Method and instrument for calibrating rotary shaft coaxiality

A calibration method and rotary shaft technology, applied to instruments, measuring devices, optical devices, etc., can solve the problems that cannot meet the installation accuracy requirements of the reel shaft and the high coaxiality requirements of the rotary shaft, etc., and achieve a high degree of automation , improve work efficiency, and achieve high calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

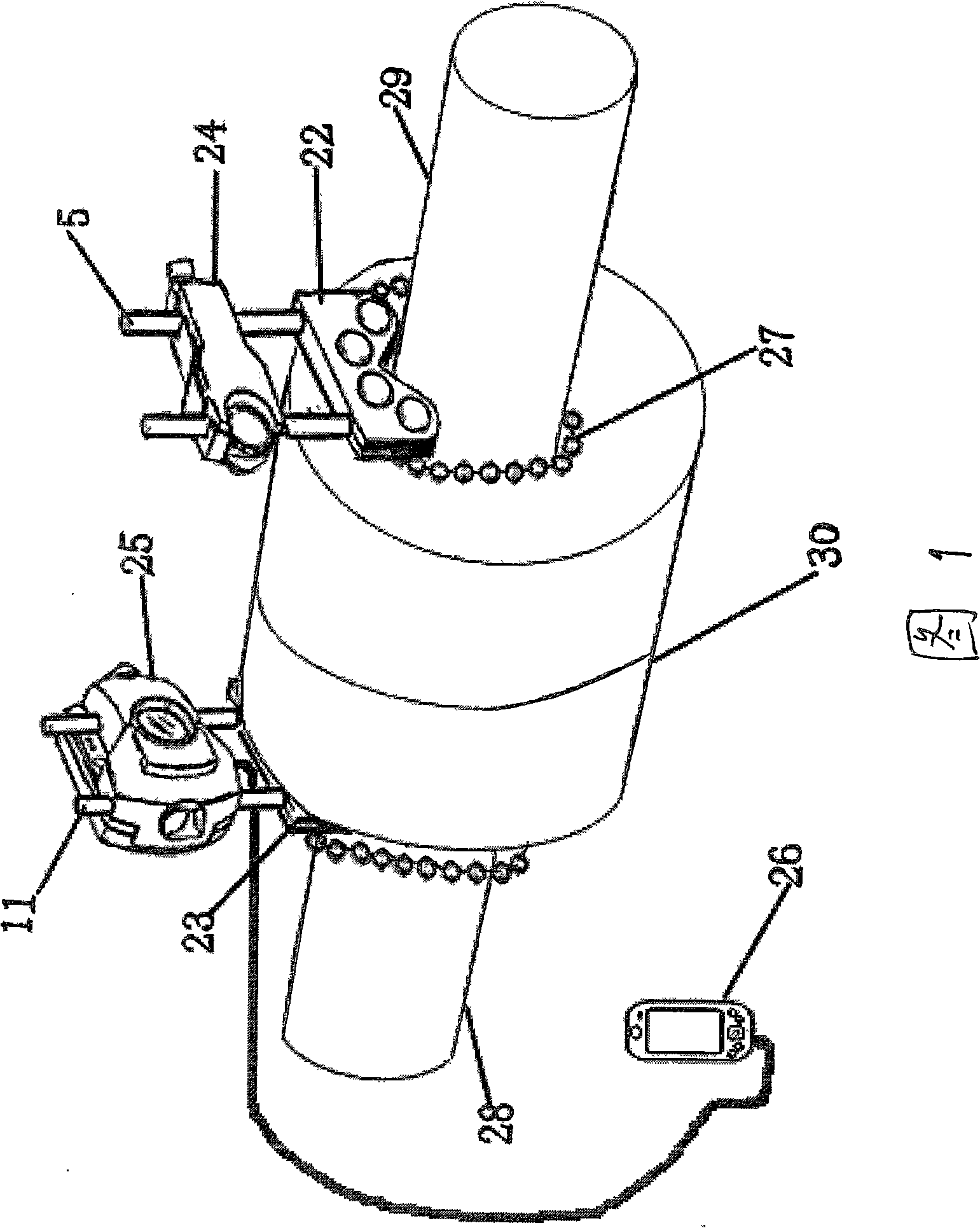

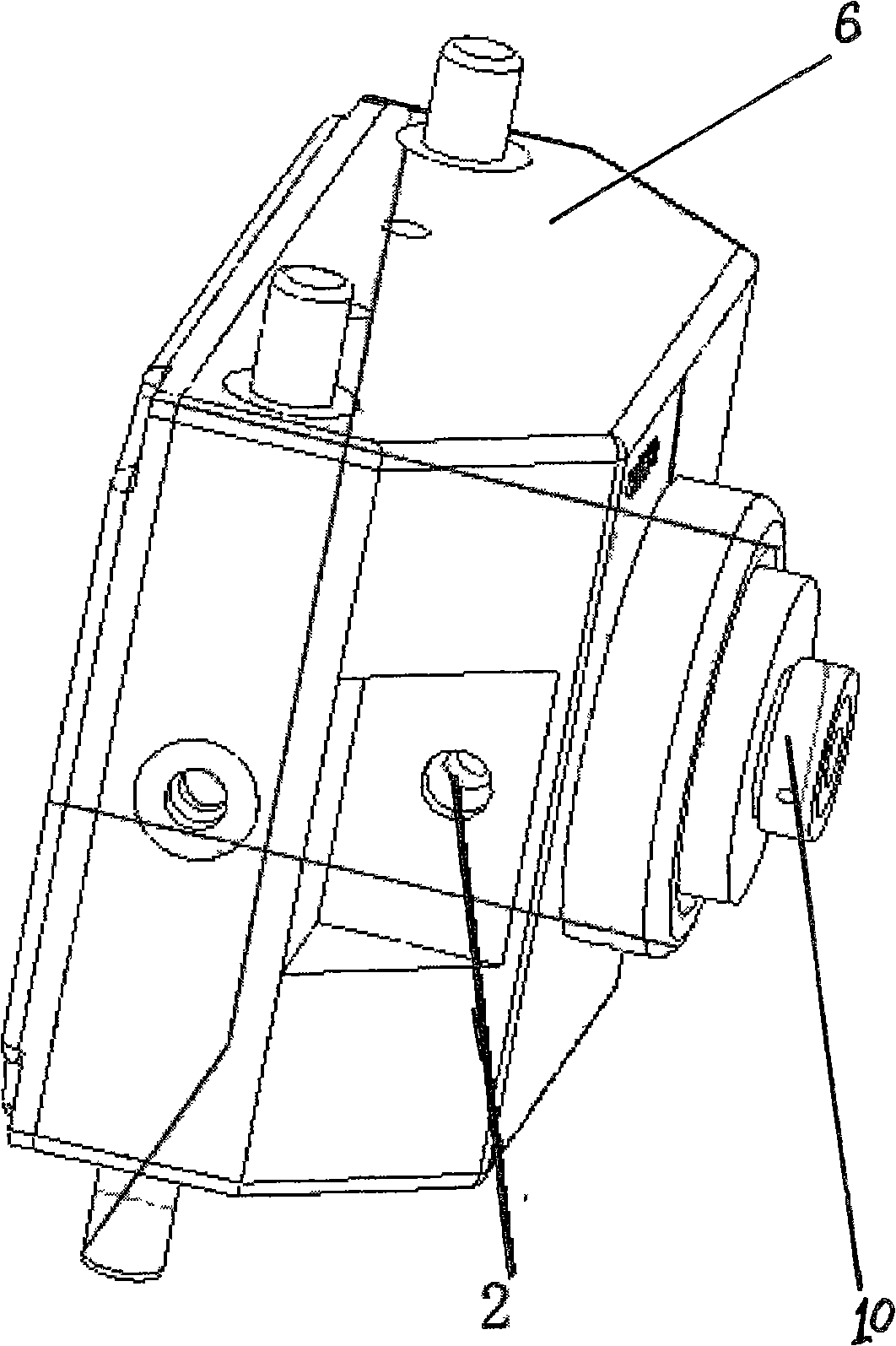

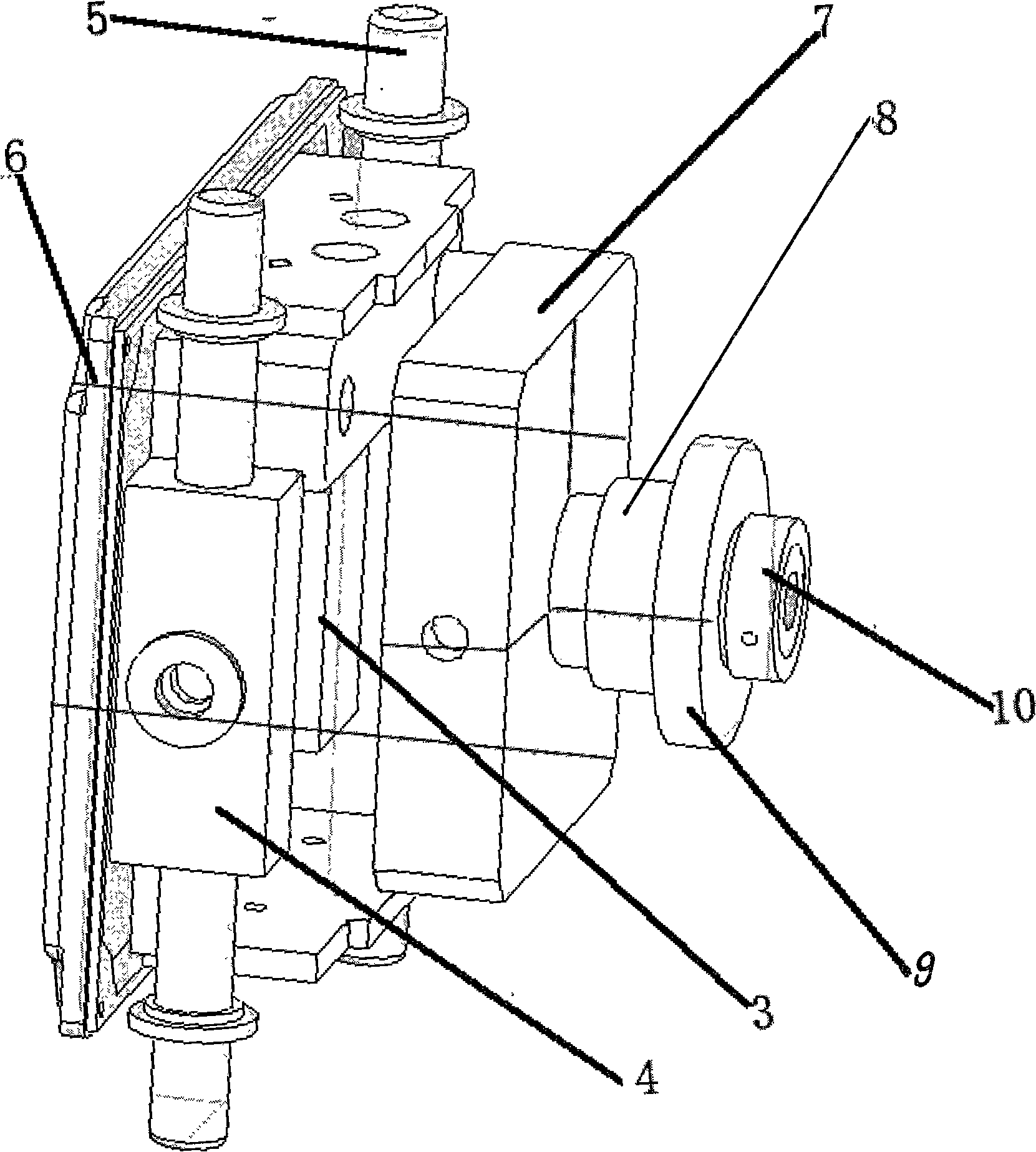

[0014] Refer to Figure 1 to Figure 5 , the method for calibrating the coaxiality of the rotary shaft in the present invention is as follows: firstly, the laser transmitter support and the laser receiver support are respectively fixed on the two rotary shafts to be measured, and then the laser transmitter and the laser receiver are respectively loaded into their respective on the support, and make their heights roughly equal, even if the laser emitted by the laser transmitter falls near the center of the filter (lens) of the laser receiver, and then use a chain to respectively connect the laser transmitter support and the laser receiver support Locked with the two rotating shafts to be tested; then, the laser beam is emitted by the laser collimator of the laser transmitter and directed to the optical filter (lens) in the laser receiver. After the action of the optical filter, only the wavelength 650nm laser (the diameter of the laser beam is less than or equal to 3mm), and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com