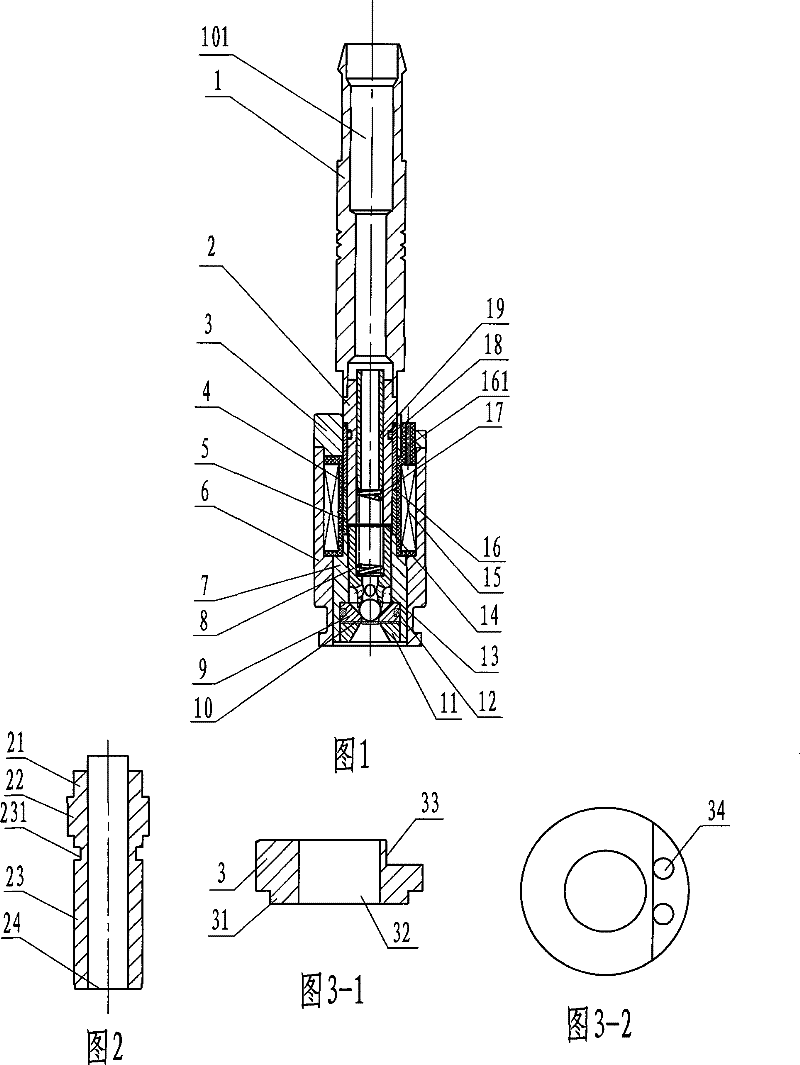

Electronically controlled gasoline injector

A gasoline injector and electronic control technology, which is applied in the direction of machines/engines, fuel injection devices, engine components, etc., can solve the problems of large amount of materials, the structure and processing technology of electronically controlled gasoline injectors are not simple enough, and achieve technological Good performance, saving raw materials and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

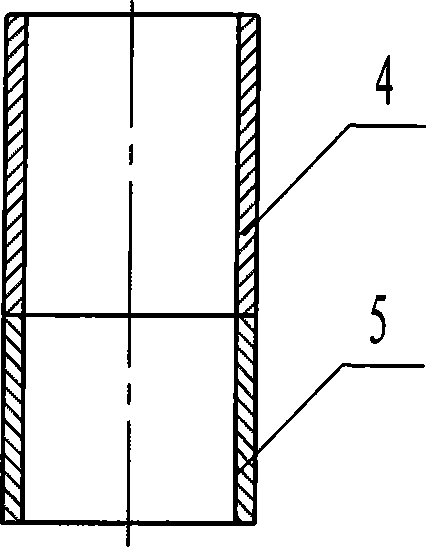

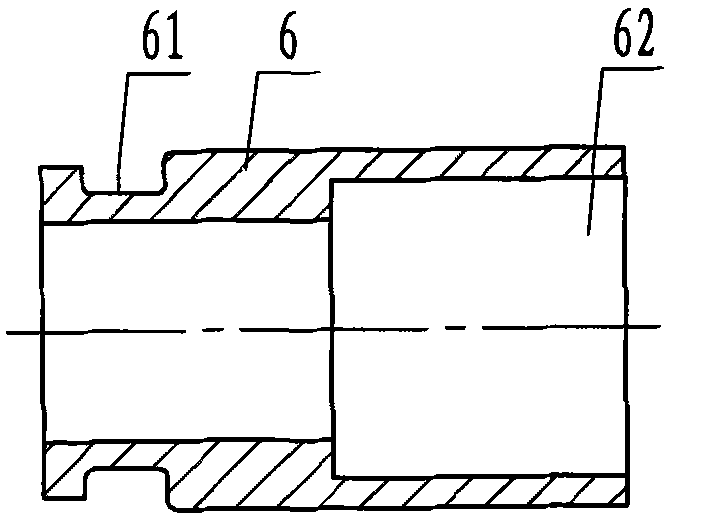

[0034] An electronically controlled gasoline fuel injector is composed of a housing, a valve core, a guide sleeve, a magnetic isolation sleeve, a magnetic guide sleeve, a tube core, an electromagnetic coil, a degaussing structure, an oil inlet pipe, and a spring. The sleeve 7 is installed at one end of the housing 6, and one end of the guide sleeve 7 is also equipped with a valve seat 9, an orifice plate 10, a protective cover 11 and an O-ring 12 in sequence along the axial direction, and the other end of the housing 6 is sequentially installed. Electromagnetic coil 15 with wire frame 16, end cap 3 and tube core 2 inserted in end cap 3 are arranged. End cap 3 is a ring with a boss 31 at its lower end, and a step 33 is arranged at the upper end, and there are two steps on the step. Threading holes 34; tube core 2 is a circular tube with a boss 22 in the middle, the boss part of the tube core is closely matched with the end cover, and the spring 17 is contained in the spool 8 end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com