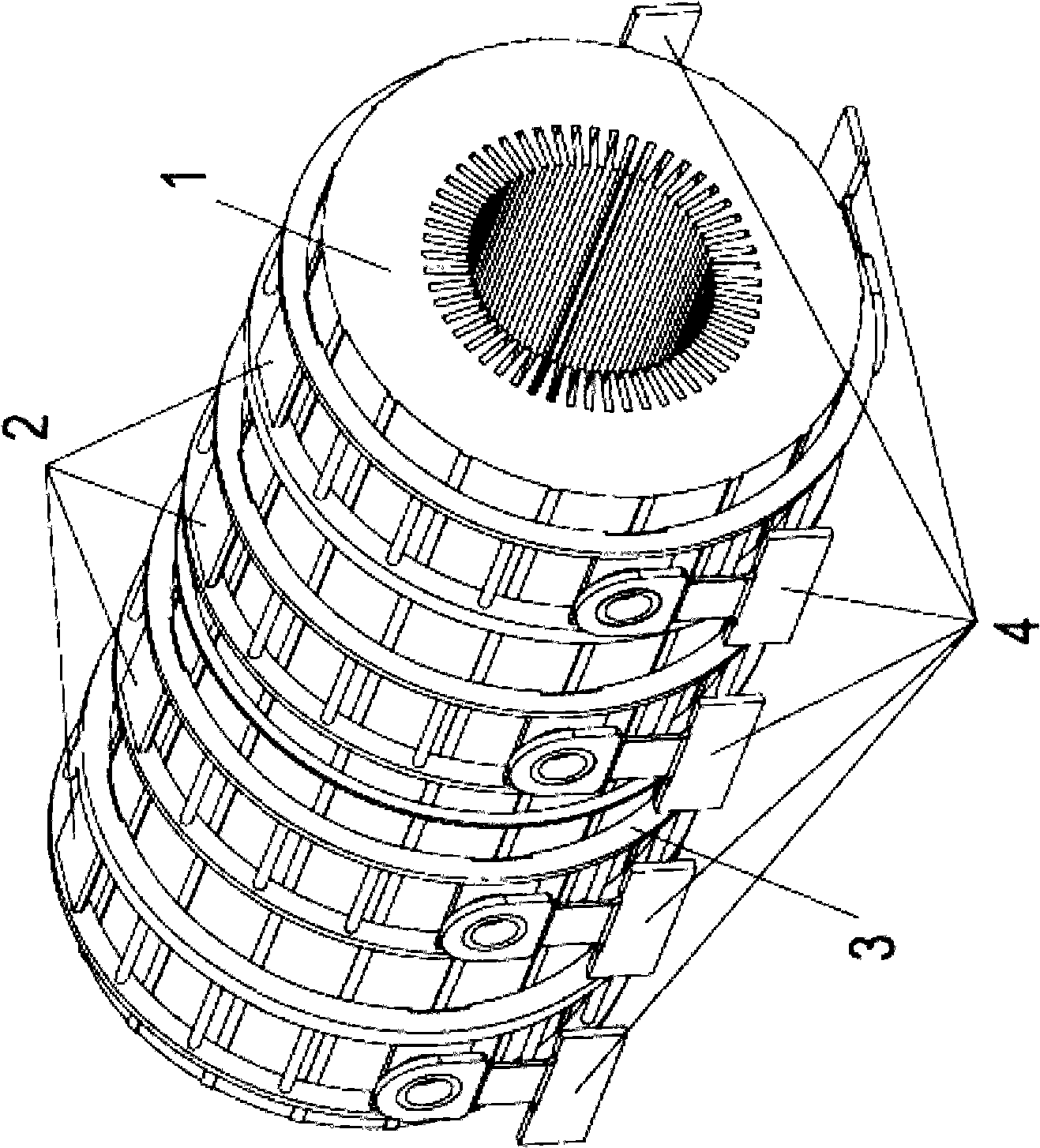

[0050] Such as figure 1 As shown, it is a simplified CAD model diagram of a large turbogenerator stator core, using the stator core of a certain large turbogenerator as the analysis object of the embodiment of the present invention, and its specific calculation steps are:

[0051] The first step, model simplification

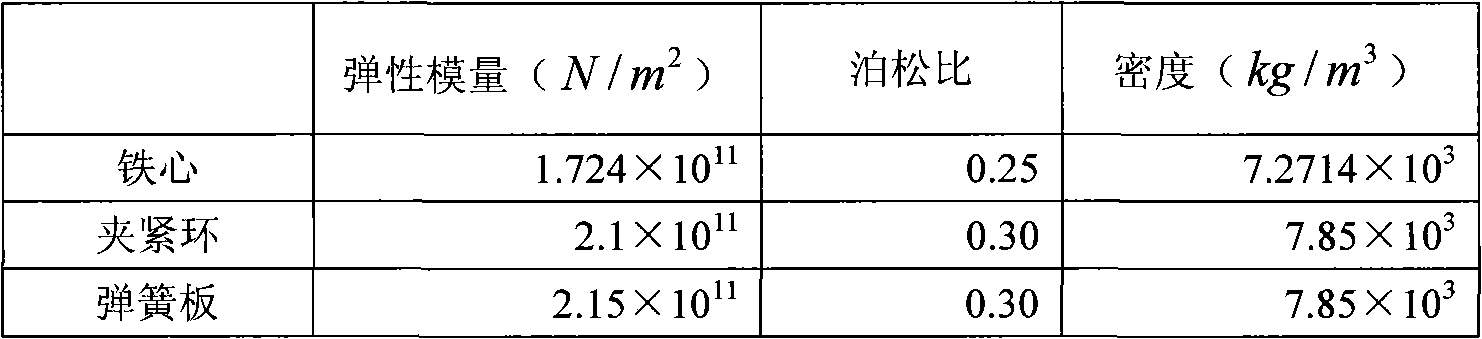

[0052] According to the stator core drawing of a large steam turbine generator, the simplified stator core model is established by using Pro / E software. Neglecting the stiffness of the stator coil, the air duct and other gaps of the stator core are only considered for simple mass reduction, and the rest of the parts (including the stator core 150480kg, the stator coil 12260kg, the excitation end pressure ring 2508kg, the steam end All the weights of pressure ring 2508kg, iron core pressing 2470kg and magnetic shielding 2×680kg) are equivalent to iron core 1 with teeth, and four clamping rings 2 and one support ring 3 are welded to the iron core, ten springs Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com