Hydrogen preparing process by reacting pure alminuim powder with water

A process method, water reaction technology, applied in the direction of hydrogen production, etc., can solve the problems of slow reaction of metal Fe, strong alkali pollution, etc., and achieve the effect of cheap price and simple process equipment

Inactive Publication Date: 2008-10-15

SHANGHAI UNIV

View PDF0 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The problem with using NaBH4 as a hydrogen-producing material is that NaOH must be used as a solution stabilizer, so there is a problem of strong alkali pollution

However, at normal temperature and pressure, the reactions of metal Fe and Al with water are very slow and limited.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

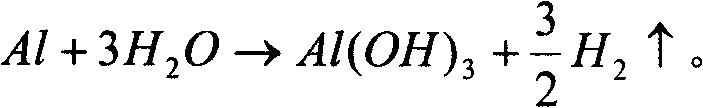

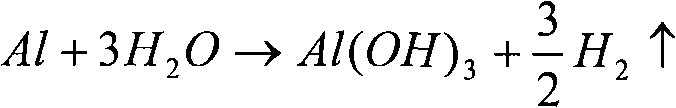

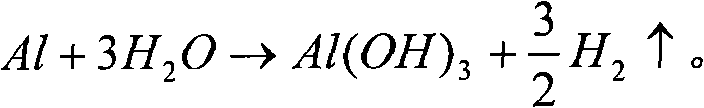

The invention provides a method for producing hydrogen through continuous reaction between pure aluminum powder body and water under the conditions of low vacuum and warm water. The main content of the method is as follows: putting a certain amount of fine A1 powder body into a closed vessel with a certain amount of water (the weight ratio of aluminum to water is 1:2-2.5), heating the water mixed with the Al powder body in the vessel to a certain temperature (such as 40 DEG C), and then vacuumizing to a certain low vacuum state (such as 3kPa, namely, the gas pressure of 0.03atm). The Al powder body can react with the water continuously and generate the hydrogen under the conditions of the temperature and the low vacuum. The speed for producing hydrogen by the reaction of the Al powder body and the water can be further increased if the reaction temperature is increased successively (shown in the attached figure 1). The hydrogen-producing method is mainly used for supplying hydrogen to fuel cells carried by fuel cell cars and other medium-sized and small-sized vehicles or appliances.

Description

Process method for generating hydrogen by reacting pure aluminum powder with water technical field The invention relates to a process method for producing hydrogen by reacting pure aluminum powder with water, which is a new simple and portable method for producing hydrogen, which can be directly used as fuel carried by fuel cell vehicles and other small and medium-sized transportation vehicles or devices. The battery provides the hydrogen source. The invention belongs to the technical field of chemistry and chemical engineering. Background technique With the global warming and the deterioration of the environment, people pay more and more attention to the research and development of clean energy technology. Fuel cells are the core of clean energy technology, because fuel cells directly convert chemical energy into electrical energy and thus have high efficiency and low pollution. Hydrogen is an ideal fuel for fuel cells because the oxidation product of hydrogen is water,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B3/08

CPCY02E60/36

Inventor 邓振炎

Owner SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com