Exhauster

A wind device and air valve technology, which is applied in the field of wind unloading devices for solar reflectors, can solve the problems of lack of positioning, damage, and magnetic force not positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present application will be further described below in conjunction with the examples.

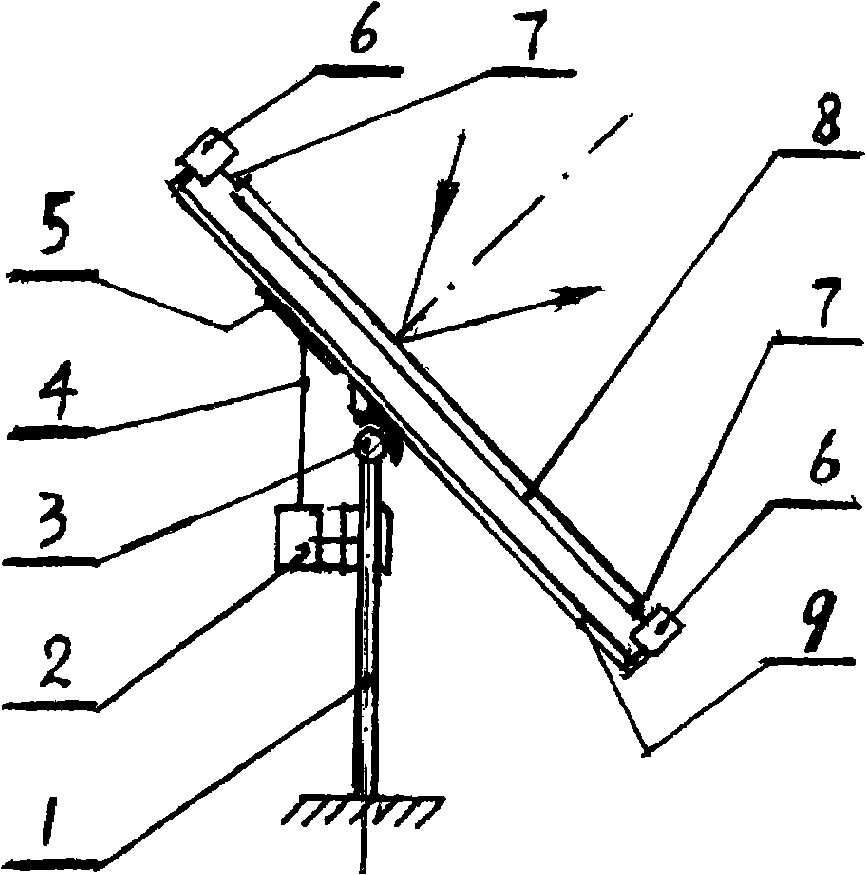

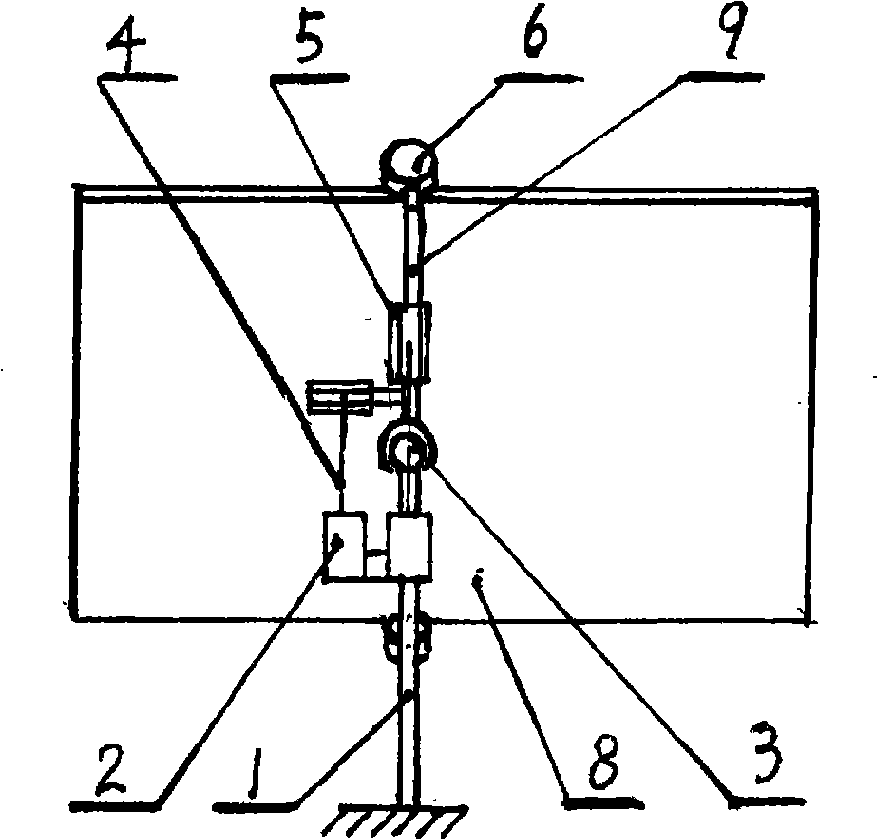

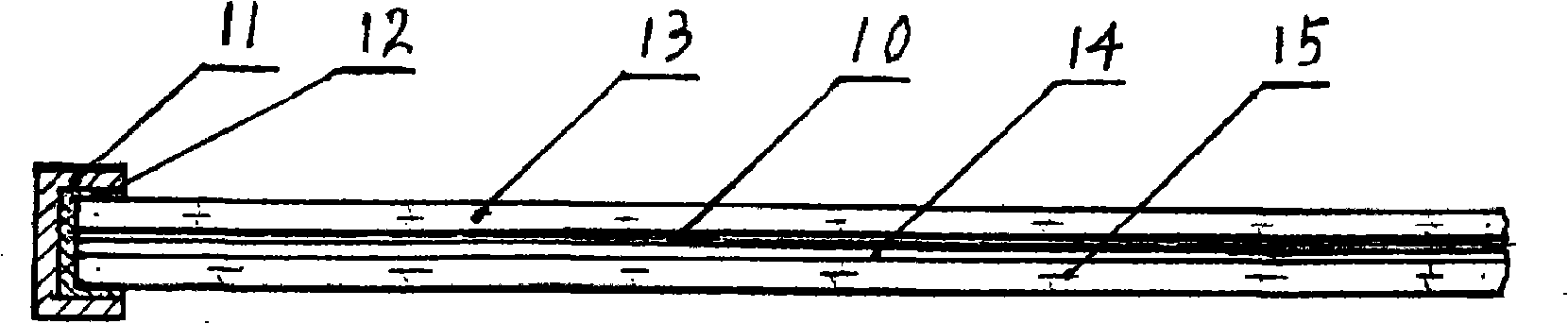

[0047] The first embodiment is an embodiment in which the frame is composed of a wind unloader connected with a safety glass lens and has a two-way air unloading function reflector. figure 1 It is a schematic diagram of the tower solar boiler heliostat installation. figure 2 is the side view of the heliostat installation. The heliostat is a flat reflector. The tower solar boiler is composed of a flat reflector 8, a boiler and equipment for transmission, storage, and heat utilization. The following flat reflector 8 is referred to as the reflector 8. The mirror 8 reflects solar radiation onto the boiler, where it is absorbed and converted into heat energy. Both symmetrical ends of the reflector 8 are respectively fixedly connected to the rotating shaft 7 of a multi-cavity two-way vane unloader 6. At both ends of the frame 9, the rotating shafts 7 of the two air unloaders 6 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com