Invisible apparatus and design based on geometrical optics

A geometrical optics, invisible technology, applied in optics, optical components, beam optical fibers, etc., can solve the problems of special material requirements and complex structure, and achieve the effect of low cost, simple structure and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

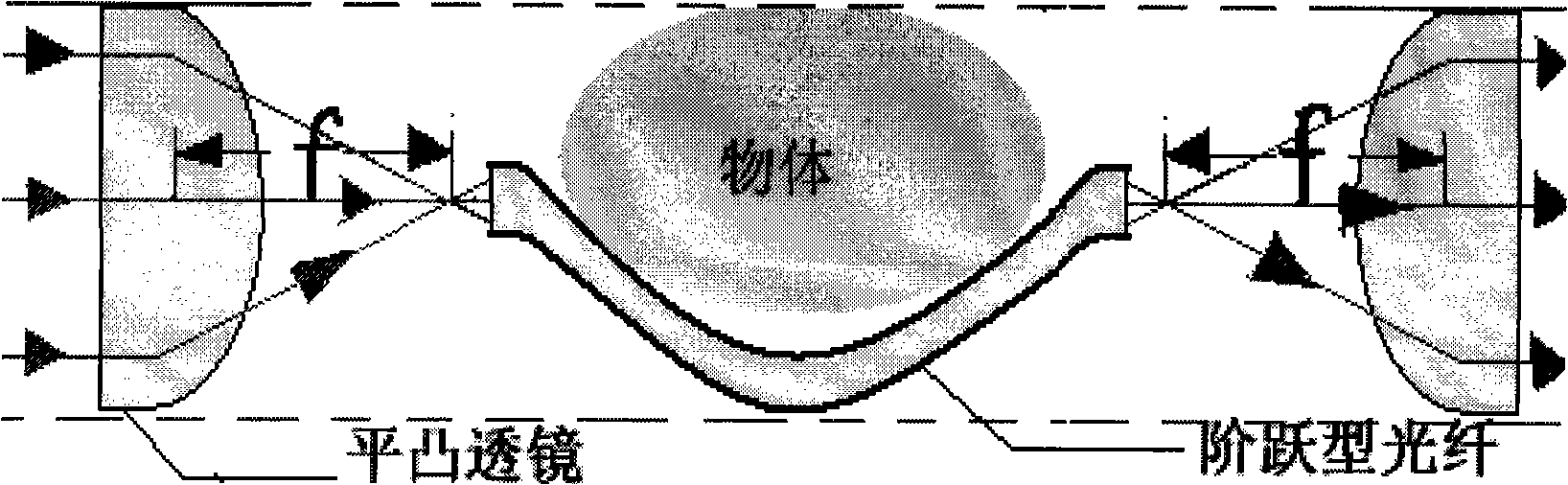

[0053] At least one group is composed of an object group 1 that allows light to pass through and focus it, and a light beam transmission component 2 and an invisible area 3 arranged between the focused object group 1 . Wherein, the object group 1 for focusing light is a plano-convex lens group, and the light beam transmission component is an optical fiber.

[0054] When a beam of parallel light is irradiated to the front of the object, it will be converged into a small beam and injected into one end of the image-transmitting fiber, and then transmitted through the image-transmitting fiber (step-type fiber bundle), (because the fiber is flexible, it can be bent into any Shape, so that it goes around from the front of the object to the back of the object) At the other end of the image transmission fiber, the converged light beam will be emitted and diverged into parallel light, and finally imaged to achieve the invisible effect (as attachedfigure 1 shown).

[0055] In this embod...

Embodiment 2

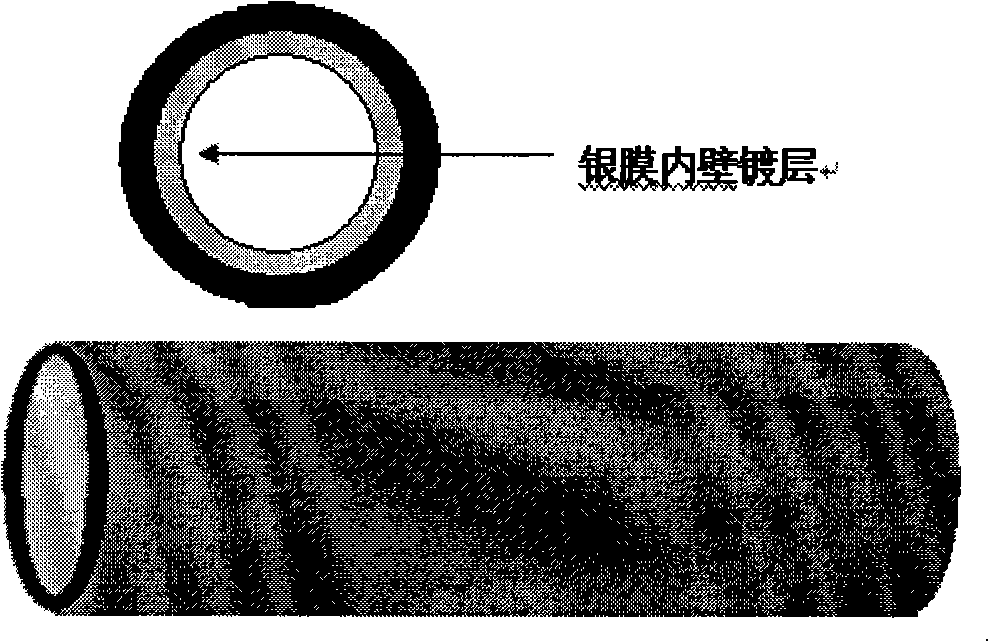

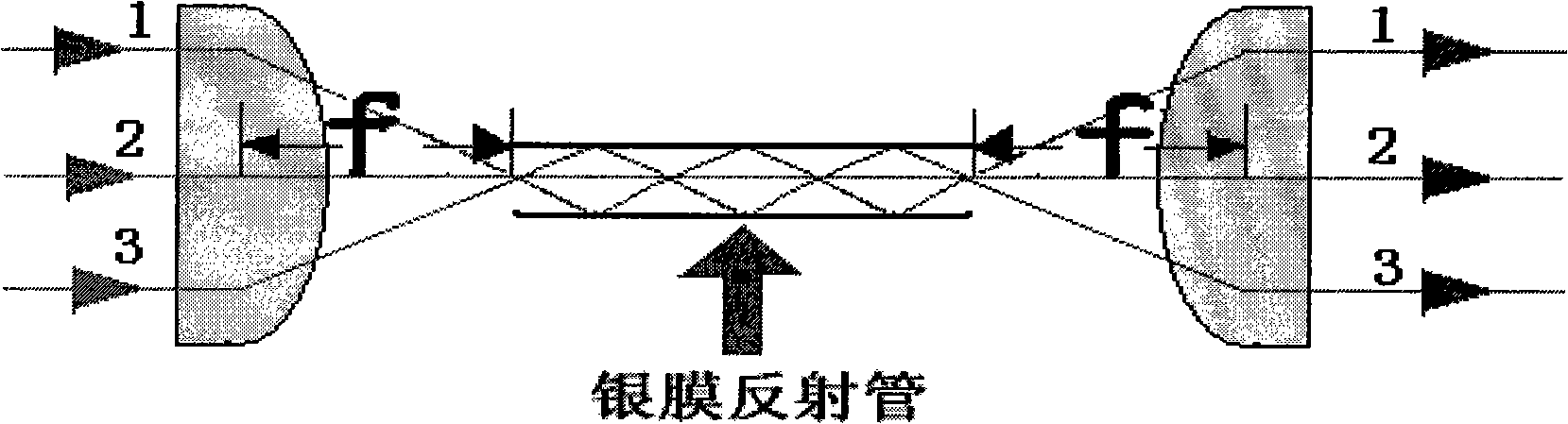

[0057] It is composed of an object group 1 that allows light to pass through and focus it, and a light beam transmission component 2 and an invisible area 3 arranged between the focused object group 1 . Wherein, the object group 1 for light focusing adopts a plano-convex lens group, and the light beam transmission part 2 is a silver film reflection tube. Among them, the structure of the silver film reflection tube is as attached Figure 2a shown; working principle as attached Figure 2b shown.

Embodiment 3

[0059] At least one group is composed of an object group 1 that allows light to pass through and focus it, and a light beam transmission component 2 and an invisible area 3 arranged between the focused object group 1 . Wherein, the object group 1 of the light focusing adopts a plano-convex lens group, and the described beam transmission part 2 is an odd-numbered biconvex lens (lens 4) (as attached Figure 3a shown).

[0060] About the lens (4) is one of the imaging designs of odd-numbered biconvex lenses

[0061] In this embodiment, the setting of lens (4) is a biconvex lens

[0062] 1 piece of biconvex lens imaging design (as shown in the attached picture Figure 3d shown)

[0063] Suppose: the distance between lens 1 and lens 2 is (V1+U2), U2=2f2; the distance between lens 2 and lens 3 is (V2+U3)

[0064] in,

[0065] f1: double the focal length of lens 1; (f1=f3)

[0066] f2: double the focal length of lens 2;

[0067] U1: object distance of lens 1;

[0068] V1: ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com