Filling type leaf protein bean curd and method for processing and producing the same

A leaf protein and filling technology, which is applied in dairy products, food preparation, cheese substitutes, etc., can solve the problems of inability to produce canned tofu, limited quality assurance, and inconvenient centralized production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

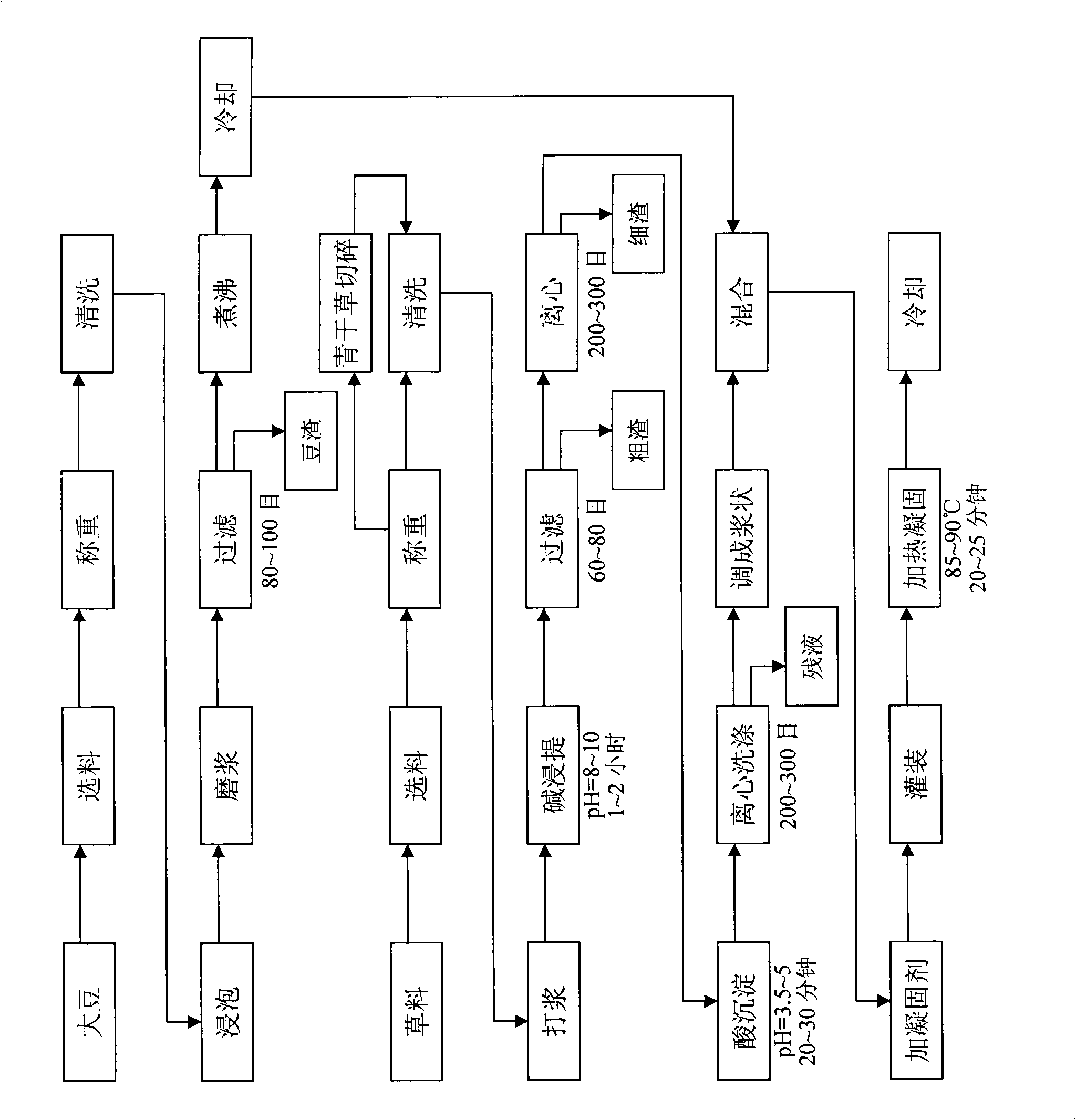

Image

Examples

Embodiment 1

[0031] Adopt fresh alfalfa grass as the leaf protein raw material, and the air-dried weight of the fresh alfalfa grass used and the proportioning ratio of soybean are 40kg: 10kg. First measure the water content of alfalfa fresh grass with a forage moisture meter, which is 81.5% in this example. According to the moisture content of air-dried grass is 18%, the weight of 40kg air-dried grass is converted into fresh grass weight is 178.4kg, then the weight of the two raw materials The ratio is

[0032] Fresh alfalfa grass 178.4kg soybean 10kg

[0033] Processing technology: process and manufacture according to the processing technology shown in the attached drawing. Some steps in the technological process are further described below:

[0034] ●When cleaning fresh grass, it is required to remove sundries and dead branches and leaves.

[0035] ●The amount of raw materials used is based on the weight after cleaning. This example takes by weighing 178.4kg fresh alfalfa grass throu...

Embodiment 2

[0042] The alfalfa green hay is used as the leaf protein raw material, and the ratio of green hay to soybean is:

[0043] Alfalfa green hay 50kg soybean 10kg

[0044] Processing technology: process and manufacture according to the processing technology shown in the attached drawing. Some steps in the technological process are further described below:

[0045] ●When cleaning green hay, it is required to remove sundries and mildew.

[0046] ●The amount of raw materials used is based on the weight after cleaning.

[0047] ●Chop green hay to φ≤1m before beating 2 .

[0048] ●After beating the forage, add NaOH to adjust the pH of the slurry to 9, extract for 2 hours, and stir at a speed of 30 revolutions per minute. Then the slurry is preliminarily filtered with an 80-mesh sieve, and then centrifuged with a 200-mesh screen to obtain a leaf protein dispersion.

[0049] The description of the following steps is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com