Sunlight hollow board and manufacturing method thereof

An empty board, sunlight technology, applied in the field of sunlight board, can solve the problems of easy damage and easy falling off of the UV absorber protective layer, so as to reduce the production cost and solve the effect of layering and falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

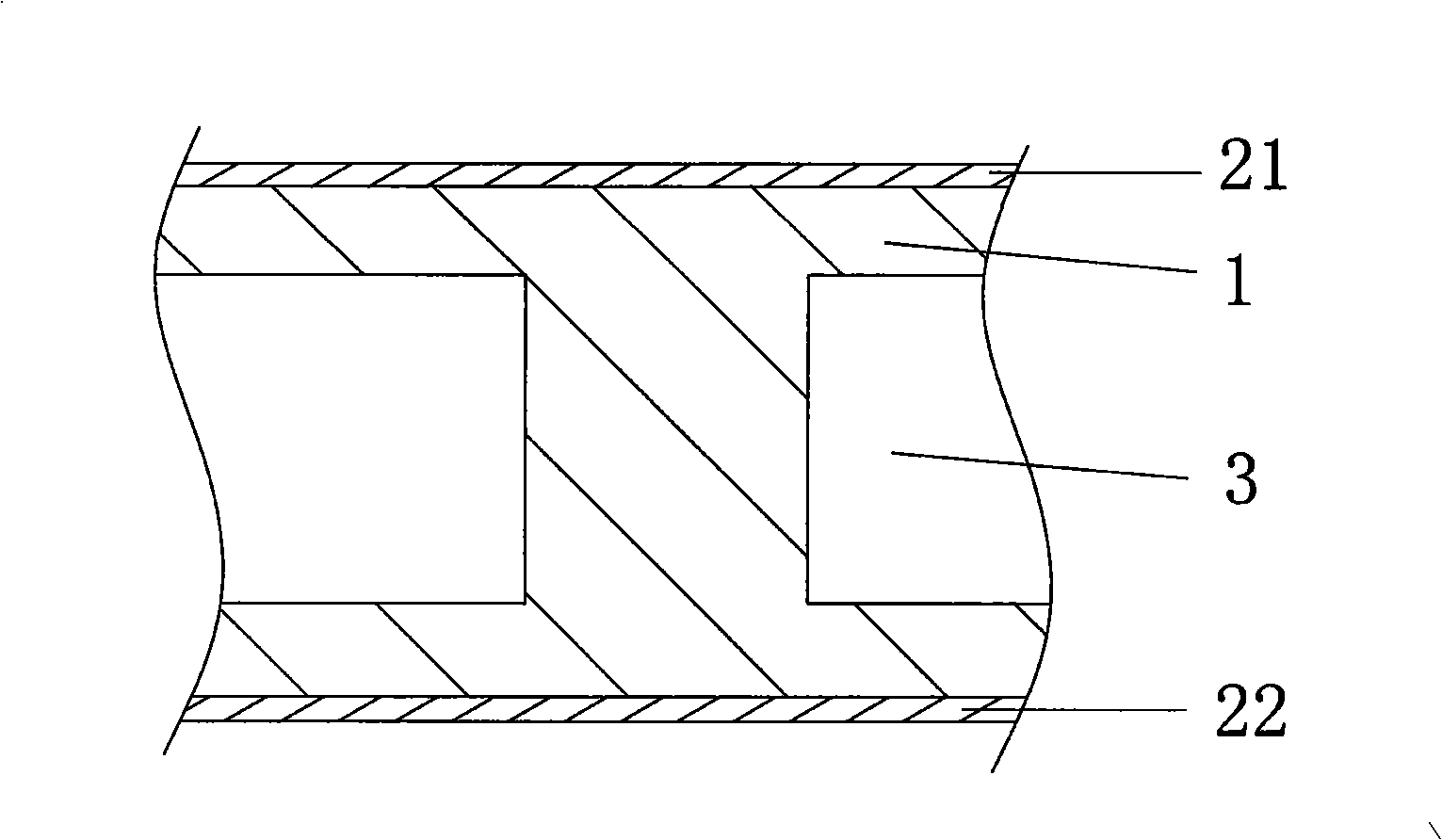

[0020] see figure 1 . A kind of sunshine hollow board, comprising sunshine hollow board body 1, ultraviolet absorber protective layer 21,22, polycarbonate hollow board comprises hollow part 3, hollow part 3 is filled with compressed air; ultraviolet absorber protective layer 21, 22 passes through The extrusion method is used to form the upper and lower surfaces of the sunshine hollow board body, with a thickness of 30 microns to 50 microns. The sunshine hollow board of this embodiment has double-sided ultraviolet absorber protective layers.

Embodiment 2

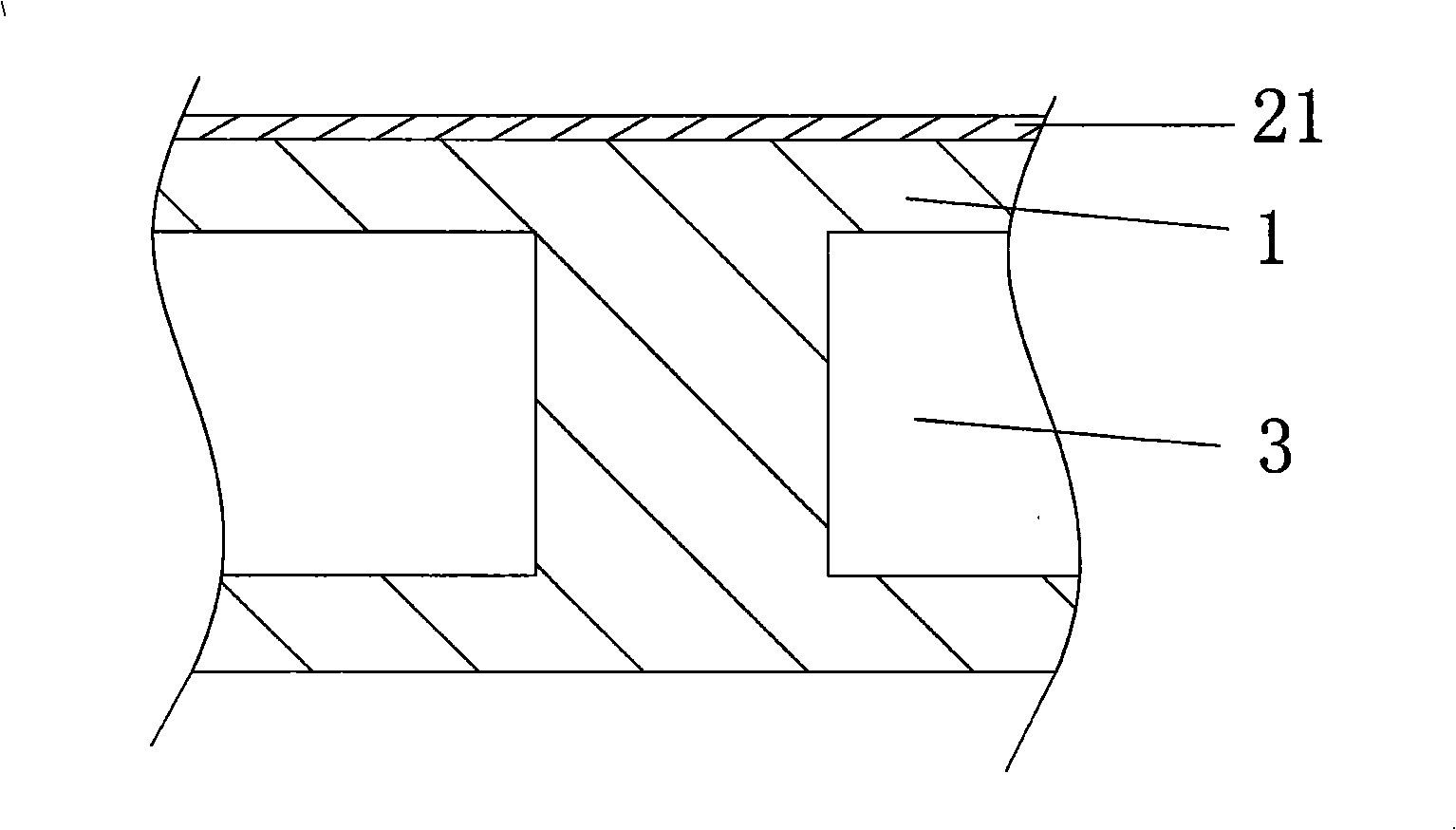

[0022] see figure 2 . A hollow sunlight board, comprising a hollow sunlight board body 1, a UV absorber protective layer 21, the polycarbonate hollow board includes a hollow part 3, and the hollow part 3 is filled with compressed air; the UV absorber protective layer 21 is formed by a co-extrusion method On the upper surface of the solar hollow board body, the thickness is 30 microns to 50 microns. The sunlight hollow board of this embodiment has a single-sided ultraviolet absorber protective layer.

Embodiment 3

[0024] The ultraviolet absorber that adopts is K-6397, manufactures the sunlight hollow plate with 4cm thickness, wherein the thickness of ultraviolet absorber layer is 30 microns. The PC main material and the ultraviolet absorber are melted and extruded in the extruder at 260°C and 240°C respectively, merged in the mold, and shaped by the shaping table. The shaping temperature is 60°C, and the upper and lower sides of the shaping table are vacuumed to increase the surface finish. In addition, compressed air with a pressure of 1.5 Bar is blown into the hollow part through the mold to prevent collapse, and finally annealed at 120°C to obtain qualified products. The details of the annealing stage are as follows: After setting, the temperature is raised to 120°C after 15-20 seconds, and the temperature is maintained at 120°C for 1.2-1.5 minutes, and then naturally cooled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com