Coal combustion product cements and related methods of production

A combustion product, coal combustion technology, applied in cement production, clinker production, etc., can solve the problems of continuous dependence on limited economic and environmental advantages, and achieve the effect of low environmental impact and simple process steps

Inactive Publication Date: 2008-10-29

CALSTAR CEMENT

View PDF2 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although reduced-cost cements have been prepared as partial replacements for Portland cement by the addition of materials such as fly ash, slag, silica fume, zeolites and pozzolans, the continued reliance on Portland cement has shown only limited promise. Economic and Environmental Advantages

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

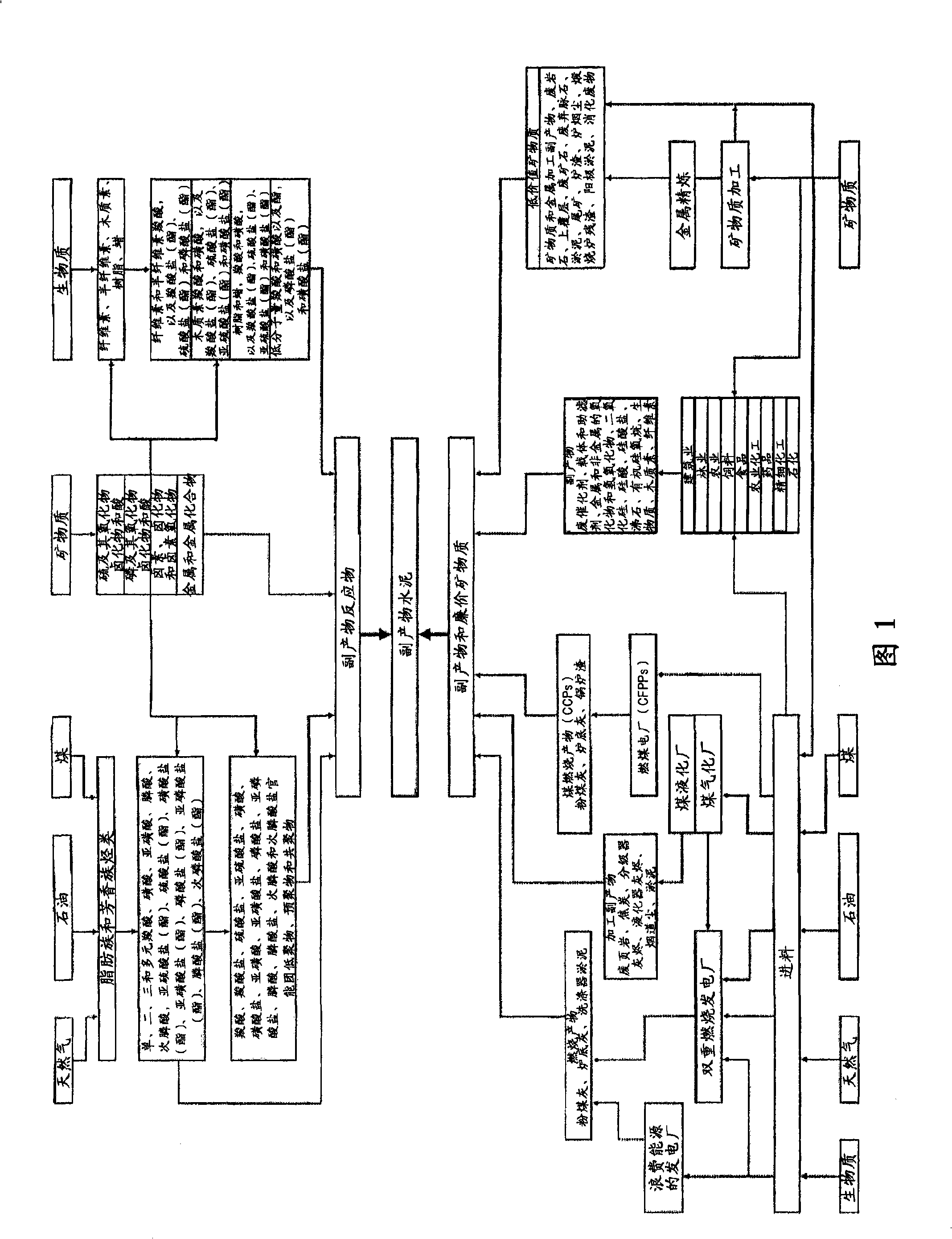

Coal combustion product cement compositions produced using classes of relatively low-cost industrial by-products and low-value minerals. A variety of highly sustainable cements with low-environmental impact can be provided. Coal combustion by-products and other wastes produced on the large scale from the burning of coal or coal and biomass in coal-fired power stations with or without low-value minerals, processed minerals, and / or by-products of the mining, mineral processing, metal refining, petrochemical, fine chemical, pharmaceutical, agrochemical, biotechnology, food, feed and energy industries, as well as agricultural and municipal by-products, can be utilized to provide improved cements and cementitious materials that are more economic and environmentally friendly than traditional cements including Portland cement.

Description

Coal combustion product cement and related production method This application claims the benefit of priority from US Provisional Application US60 / 914021 filed April 25, 2007 and is incorporated by reference in its entirety. technical field The technical field of the application relates to low cost cement produced from low value minerals and by-products of mining, industry, agriculture and municipalities. More specifically, the present application relates to cement formed from coal combustion products, such as fly ash, which are sufficient as practical substitutes for Portland cement. Background technique The construction industry has long been characterized by its vital reliance on Portland cement, a material dating back two centuries, prepared through a technically primitive production process. The production of Portland cement is energy-intensive, uses large amounts of non-renewable resources, and is a major contributor to the world's greenhouse gas emissions. Althoug...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B7/26C04B7/28C04B12/02C04B7/06C04B7/36

CPCY02P40/10Y02P40/121

Inventor M·波拉特I·吉尔S·比林顿

Owner CALSTAR CEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com