Method for corroding of citrus segment membrane orange carpel by two-stage enzyme method

A technology of capsule coating and orange petals, applied in the field of fruit processing and utilization, can solve the problems of affecting product quality, large water consumption per ton, serious pollution, etc., and achieve the effects of easy popularization and application, reduction of crushing rate, and simple treatment.

Inactive Publication Date: 2008-10-22

ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

View PDF0 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The citrus decapsulation process is a key process in the production of canned citrus and citrus cysts. At present, the decapsulation process is treated with launder-type acid and alkali, which causes serious pollution and consumes a lot of water per ton

These problems can be alleviated by using biological enzyme method to remove the coat. Enzyme is a kind of macromolecular protein, and its diffusion coefficient in the coat is much smaller than that of small molecule acid-base, so the degradation rate is lower than that of ordinary acid-base method; The capsule coating is not a uniform film. It is thinner on the back of the orange slices, but thicker at the center and corners. The capsule coating is directly removed by enzymatic hydrolysis. The vascular bundles and capsule coatings of the fruit core and the corners cannot be completely removed, which affects Product quality, the technology in this area needs to be further improved and improved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

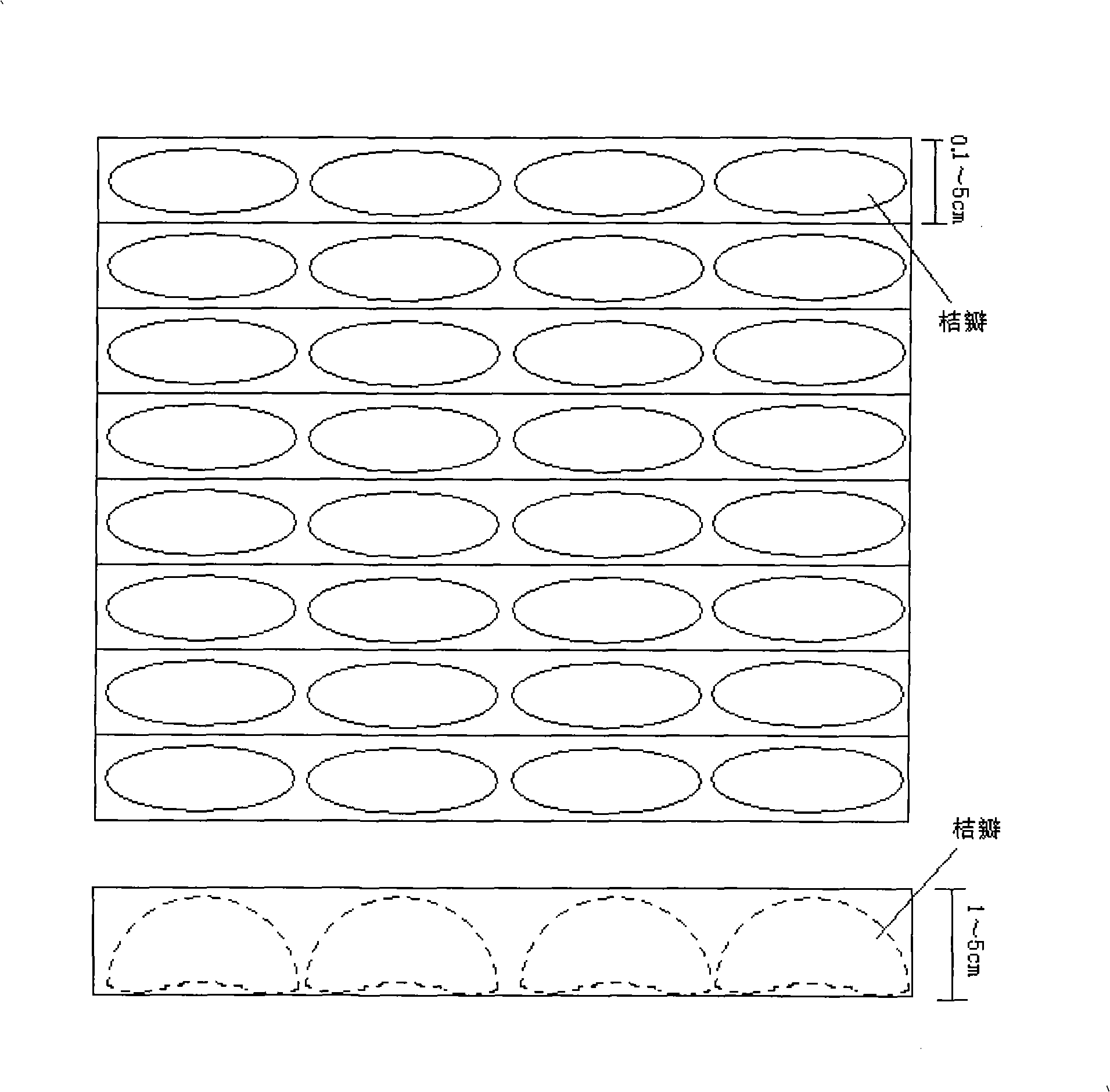

The invention discloses a method for completely peeling off the orange segments by using pectase. The method can entirely peel off the fruit cores and wrap angles that usually can not be entirely peeled off by enzyme method and reduces subsequent manual cleaning-up procedures. Peeled orange segments are arrayed on the shelves according to the direction that the fruit cores are downward, and then the fruit cores are carried out enzymolysis for 2-6 hours by using the 0.5%-2% of pectase with pH 3.0-5.0 at the temperature of 20-50 DEG C; or the fruit cores are injected with 0.5-2mL and 0.5%-2% of pectase with pH 3.0-5.0 from the center at the top of the orange fruits and then peeling is performed after the enzymolysis for 2-12 hours at the temperature of 10-50 DEG C. After the pretreatment, the orange segments are put into the enzyme solution entirely for degradation so as to get the orange segments with complete peeling. The method is simple and practical and solves the disadvantage of being difficult to peel off orange segments completely by the enzyme method.

Description

Two-stage enzymatic method for the whole peeling of citrus fruit petals Technical field: The invention relates to a method for enzymatically removing citrus fruit petal capsules, belonging to the field of fruit processing and utilization. Background technique: Citrus is the fruit with the largest planting output in the world. my country's citrus planting area and canned citrus production rank first in the world. The citrus decapsulation process is a key process in the production of canned citrus and citrus cysts. At present, the decapsulation process is carried out by launder-type acid-alkali treatment, which causes serious pollution and consumes a lot of water per ton. These problems can be alleviated by using biological enzyme method to remove the coat. Enzyme is a kind of macromolecular protein, and its diffusion coefficient in the coat is much smaller than that of small molecule acid-base, so the degradation rate is lower than that of ordinary acid-base method; The ca...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A23N7/01

Inventor 张俊夏其乐程绍南陆胜民邢建荣杨颖邵敏陈剑兵郑美瑜

Owner ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com