Industrial process for producing wheat peptide from glutelin powder by enzymic method

A technology of gluten and wheat peptides, applied in food preparation, protein food processing, plant protein processing, etc., can solve the problems of amino acid destruction, difficult final product, difficult to filter, etc., achieve short production cycle, complete enzymatic hydrolysis, easy filter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

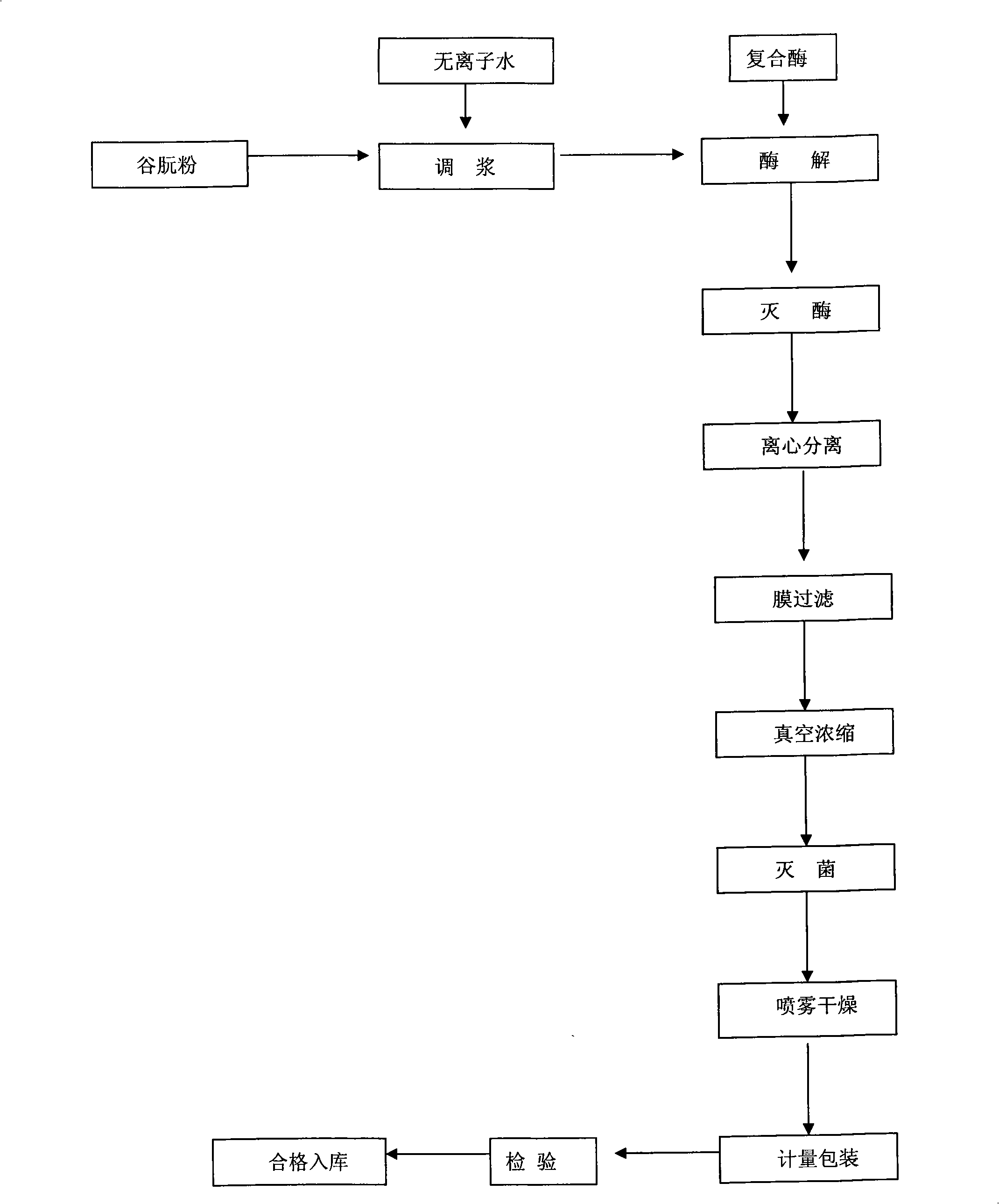

[0017] Accompanying drawing is a kind of specific embodiment of the present invention. Such as figure 1 Shown, the production process of this embodiment is as follows: (1) drop into gluten powder 1kg, add deionized water 11500-11600ml, after feeding intake finishes, shear by the emulsification shearing machine at the bottom of the tank, and return to flow into tank; 2) Heat up to 50-55°C, add lye to adjust the pH of the feed solution to 7.5-8.0, add 1-2g of compound protease (special enzyme for wheat hydrolysis), and start enzymolysis, and the enzymolysis time is 8 hours; (3) Heat up to 80°C for 10 minutes to inactivate enzymes; (4) After centrifugation, filter with ceramic membrane, vacuum concentration concentration is 20%, after sterilization, the material liquid is spray-dried and passed through 60 mesh sieve, measured, packed in compound bags, inspected and put into storage . The raw material requirements for this production method: gluten: moisture ≤ 7.0%, protein ≥ 77...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com