Silane coating compositions and methods of use thereof

A composition, silane technology, used in anti-corrosion coatings, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

[0063] In this example, by mixing 5 parts of pure bis(trimethoxysilyl-propyl)amine (available from GE Silicones A-1170, www.gesilicones.com ) with 1 part of pure vinyltriacetoxysilane (SIV 9098 from Gelest Inc., www.gelest.com ) to obtain a 5% by volume AV5 silane solution. Add 5 parts of this mixture to 95 parts of deionized (DI) water and mix well. The silane solution was aged for 3 weeks before use. The water-based dispersion of polymer resin was prepared by mixing 70 parts by weight of EPI- 5522-WY-55 (a 55% aqueous dispersion of bisphenol A diglycidyl ether (DGEBA) epoxy resin, available from Hexion Specialty Chemicals, Inc., Columbia, Ohio) with 15 parts polyisocyanate (curing agent) and 0.5 The tin catalyst is prepared in parts by weight. The mixture was then diluted to 50% by volume with n-butoxyethanol. Then, 98 parts by weight of the silane solution and 2 parts by weight of the water-based resin dispersion were mixed to obtain a water-based silane coating c...

Embodiment II

[0069] In this example, by dispersing 5 ml of bis(triethoxysilylpropyl) tetrasulfide (available from GE Silicones) in 95 ml of DI water A-1289, www.gesilicones. com) A 5% by volume solution of A-1289 silane was prepared. Add 4g EPI- WD 510 (water-reducible diglycidyl ether of bisphenol A (DGEBA) epoxy resin (100% resin) available from Hexion Specialty Chemicals, Inc., Columbia, Ohio) in 100 ml of a 5% aqueous mixture of A-1289 , to provide a water-based silane coating composition. The components were mixed with agitation for 24 hours prior to compounding.

Embodiment III

[0071] In an additional third example, by dispersing 5 ml of bis(triethoxysilylpropyl) tetrasulfide (available from GE Silicones) in 95 ml of DI water A-1289, www.gesilicones.com) A 5 volume percent solution of A-1289 silane was prepared. 4g ECO- 9790, a 42% solids dispersion in 7% 2-propoxyethanol, 3% xylene, 3% ethanolamine and 45% water-based acrylic acid was added to 100ml of a 5% aqueous mixture of A-1289 to obtain an aqueous Silane coating composition. The components were mixed with agitation for 24 hours prior to compounding.

[0072] Aluminum alloy (AA 6111) and HDG were cleaned with 7% Chemclean (from Chemetall / Oakite Inc) at 60°C, followed by rinsing with tap water and air drying. The cleaned AA 6111 and HDG panels were dipped in the two silane coating compositions described above (Examples II and III), followed by curing at 150°C for 1 hour.

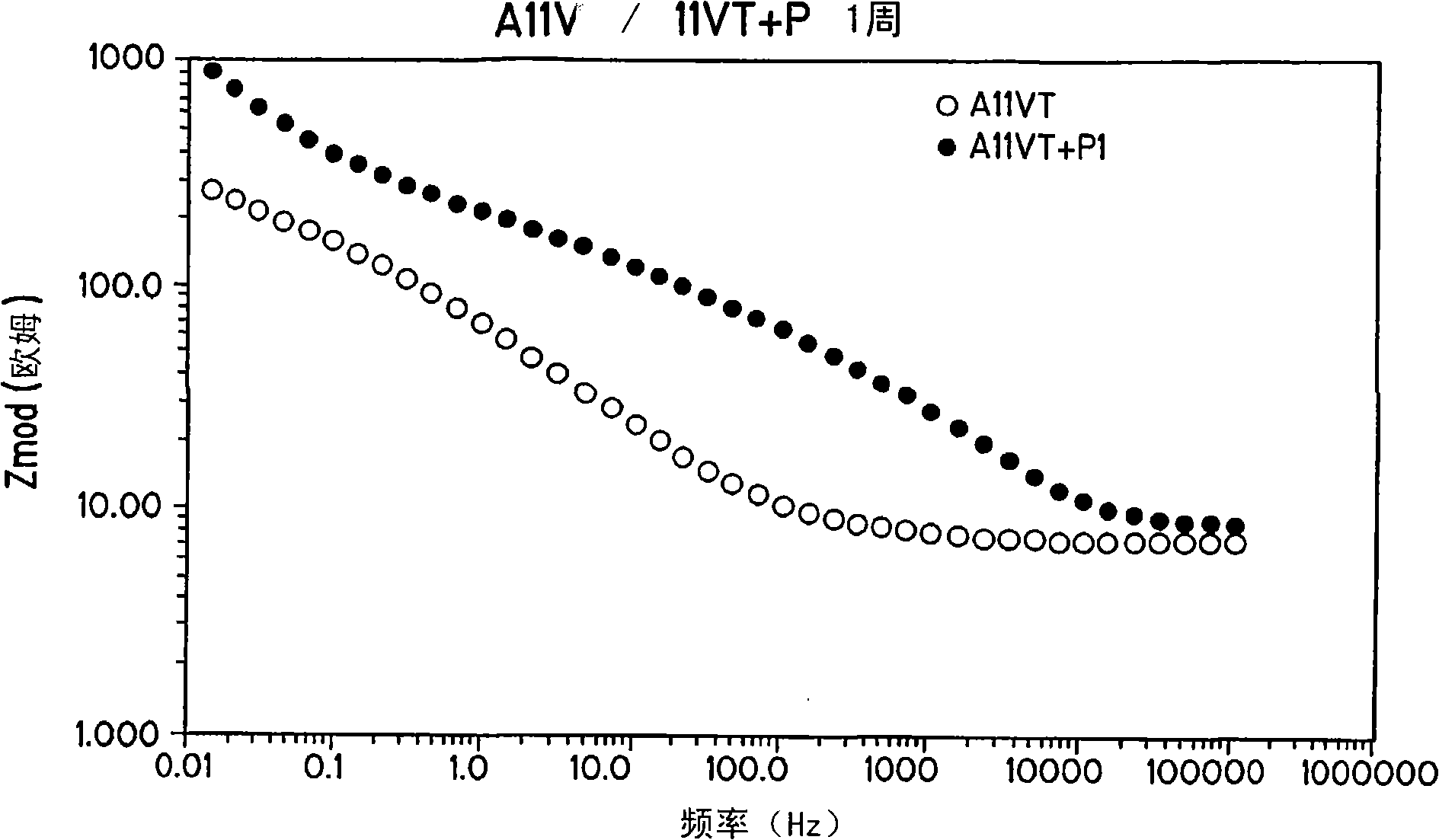

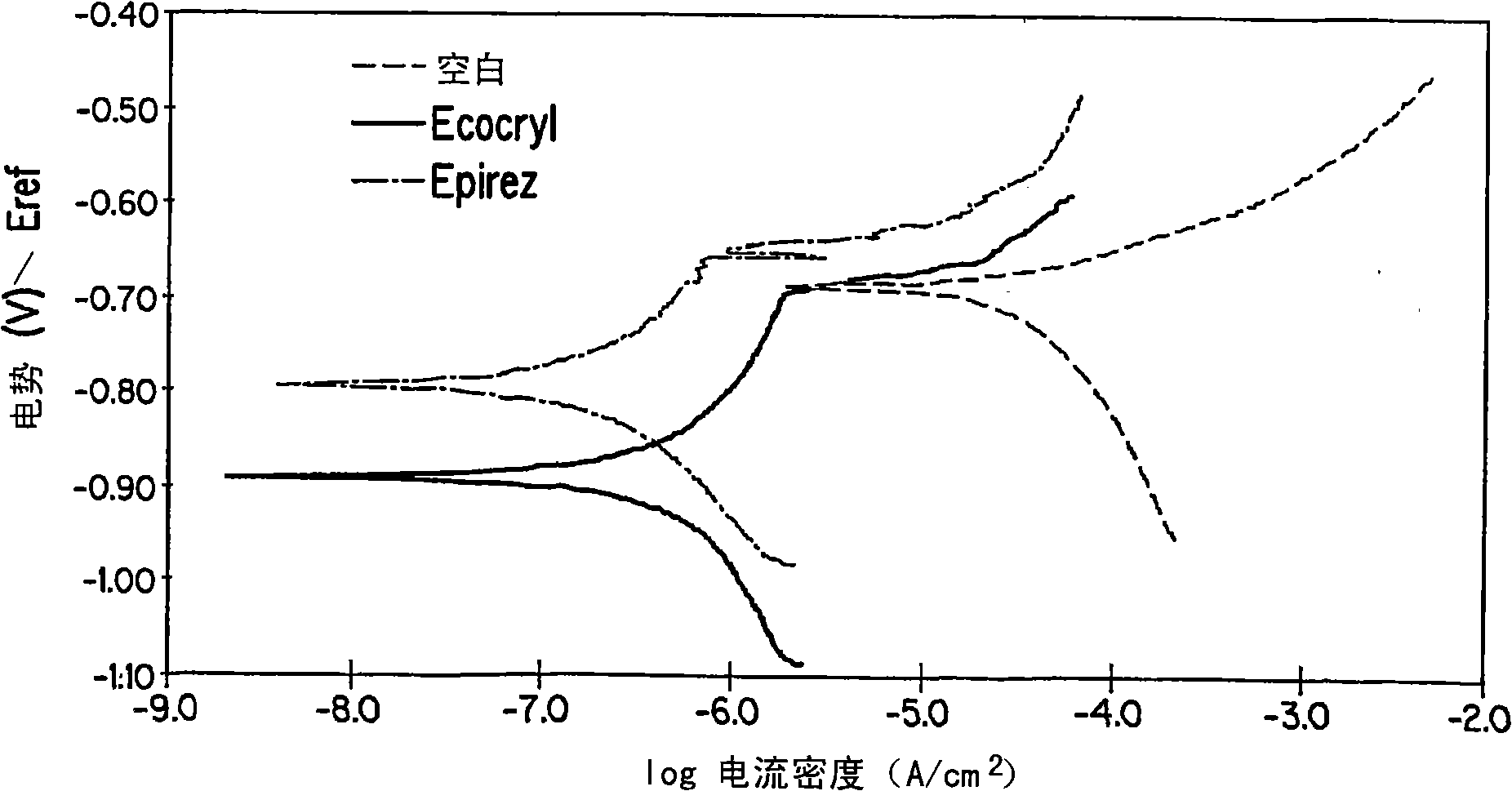

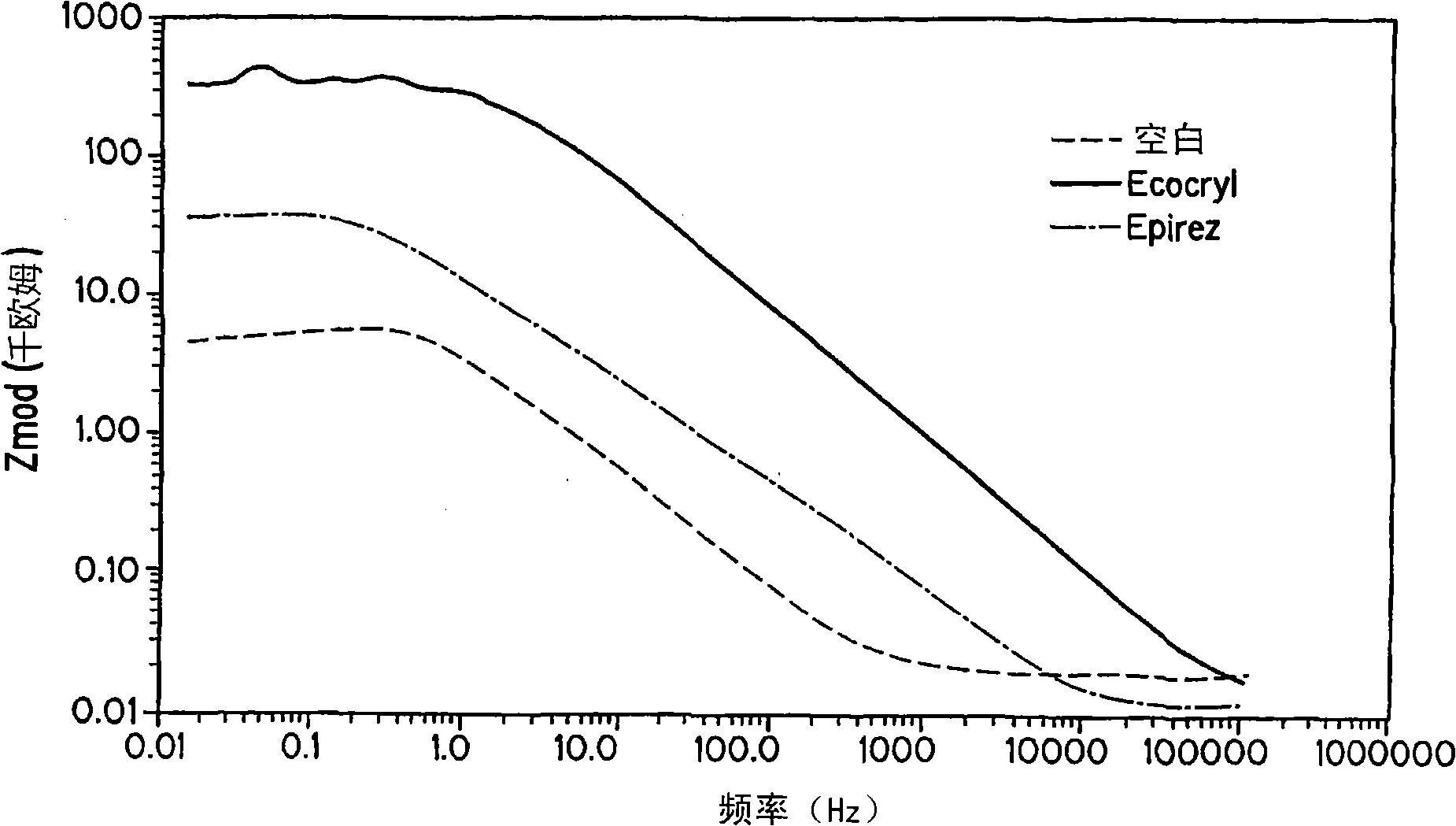

[0073] DC polarization tests and EIS measurements were performed on the above plates in neutral 3.5% NaCl solution. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com