Melamine ware containing wood substance component and its manufacturing method

A technology of melamine and melamine powder, which is applied to drinking water vessels, cooking vessels, special materials for cooking vessels, etc., can solve problems such as non-compliance with environmental protection requirements, reducing the applicability and safety of melamine utensils, and limiting the applicability of melamine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

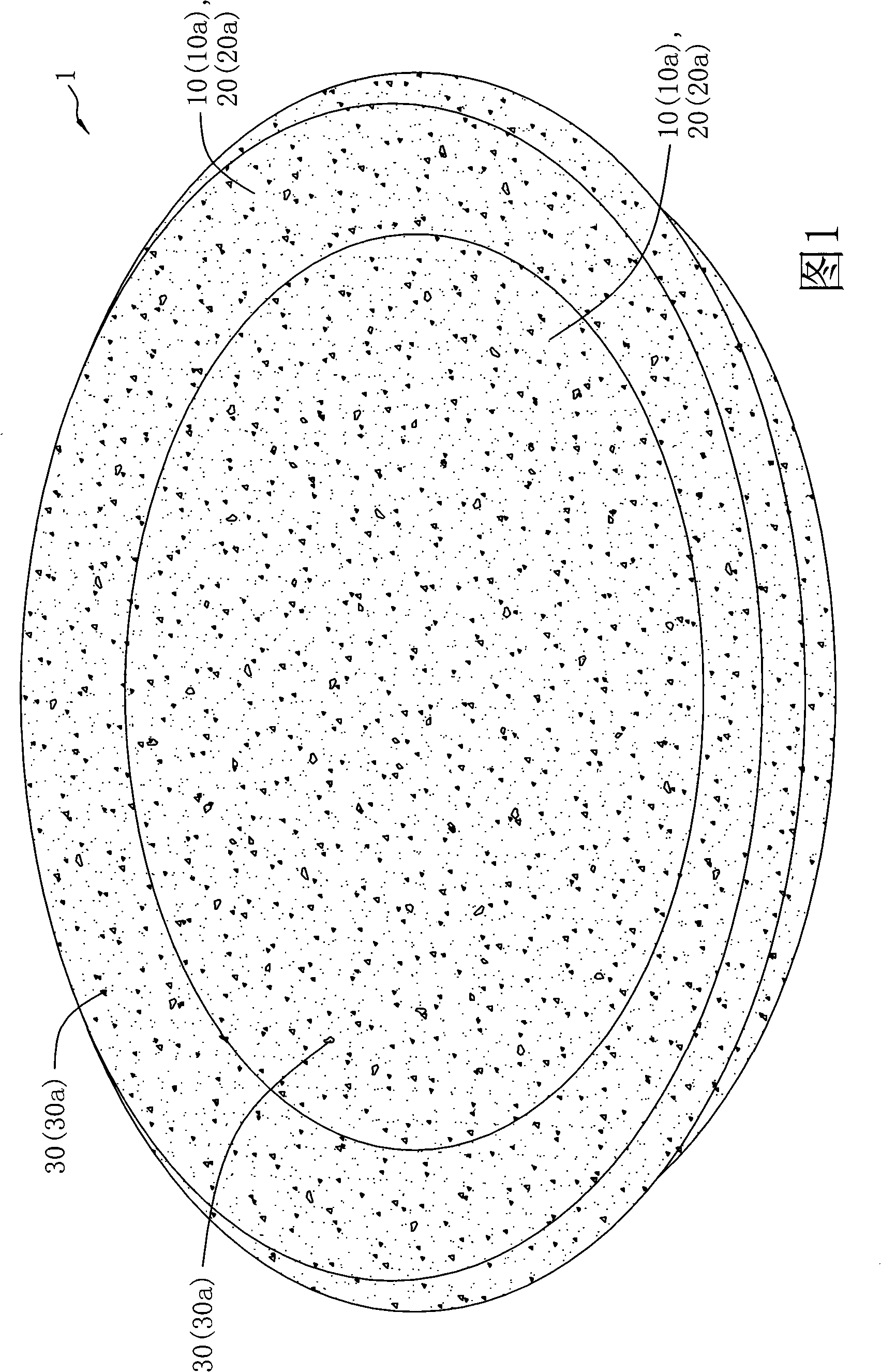

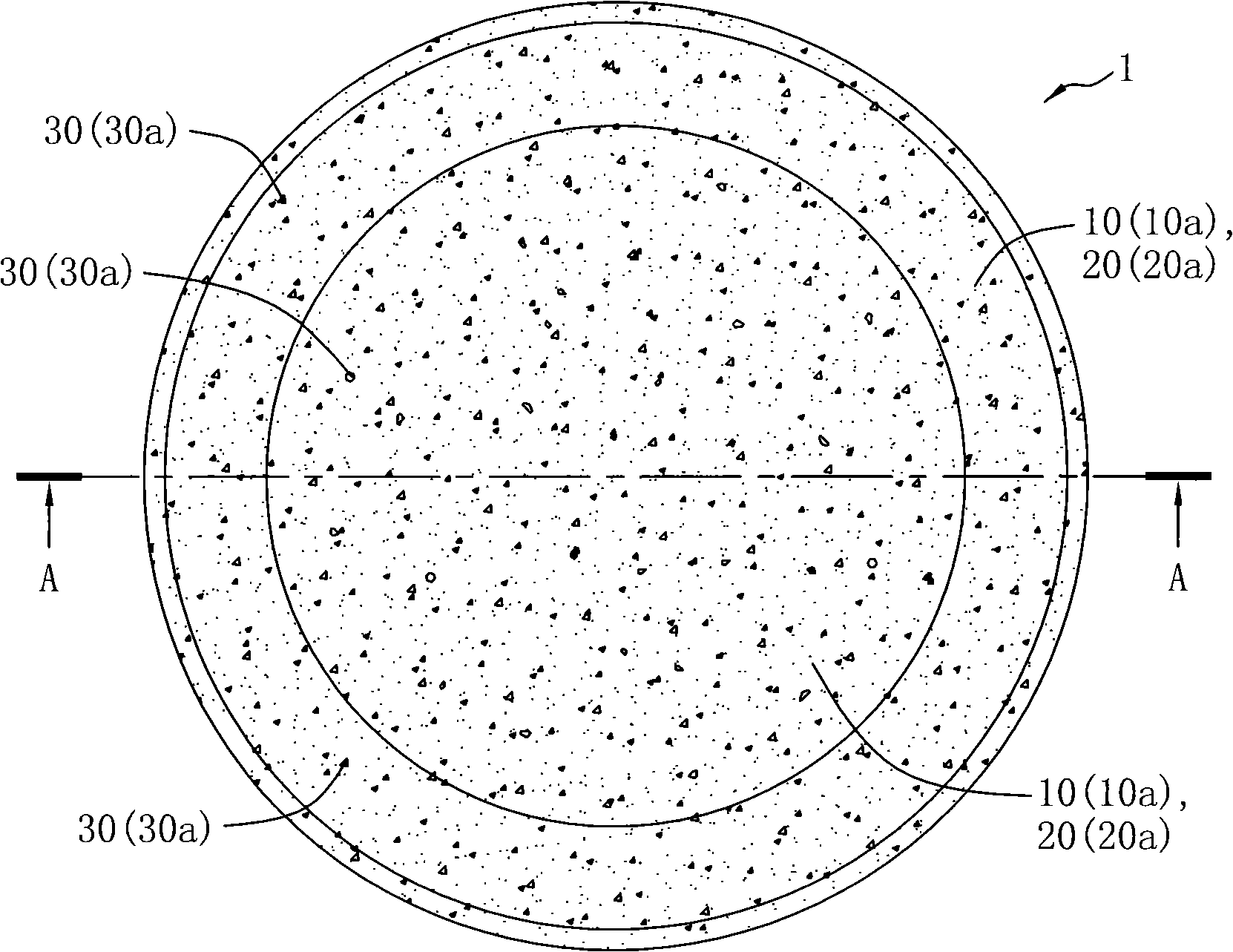

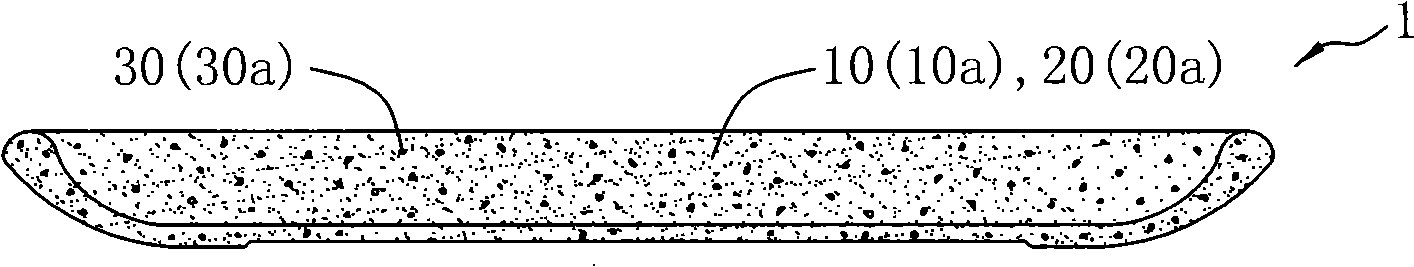

[0033] In order to make the present invention more definite and detailed, the preferred embodiments are listed hereby in conjunction with the following diagrams, and the structure and technical characteristics of the present invention are described in detail as follows:

[0034] Please refer to Figure 1~ Figure 5 As shown, they are respectively a three-dimensional schematic diagram of an embodiment of the melamine container of the present invention, a front schematic diagram, a cross-sectional schematic diagram, a partial cross-sectional enlarged schematic diagram, and a simple schematic diagram of the process. The shape of the melamine container 1 is not limited, including such as a bowl , cups, plates, bowls, pots, tubes, bottles and other daily necessities, and its structure mainly includes a melamine primary material part 10 formed by melamine (melamine) powder / granular material 10a through a hot pressing process, and a melamine primary material part 10 formed by melamine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com